SPECIFIC APPLICATION BY MODEL (Continued)

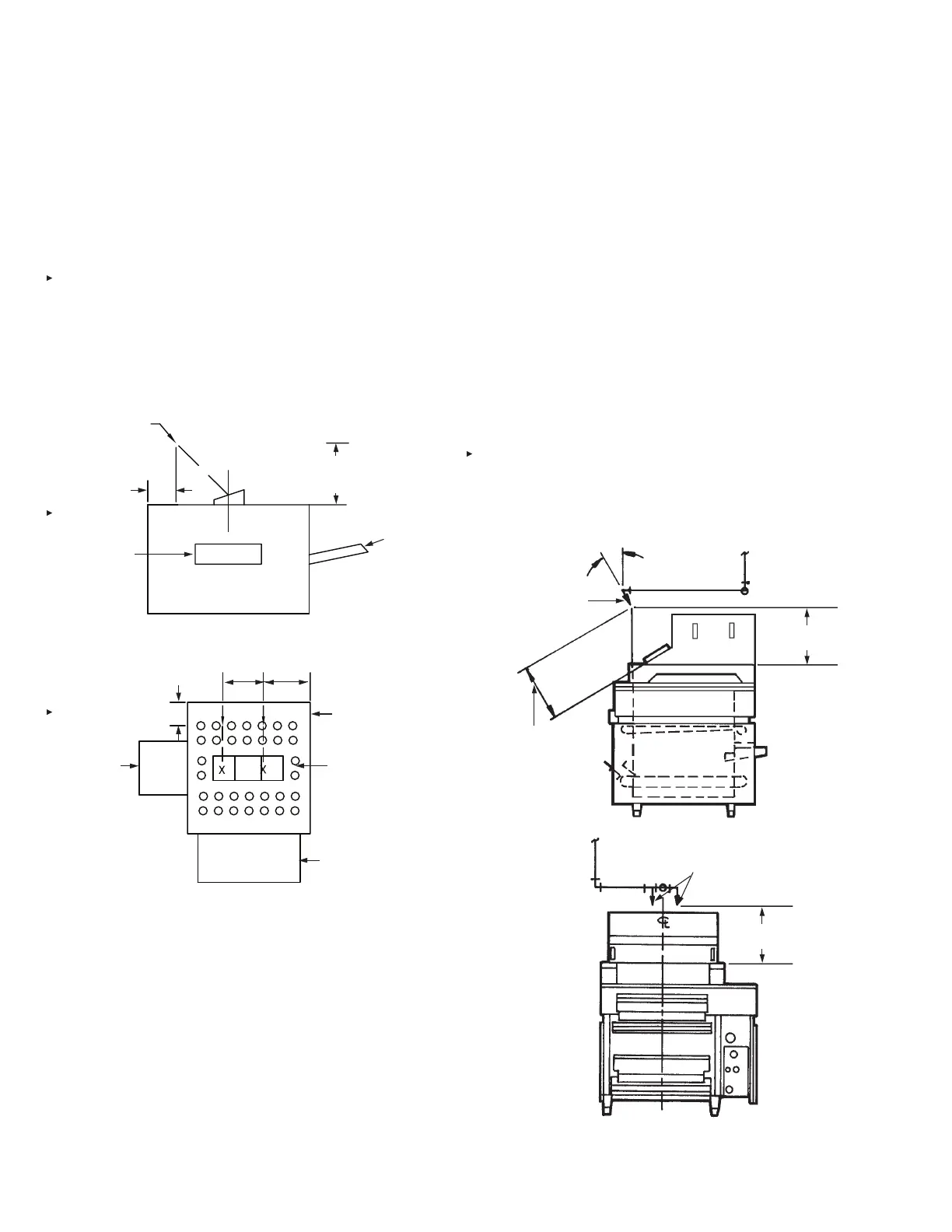

DUKE Electric Broiler – Model FBB – Low Proximity

DUKE Electric Broiler with or without Catalyst View

Nozzle Quantity/Type: Two 245 nozzles

Nozzle Height: 8 in. (203 mm) to 15 in. (381 mm)

Nozzle Location:

6.5 in. (165 mm) from edge of appliance that

impedance plate is angled toward

First nozzle positioned 17.5 in. (444 mm)

from right side of broiler (facing broiler)

Second nozzle positioned 15 in. (381 mm)

