SECTION 5 – INSTALLATION INSTRUCTIONS

UL EX3470 ULC EX3470

PAGE 5-28 REV. 11 2014-SEP-01

R-102 Restaurant Fire Suppression Manual

INSTALLATION OF REMOTE MANUAL PULL STATION OR

MECHANICAL GAS VALVE UTILIZING FLEXIBLE CONDUIT

(Continued)

Connecting the Block and the Faceplate (Continued)

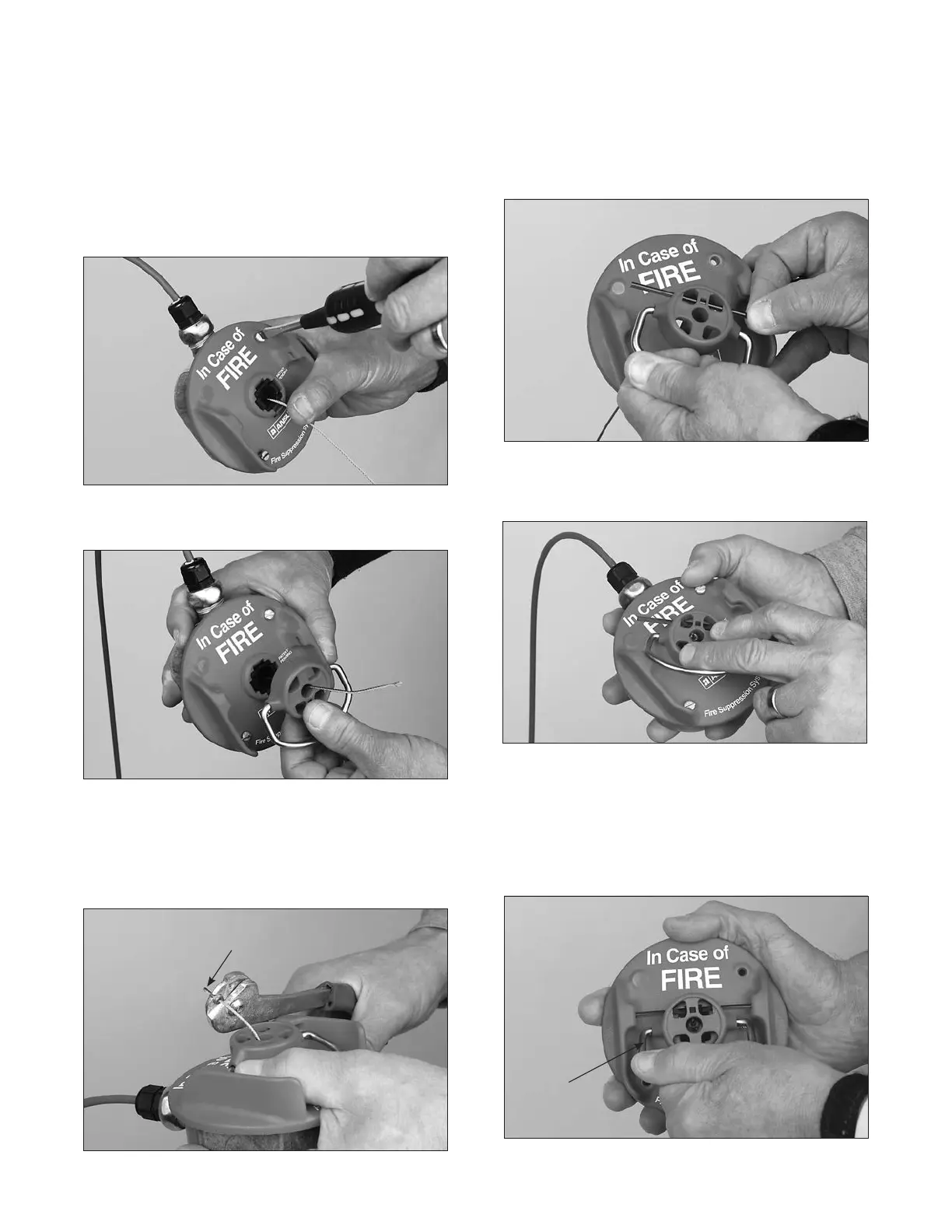

3. Place the faceplate over the top of the electrical box and insert

the two screws to secure the faceplate. See Figure 5-79.

FIGURE 5-79

008012

4. Thread the wire rope through the pull knob. See Figure 5-80.

FIGURE 5-80

008013

5. Thread the wire rope through stop sleeve and leave approxi-

mately 1/4-3/8 in. (6.4-9.5 mm) extended past sleeve. Crimp

stop sleeve twice using Crimping tool, National Telephone

Supply Co. Nicopress Sleeve Tool (Stock No. 51-C-887).

