Horizontal Chain Broiler Protection (Continued)

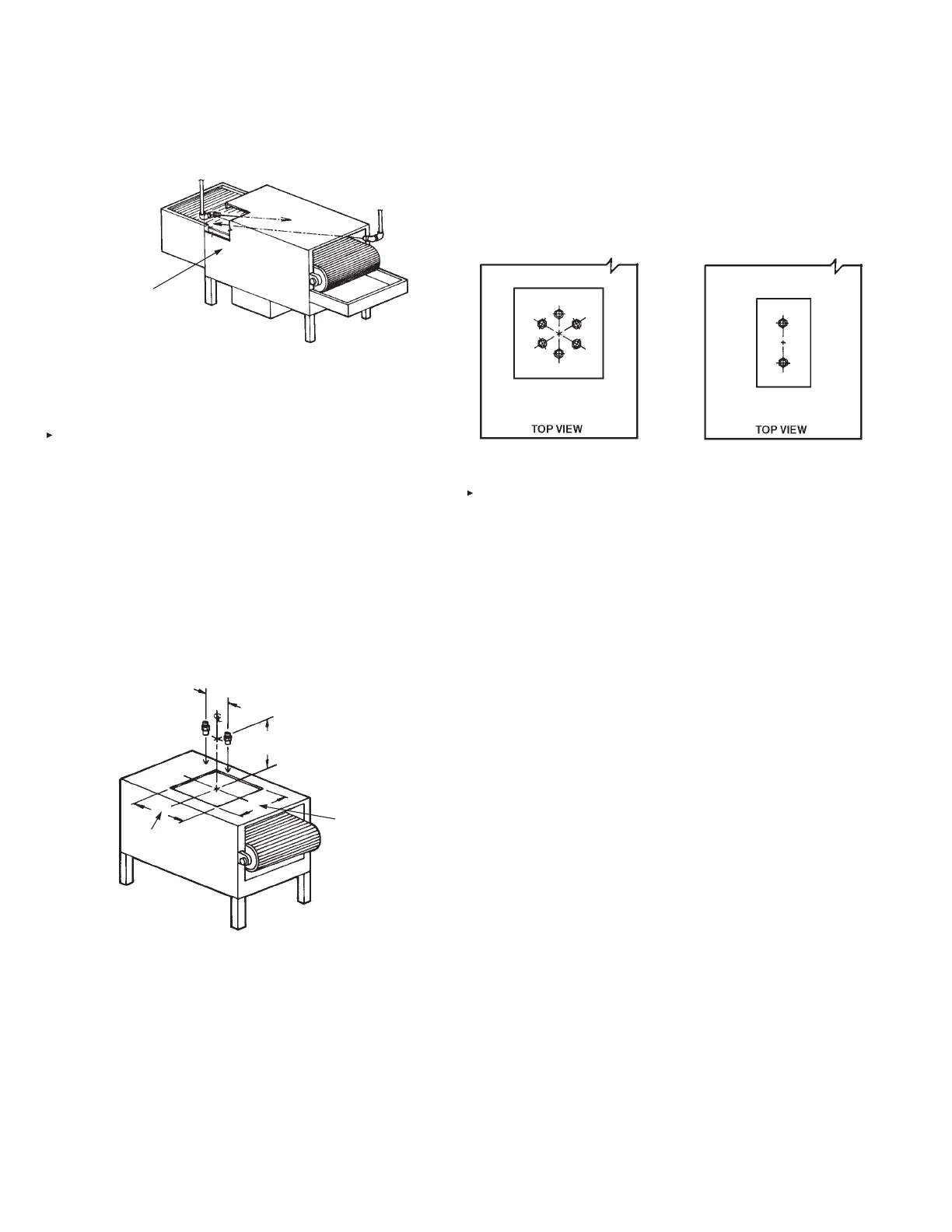

FIGURE 4-54

000247

Overhead Chain Broiler Protection

The R-102 system can use two 1W nozzles for overhead chain

broiler protection. The nozzle is stamped with 1W, indicating

that this is a one-ow nozzle and must be counted as one ow

number.

Overhead protection is only available for chain broilers with

exhaust opening dimensions that are not less than 60% of the

internal broiler length and not less than 60% of the internal

broiler width, to a minimum size of 12 in. x 12 in. (305 mm x

305 mm). Internal broiler size can not be larger than 32 in. x

34 in. (812 mm x 863 mm).

When overhead protection is used, the nozzles must be

centered above the exhaust opening within 4 to 8 in. (101 to 203

mm) of each other and they must be located 10 to 26 in. (254 to

660 mm) above the top of the broiler surface. See Figure 4-55.

