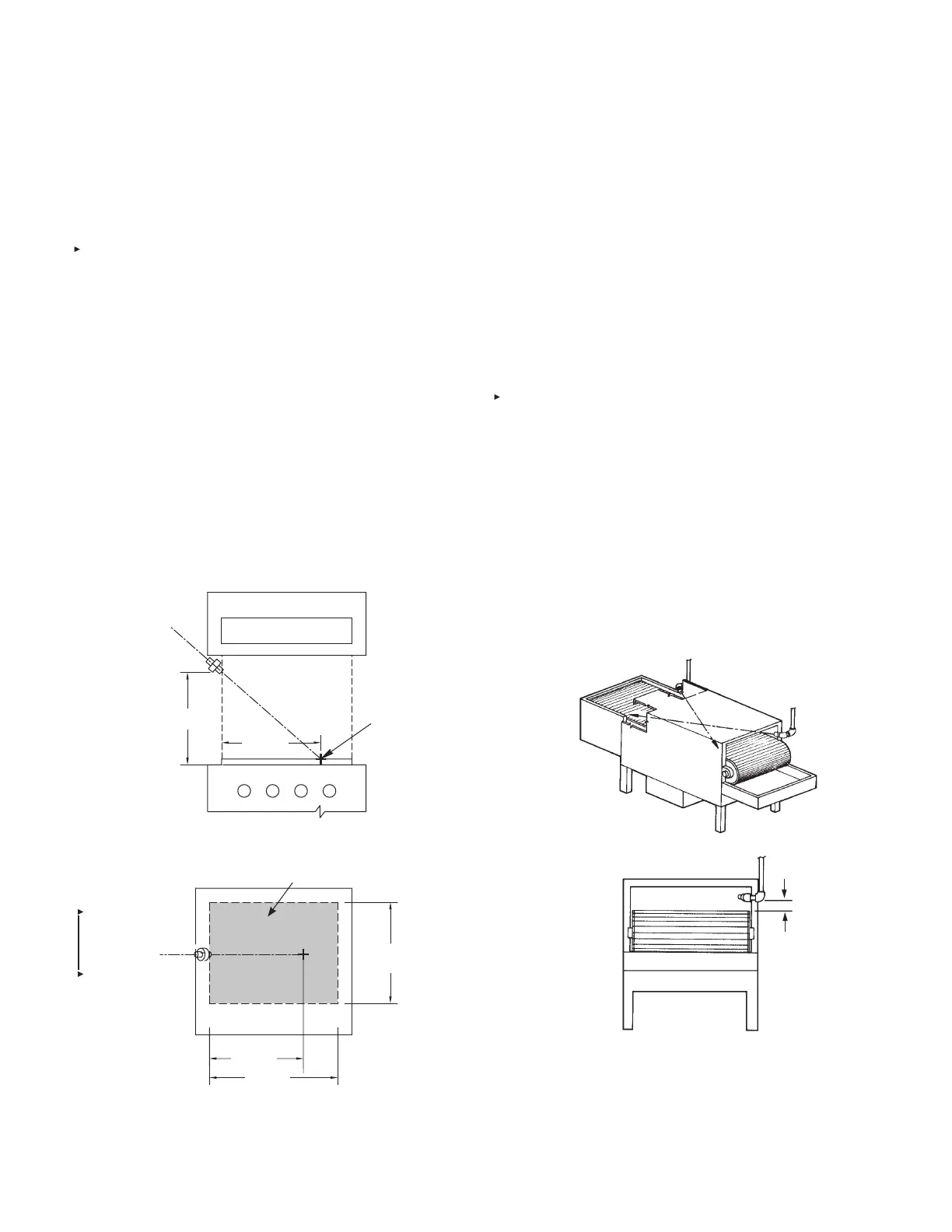

Griddle Protection 1W (1-Flow) Nozzle – Low Proximity

Application

15 in. to 20 in. (381 mm to 508 mm) above the cooking surface.

The low proximity 1-ow nozzle application for the protection of

griddles requires the 1W nozzle.

The nozzle is stamped with 1W indicating that this is a one-ow

nozzle and must be counted as one ow number.

When using the 1W nozzle for low proximity griddle protection

with our without obstruction, the maximum length of the cooking

surface to be protected must not exceed 26 in. (660 mm). The

nozzle must be centered at one end of the maximum 26 in.

(660 mm) length, aimed along a centerline to a point 20 in. (508

mm) from the end of the length, protecting a maximum width of

20.5 in. (520 mm).

The 1W nozzle tip must be positioned at or below the obstruc-

tion, if present. The protected area begins at the point straight

down from the nozzle tip. The nozzle can be positioned above

the edge of the hazard area to be protected. See Figure 4-51

and 4-52.

Note: If the hazard area exceeds the single nozzle coverage

listed above, additional nozzles will be required. The additional

nozzle can be positioned in front at high proximity or at the side

at low proximity.

FIGURE 4-51

FIGURE 4-52

Chain Broiler Protection

The following listed protection guidelines can be applied to any

manufacturer’s chain broilers, if the chain broiler meets the

specied parameters. Chain broilers utilizing catalytic converters

can be protected from overhead using model specic protec-

tion identied in the “Specic Application by Model” section in

System Design. Or, they can be protected with standard 1N

nozzle horizontal chain broiler protection with the nozzles posi-

tioned at either end of the chain broiler openings. Refer to the

“Horizontal Chain Broiler Protection” section for specic design

information.

