SECTION 8 – MAINTENANCE EXAMINATION

UL EX3470 ULC EX3470

2014-SEP-01 REV. 11 PAGE 8-7

R-102 Restaurant Fire Suppression Manual

12-YEAR MAINTENANCE EXAMINATION (Continued)

9.

!

CAUTION

Safety glasses should be worn during transfer operations

of ANSULEX Low pH Liquid Fire Suppressant. Avoid

contact with skin or eyes. In case of contact, flush immedi-

ately with water for 15 minutes. If irritation persists, contact

a physician. Do not take internally. If taken internally do

not induce vomiting. Dilute with water or milk and contact

a physician.

Pour the liquid agent from the tank into a clean, plastic

container, and flush tank with clear water.

10. At this point, each liquid agent tank, including the 1/4 in.

gas hose assembly, must be HYDROSTATICALLY

TESTED to 330 psi (26.6 bar). Refer to “Hydrostatic Test

Instructions,” F-7602, for test adaptors and instructions.

NOTICE

DO NOT hydrostatically test a red painted

mild steel agent storage tank. Instead,

replace the tank with a new stainless

steel tank shipping assembly (3 Gallon

(Part No. 429862) or 1.5 Gallon (Part No.

429864)).

11. Verify date stamped on cartridge. The cartridge must also

be hydrotested at intervals not greater than 12 years.

(European cartridges are not refillable, therefore cannot be

hydrotested and refilled. They must be discarded).

12. If cartridge date indicates the need for hydrotesting, the

cartridge must be bled down through normal AUTOMAN

release operation, returned to Tyco Fire Protection Products

for credit (or hydrotested by properly trained personnel at

authorized cartridge refilling stations), and replaced with a

charged, replacement cartridge.

NOTICE

Cartridge bleed down can be used to

verify pneumatic accessories operation.

13. If system contains an Agent Distribution Hose and

Restraining Cable Assembly, a hydrostatic test is required

at 220 psi (15.2 bar) for hose assembly.

14. The regulator must be flow tested at 12 year intervals.

Check the date code stamped on the regulator body to

determine if the regulator(s) requires the 12 year testing

(see data code table). If regulator does not require testing,

proceed to step 12. Flow test the regulator(s) per the follow-

ing table:

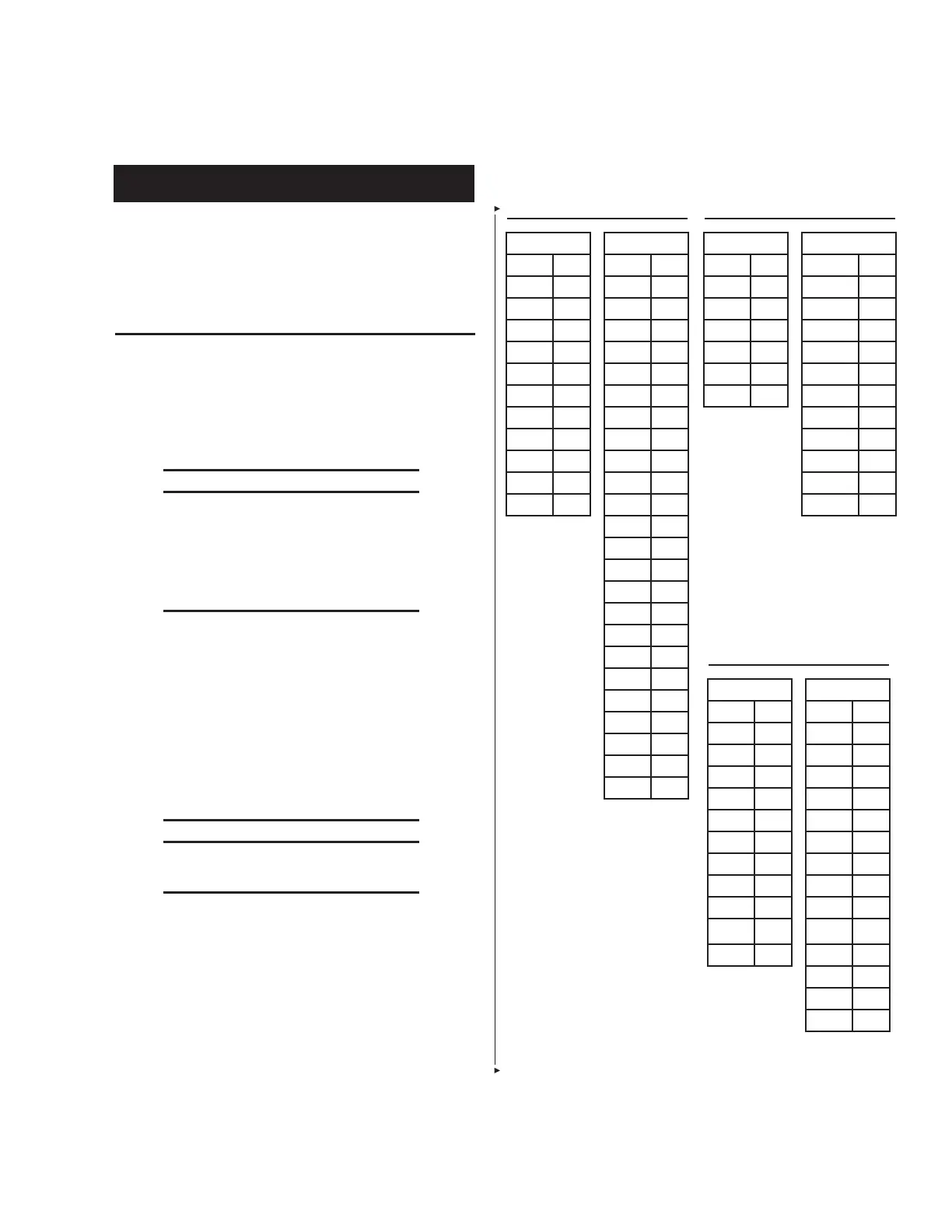

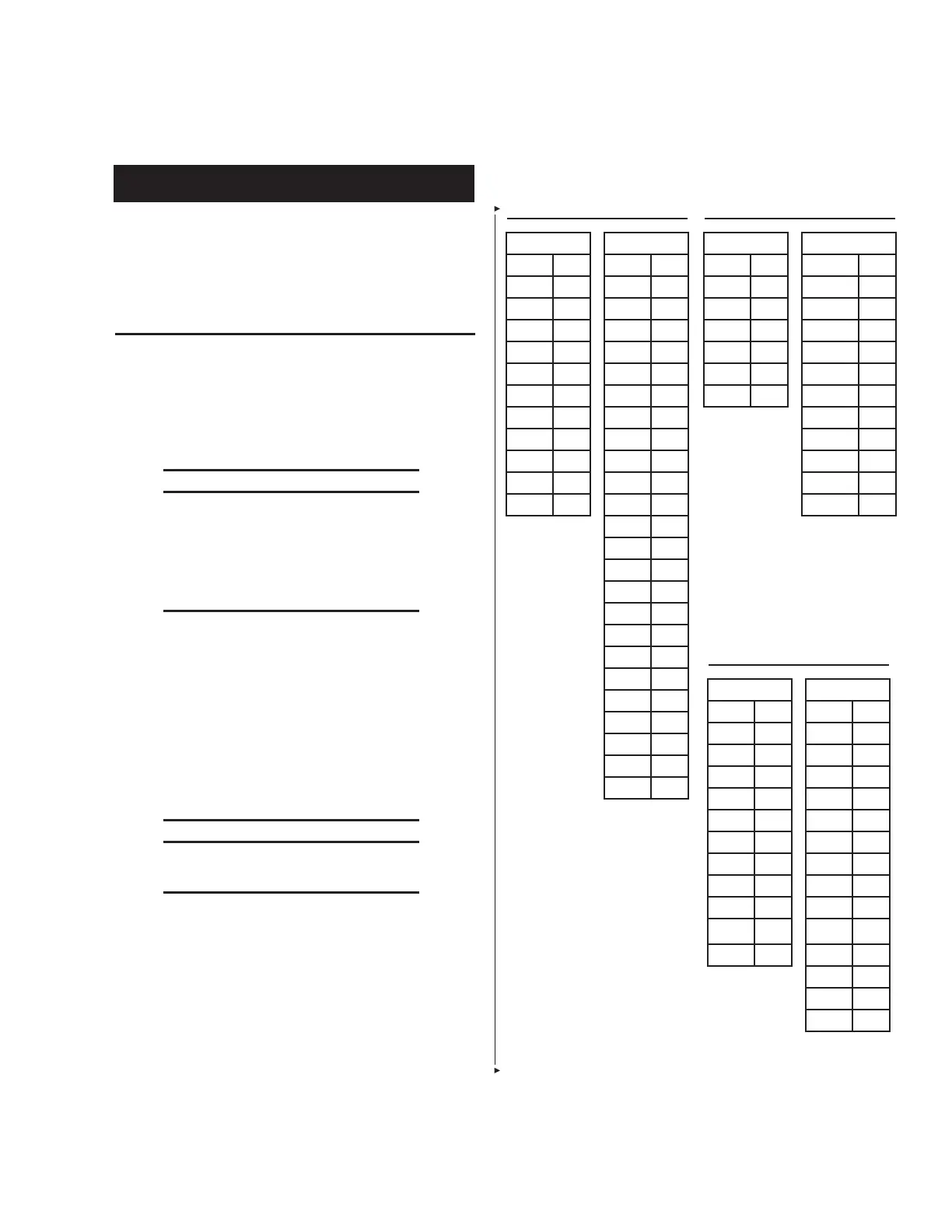

Date Code Table

UL 74FF

Month* Year*

Jan A 2011 T

Feb B 2012 U1

Mar C 2013 U2

Apr D 2014 U3

May E 2015 U4

Jun F 2016 U5

Jul G 2017 U6

Aug H 2018 U7

Sep J 2019 U8

Oct K 2020 U9

Nov L 2021 V1

Dec M 2022 V2

2023 V3

2024 V4

2025 V5

UL 541L

Month* Year*

Jan A 1981 K

Feb B 1982 L

Mar C 1983 M

Apr D 1984 N

May E 1985 P

Jun F 1986 R

Jul G 1987 S

Aug H 1988 T

Sep J 1989 U

Oct K 1990 V

Nov L 1991 W

Dec M 1992 Y

1993 Z

1994 A

1995 B

1996 C

1997 D

1998 E

1999 F

2000 G

2001 H

2002 J

2003 K

2004 L

2005 M

UL 74FF

Year* Month**

2005 E Jan A

2006 F Feb B

2007 G Mar C

2008 H Apr D

2009 I May E

2010 J Jun F

2011 K Jul G

Aug H

Sep I

Oct J

Nov K

Dec L

*STAMPED YEAR 1ST, MONTH

2ND

**STAMPED “I” FOR SEPTEMBER

*STAMPED MONTH 1ST, YEAR

2ND

*STAMPED MONTH 1ST, YEAR

2ND

Loading...

Loading...