from rst nozzle

See Figure 4-87

Nozzle Aiming Point: Aimed at center of opening

FIGURE 4-87

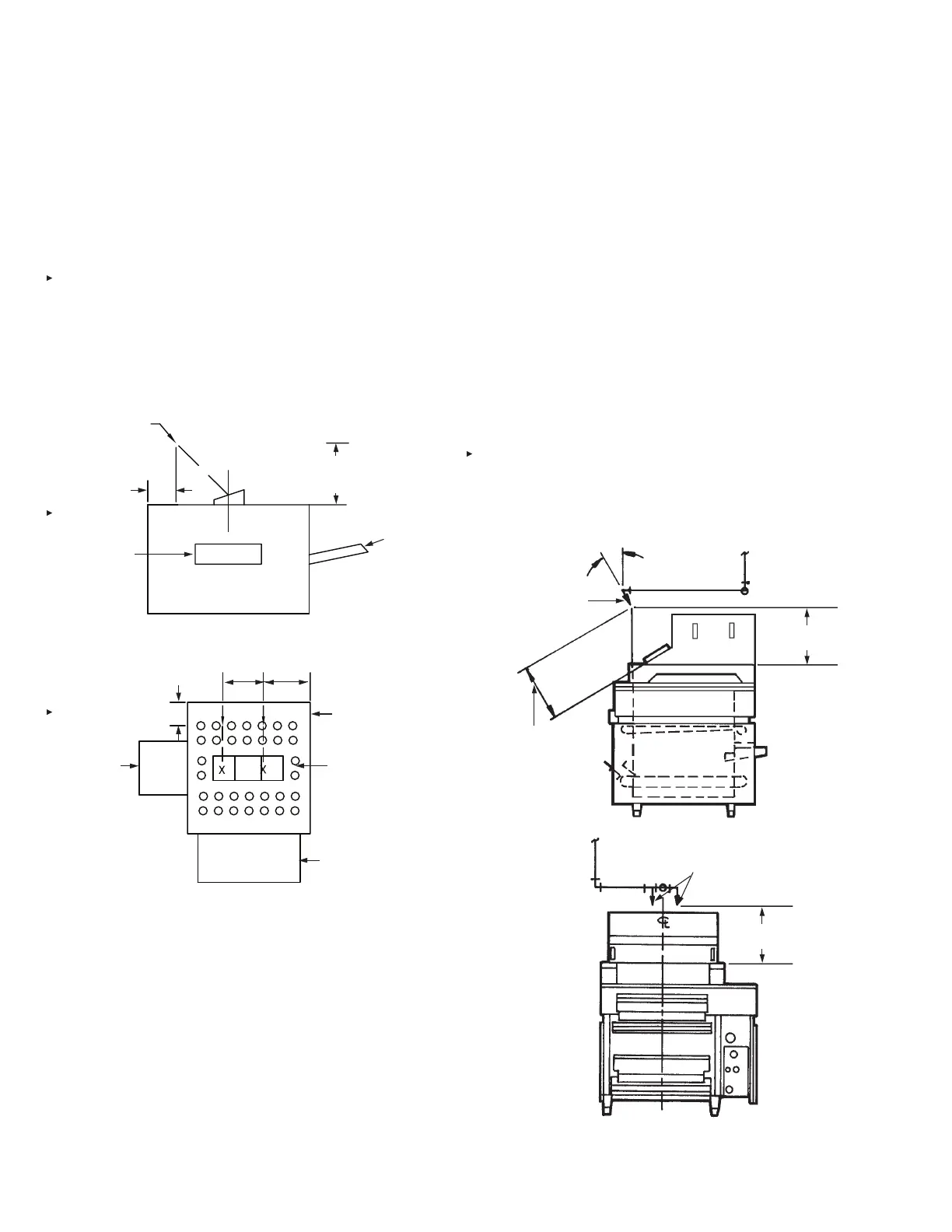

Nieco Broiler Model 940, 962 or 960 With Catalytic

Converter Protection

Note: Nieco broilers without catalytic converters use standard

chain broiler protection options.

Certain models of the Nieco broiler (Models 940, 962, and 960)

are equipped with a catalytic converter to comply with new clean

air laws. Because of the converter, it is necessary to protect

these broilers in a special way. The guidelines for protecting

these broilers are as follows:

– The maximum internal broiling area is 29 in. x 23.5 in.

(737 mm x 596 mm).

– An R-102 3-gallon system with a maximum of six ow

numbers, must be used for protection of each broiler, includ-

ing plenum and duct.

– Each individual broiler must be protected with a minimum of

two 1N nozzles. The nozzles must be located as shown in

Figure 4-88.

– The broiler must be tted with two 1 in. (25 mm) high agent

barriers on the angled surface of the broiler. If these have

not been completed by the equipment supplier, they must be

added in the eld.

FIGURE 4-88

008365

PRODUCT

INPUT

PRODUCT

OUTPUT

FRONT

BACK

SIDE VIEW

(2) – 245 NOZZLE

6 1/2 IN. (165 mm)

FROM EDGE OF

APPLIANCE THAT

IMPEDANCE

PLATE IS ANGLED

TOWARD

8 IN. (203 mm) TO

15 IN. (381 mm)

NOZZLE HEIGHT

PRODUCT

INPUT

PERFORATED

GRILL

CENTER

DUCT

PRODUCT

OUTPUT

TOP VIEW

6 1/2 IN. (165 mm) FROM

EDGE OF APPLIANCE

THAT IMPEDANCE PLATE

IS ANGLED TOWARD

(SEE SIDE VIEW)

008368

15 IN.

(381 mm)

17 1/2 IN.

(444 mm)

000250

(2) 1N NOZZLES

12 IN. TO 13 IN.

(305 mm to 330 mm)

30°

14.25 ± 1 IN.

(362 mm ± 25 mm)

LOCATE NOZZLES 2 13/16 IN. (71 mm) ON

EACH SIDE OF BROILER CENTER LINE

14.25 ± 1 IN.

(362 mm ± 25 mm)

000774

SECTION 4 – SYSTEM DESIGN

UL EX3470 ULC EX3470

PAGE 4-44 REV. 11 2014-SEP-01

R-102 Restaurant Fire Suppression Manual

Loading...

Loading...