SECTION 5 – INSTALLATION INSTRUCTIONS

UL EX3470 ULC EX3470

2014-SEP-01 REV. 11 PAGE 5-43

R-102 Restaurant Fire Suppression Manual

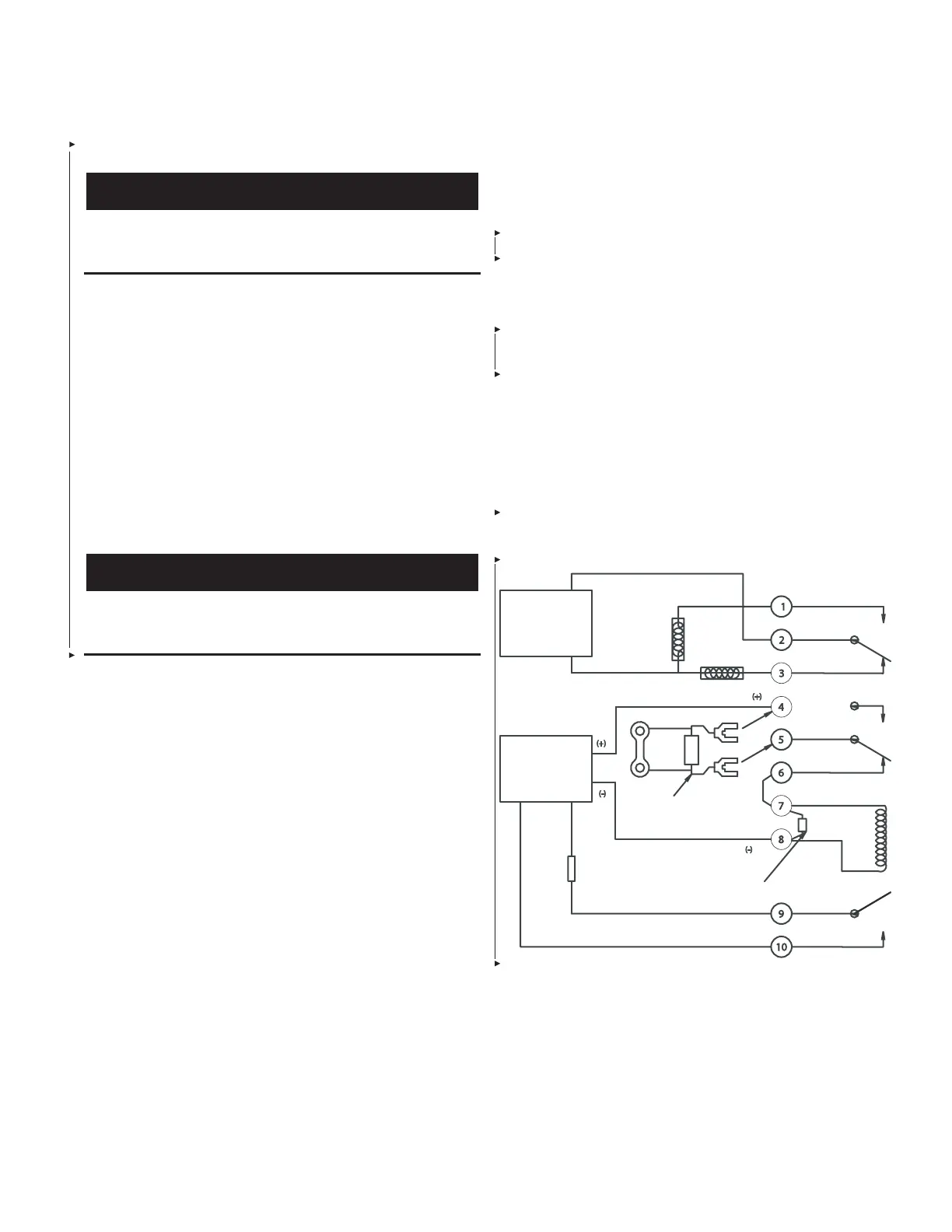

WIRING 24VDC REGULATED RELEASE ASSEMBLY

CAUTION

Do not install cartridge or remove tank assembly unless release

is cocked and ring pin is in place. Failure to comply may result

in accidental system actuation.

If the following occurs during installation, the solenoid for the

releasing assembly may be damaged, rendering the system

inoperable.

1. If the release is electrically tripped (fired) with the ring pin

inserted such that the release mechanism is pinned in the

cocked position.

2. The lever arm of the mounted switch is bent such that the

switch does not operate when the release roll pin is bottomed

out in the fired position.

3. Trying to recock the release mechanism while power is

applied to the release through the alarm contacts.

For complete recharging, inspection, and maintenance instruc-

tions, refer to applicable fire suppression system manual.

!

WARNING

Take extreme care when wiring release assembly. Failure to

comply may cause an electrical shock, resulting in possible

serious injury or death.

Refer to the following notes and wiring diagram for instruction on

wiring the 24VDC regulated release assembly.

Notes:

1. To be connected to a nominal 24VDC releasing circuit.

Input power: 750 mA at 24VDC nominal (1.02 at 30VDC

maximum).

2. Polarization: Observe polarity when connected to a release

circuit; Terminal 4 positive, Terminal 8 negative.

3. All interconnecting wiring number 14 - 18 AWG.

4. S

1

and S

2

contact ratings: 20A, 125/250 VAC 2 HP, 250 VAC

1 HP, 125 VAC.

5. SOL

1

coil resistance: 28 OHMS +/- 10% at 77 °F (25 °C).

6. Install the in-line supervisory device SD

x

across terminals

No. 4 and No. 5. Refer to the releasing panel installation

instructions for supervisory device requirements. If an in-line

supervisory device is not required, install jumper J

2

across

terminals No. 4 and No. 5.

7. S

3

contact ratings: 24VDC, 240mA maximum.

THESE SWITCH CONTACTS TRANSFER UPON

ACTUATION OF RELEASE

HIGH

ACCESSORY

POWER

SOURCE

LOW

*

TB

1

**

UL LISTED

SUPERVISED

RELEASING

CONTROL UNIT

S

1

NC

SD

X

OR

TZ

1

J

1

SOL

1

NC

S

2

VOLTAGE

TRANSIENT

SUPPRESSOR

* AUXILIARY ALARMING DEVICES, SEE S

1

RATINGS

** FUEL SHUT-OFF VALVE, BLOWER MOTOR, DOOR CLOSER, ETC., SEE S

1

RATINGS.

IN-LINE

SUPERVISORY DEVICE

FIGURE 5-125

008468

Loading...

Loading...