Verify stop sleeve is secure on wire rope. See Figure 5-81.

LEAVE 1/4-3/8 IN.

(6-9 mm)

FIGURE 5-81

008014

6. Insert the break rod into the two holes toward the top of the

pull knob. See Figure 5-82.

FIGURE 5-82

008015

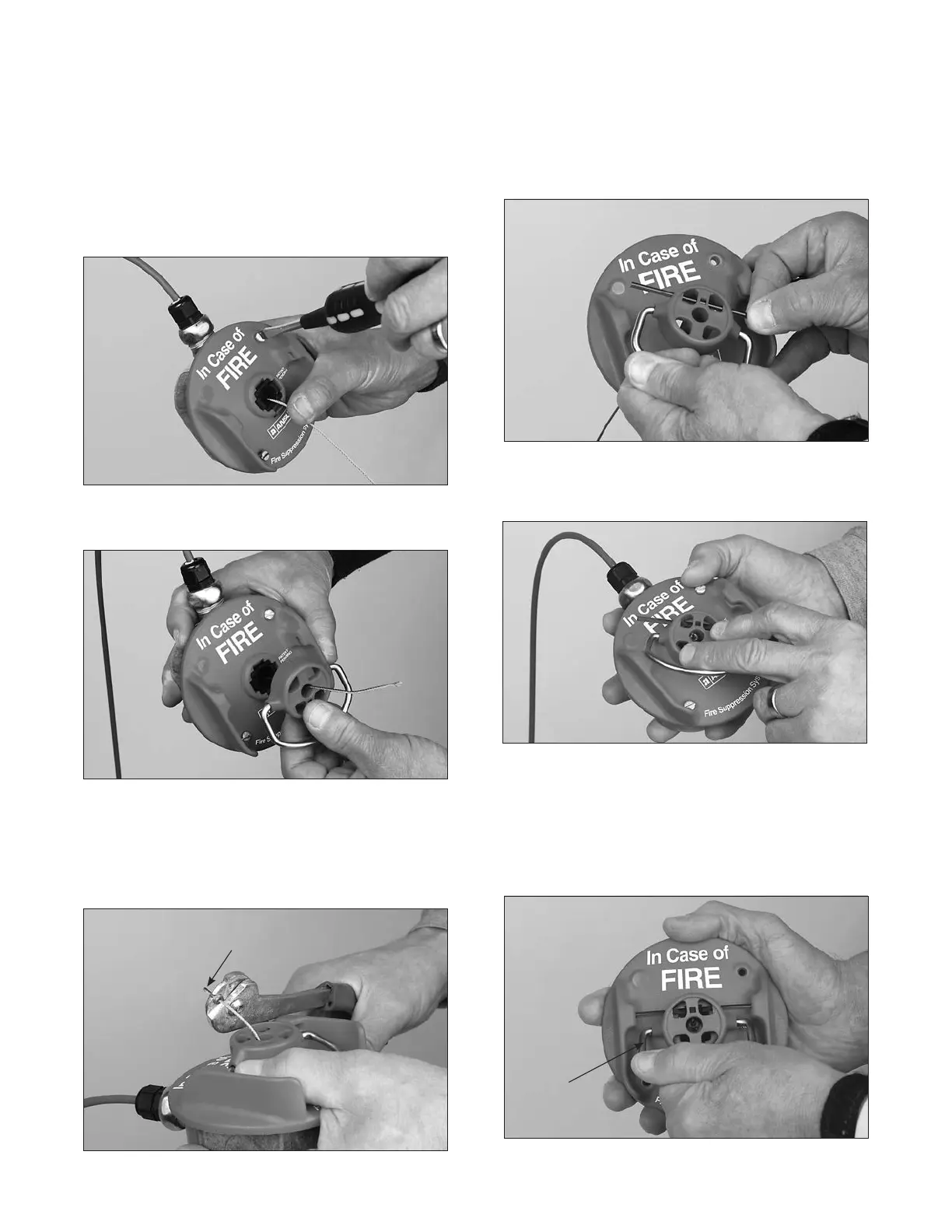

7. Pull the excess slack back to the AUTOMAN release. This

will pull the pull knob assembly in place. See Figure 5-83.

FIGURE 5-83

008016

8. Hold the pull knob assembly against the faceplate. Rotate

the pull knob assembly counterclockwise until the break rod

and pull knob snap in place. See Figure 5-84.

Note: Take care in snapping in the ends of the break rod

into the pull station side shields while rotating the entire

assembly.

ROTATE

COUNTER-

CLOCKWISE

FIGURE 5-84

008017

Loading...

Loading...