SECTION 8 – MAINTENANCE EXAMINATION

UL EX3470 ULC EX3470

PAGE 8-6 REV. 11 2014-SEP-01

R-102 Restaurant Fire Suppression Manual

12-YEAR MAINTENANCE EXAMINATION

In addition to performing all of the steps necessary for semi-an-

nual and annual maintenance, the following twelve-year mainte-

nance procedures for single, double, and multiple-tank systems

must be performed.

NOTICE

Under certain circumstances hood and duct

cleaning operations may render your fire

suppression system ineffective due to a

coating of cleaning chemical left on the detec-

tion equipment or mishandling of the system

by cleaning service personnel.

Therefore, it is strongly recommended that

the R-102 system be completely inspected

and serviced by an authorized ANSUL

distributor immediately following any

such cleaning operations.

At twelve-year intervals, the liquid agent

tank(s) must be hydrostatically tested and

refilled with a fresh charge of ANSULEX

Low pH Liquid Fire Suppressant. The date of

manufacture is stamped on the bottom of the

agent tank or on the tank label.

1. Remove the enclosure cover from the AUTOMAN

regulated release assembly and each regulated actuator

assembly.

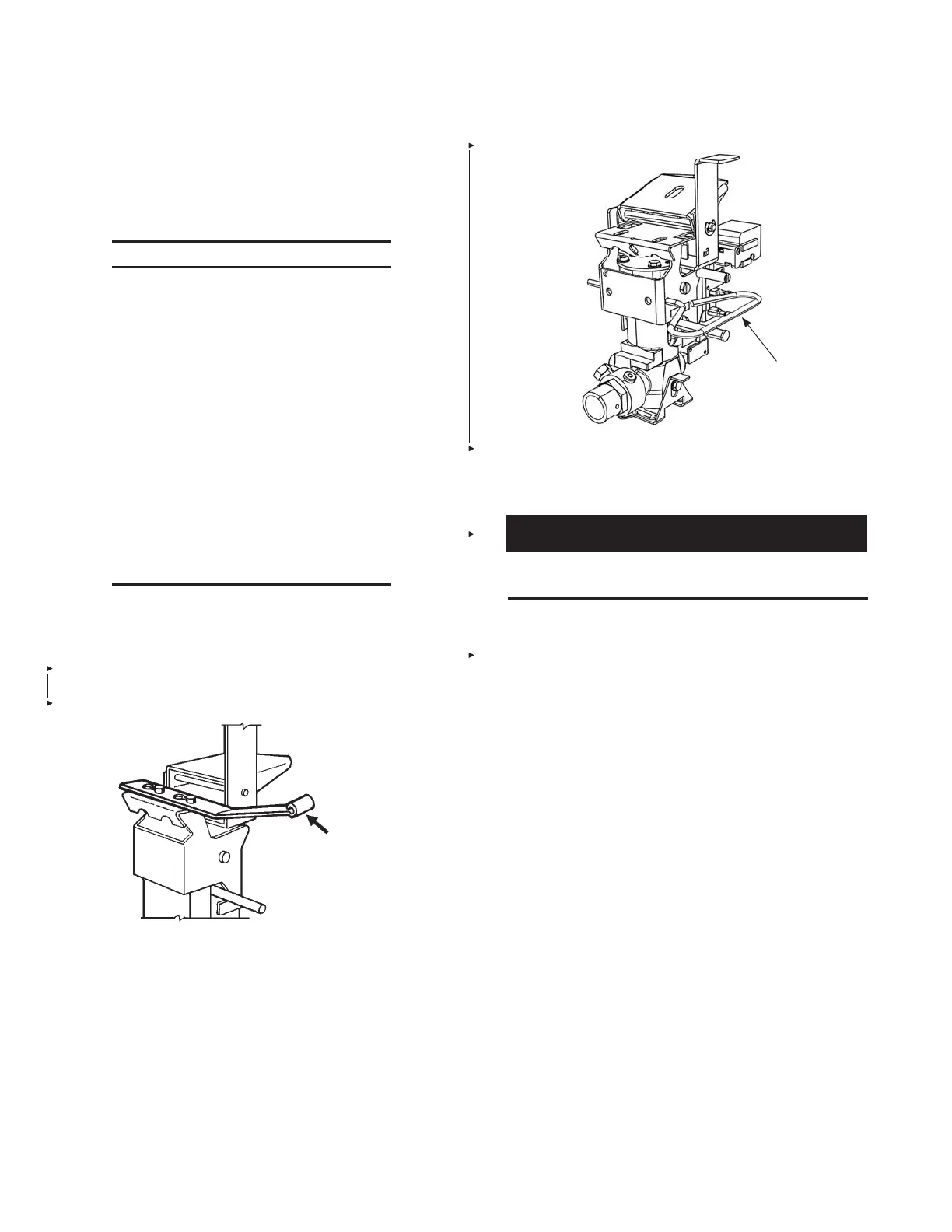

2. Insert the lock bar (Part No. 14985) or lock pin (Part No.

438031) on the cocked regulated release mechanism. See

Figure 8-9 or Figure 8-10.