FIGURE 4-55

000248

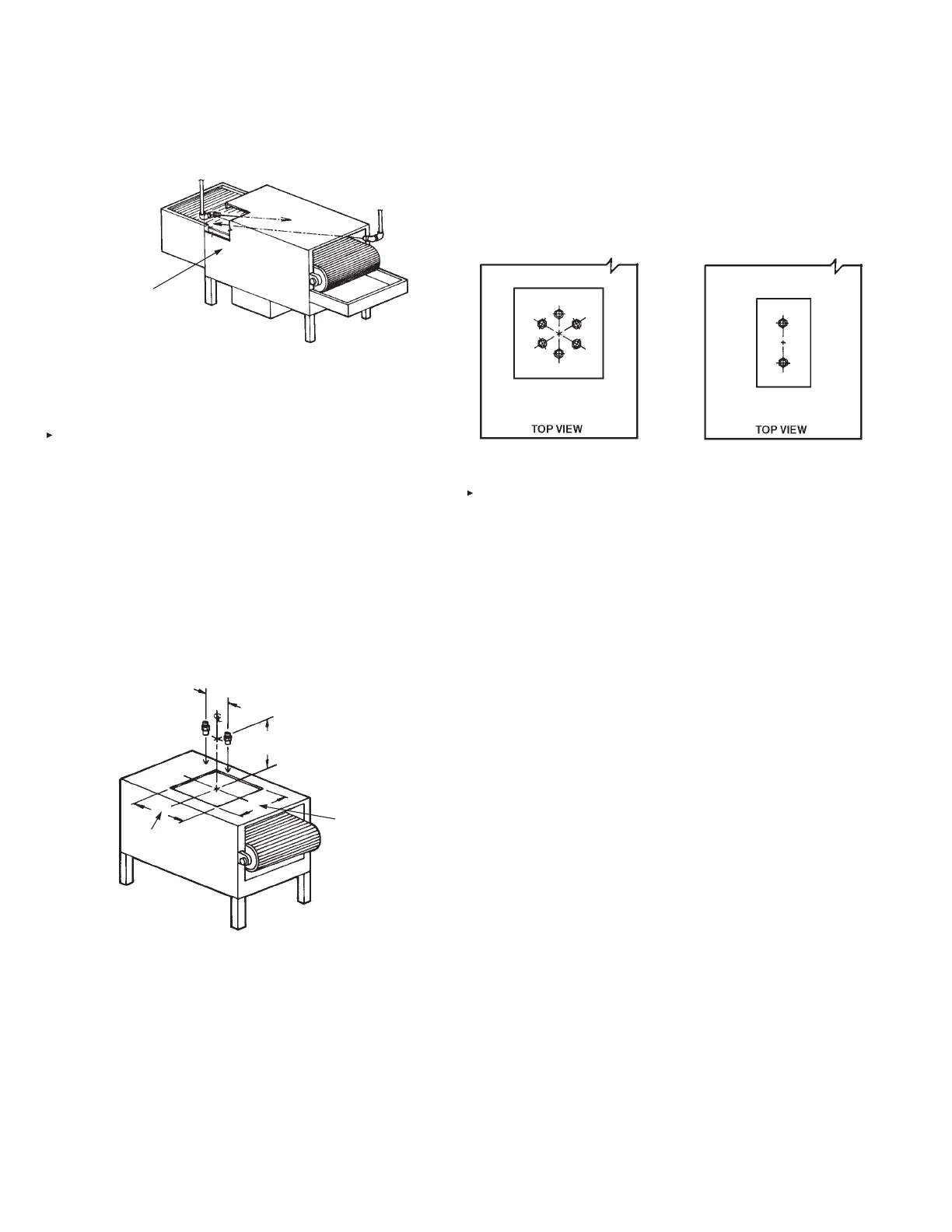

The nozzles may vary in position as long as they are evenly

spaced from the exhaust center and are always 180° opposite

of each other. If the opening is not square, the nozzles must be

positioned along the centerline, parallel to the longest side of the

opening. See Figure 4-56.

FIGURE 4-56

000249

Note: The Metal Blow-off Cap must be used when utilizing

chain broiler protection.

Example No. 1 – Internal broiler size is 24 in. long x 20 in. wide

(609 mm x 508 mm), with an opening of 16 in. x 16 in.

(406 mm x 406 mm).

To determine minimum opening size, multiply the internal

length and the internal width by 0.6:

Length of opening – 24 in. x 0.6 = 14.4 in.

(609 mm x 0.6 = 366 mm)

Width of opening – 20 in. x 0.6 = 12.0 in.

(508 mm x 0.6 = 304 mm)

The minimum allowable opening for overhead protection

would be 14.4 in. x 12.0 in. (365 mm x 304 mm).

This example would be acceptable for overhead protec-

tion.

Example No. 2 – Internal broiler size is 30 in. long x 24 in.

wide (762 x 609 mm) with an opening of 22 in. x 12 in.

(558 x 304 mm).

To determine minimum opening size, multiply internal

length and internal width by 0.6:

Length of opening – 30 in. x 0.6 = 18.0 in.

(762 mm x 0.6 = 457 mm)

Width of opening – 24 in. x 0.6 = 14.4 in.

(609 mm x 0.6 = 365 mm)

Minimum allowable opening for overhead protection

would be 18 in. x 14.4 in. (457 mm x 365 mm).

Because this broiler has an opening of 22 in. x 12 in.

(558 mm x 304 mm), the 12 in. (304 mm) width is below

the minimum allowable calculated dimension of 14.4 in.

(365 mm) and therefore would not be acceptable for

overhead protection.

Salamander Broiler Protection

The R-102 system uses three different nozzle locations for

salamander broiler protection. All of the design options require

a one-ow nozzle.

4-8 IN. (101-203 mm)

10-26 IN.

(254-660 mm)

12 IN. (305 mm)

MINIMUM

12 IN. (305 mm)

MINIMUM

MAXIMUM INTERNAL

BROILER SIZE

32 X 34 IN.

(812 x 863 mm)

SECTION 4 – SYSTEM DESIGN

UL EX3470 ULC EX3470

PAGE 4-22 REV. 11 2014-SEP-01

R-102 Restaurant Fire Suppression Manual

MAXIMUM INTERNAL

BROILER SIZE 43 X 31 IN.

(1092 X 787 mm)

Loading...

Loading...