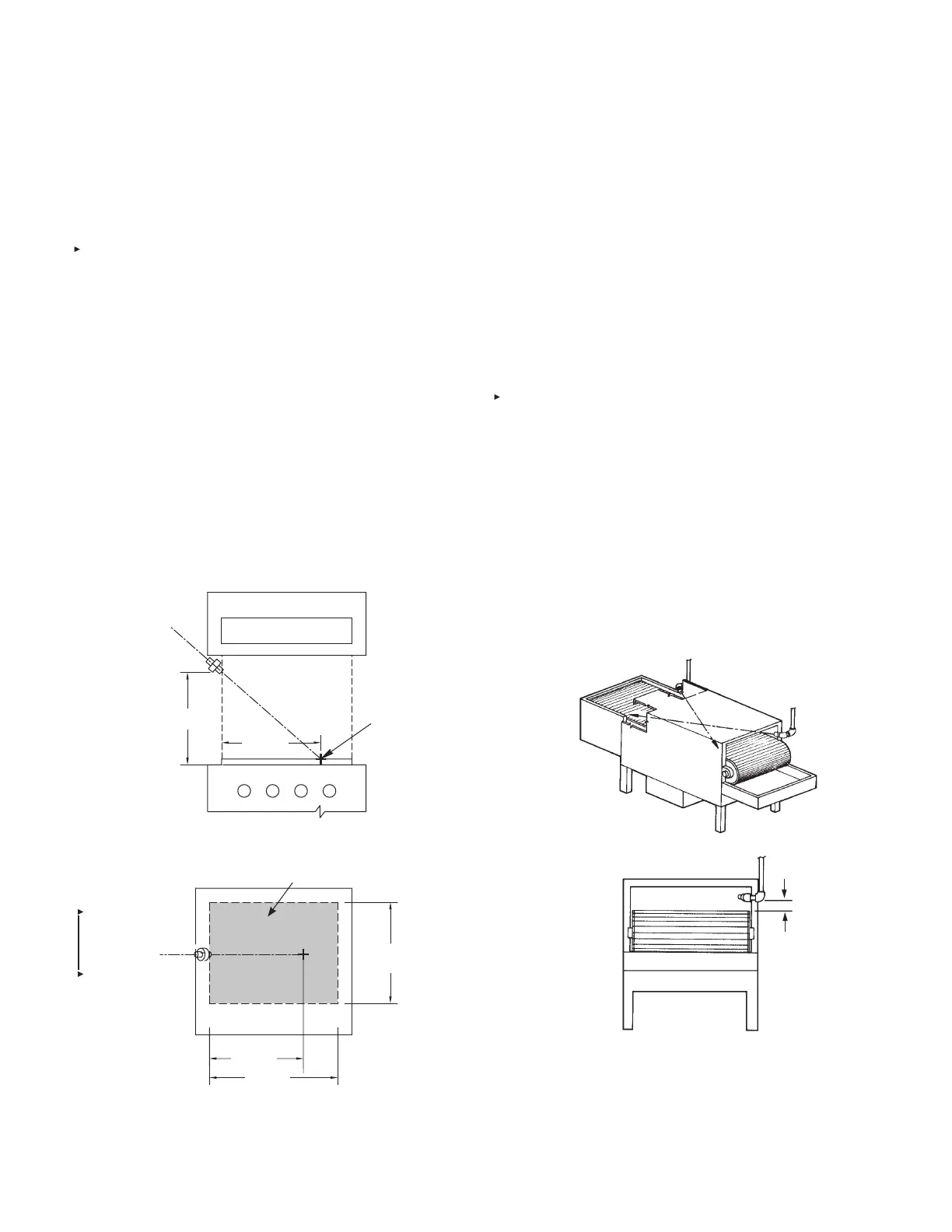

Horizontal Chain Broiler Protection

The R-102 system can use two 1N nozzles for horizontal chain

broiler protection. The nozzle is stamped 1N, indicating that

this is a one-ow nozzle and must be counted as one ow

number (total of two ow numbers for each chain broiler being

protected).

Two 1N nozzles are always needed for chain broiler protec-

tion when the hazard area to be protected does not meet the

“Overhead Broiler Protection” requirements. The maximum

internal size of the broiler is 43 x 31 in. (1092 mm x 787 mm).

The nozzles must be positioned at each end of the enclosed

cooking chamber 1 to 3 in. (25 mm to 76 mm) above the surface

of the chain and a maximum distance of 4 in. (101 mm) away

from the broiler opening. The nozzles may be mounted at either

corner as long as they are at opposite ends of the chain broiler

and positioned to discharge diagonally across the top of the

chain. See Figure 4-53 and 4-54.

000245

FIGURE 4-53

15 – 20 IN.

(381 – 508 mm)

20 IN.

(508 mm)

007924

AIM

POINT

26 IN.

(660 mm)

20 IN.

(508 mm)

20.5 IN.

(520 mm)

007926

AIM POINT

PROTECTED AREA

1 – 3 IN.

(25 – 76 mm)

000246

SECTION 4 – SYSTEM DESIGN

UL EX3470 ULC EX3470

2014-SEP-01 REV. 11 PAGE 4-21

R-102 Restaurant Fire Suppression Manual

Loading...

Loading...