LOCK BAR

PROPERLY

INSTALLED

FIGURE 8-9

000321

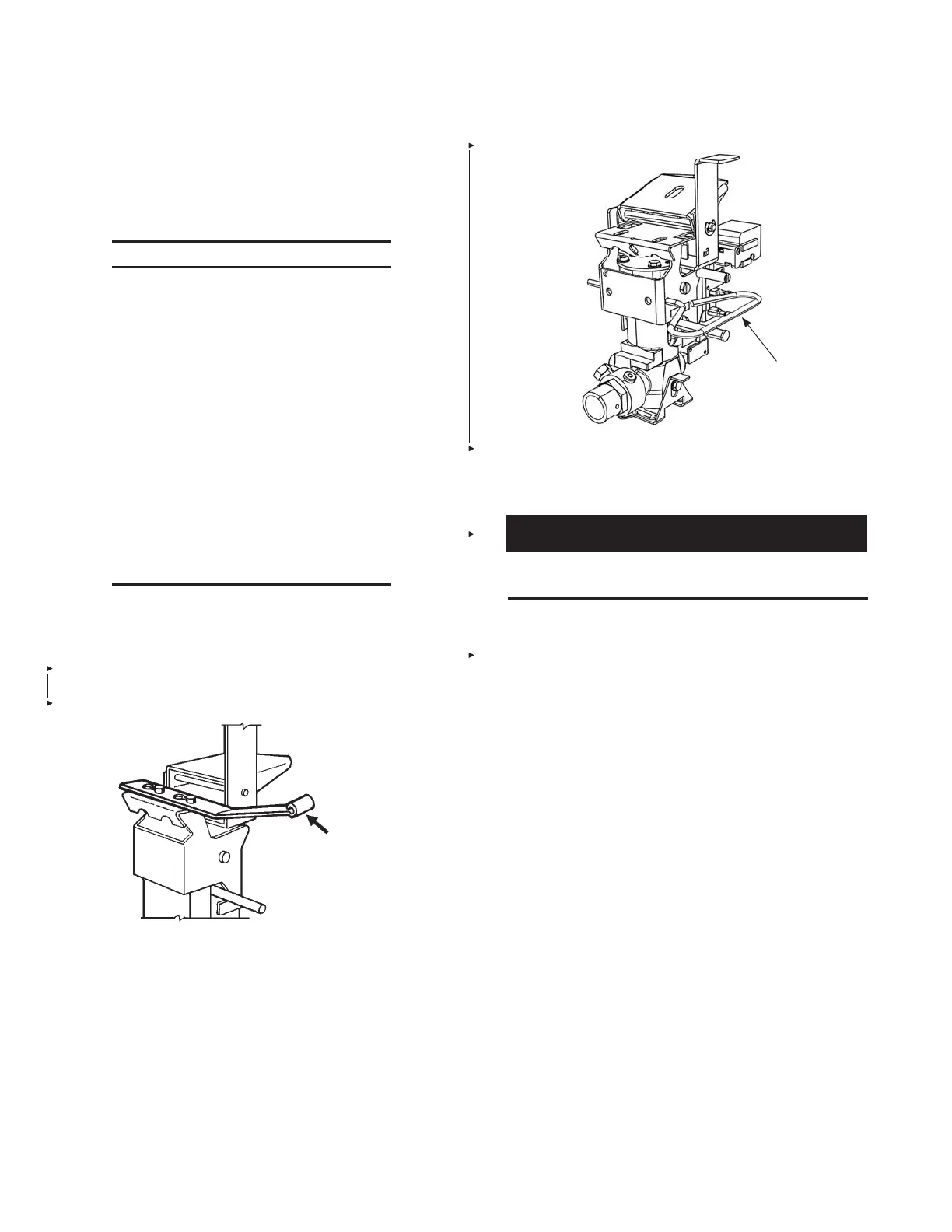

FIGURE 8-10

009462

3. Remove cartridge from regulated release assembly and

each regulated actuator assembly, install safety shipping

cap, and set aside in a safe location.

CAUTION

Do not reinstall cartridge at this time or system may be

actuated.

4. Remove gasket from cartridge receiver in regulated release

mechanism and each regulated actuator. Check gasket for

elasticity or cuts and replace Gasket (Part No. 181) if neces-

sary. Clean and coat gasket lightly with a good grade of

extreme temperature grease. Reinstall gasket into cartridge

receiver(s).

5. From tank in enclosure: Disconnect the expellant gas piping

or hose from each tank adaptor assembly.

From tank in bracket assembly: Disconnect expellant gas

piping union at each tank adaptor inlet line.

6. Disconnect distribution piping union at each tank adaptor

outlet line.

7. From tank in enclosure: Remove tank.

From tank in bracket assembly: Loosen wingnut, disengage

bracket band, and remove each tank. Keep tank in upright

position to avoid spilling the agent.

8. Loosen tank adaptor/tube assembly and remove.

LOCK PIN

PROPERLY

INSTALLED

Loading...

Loading...