SECTION 8 – MAINTENANCE EXAMINATION

UL EX3470 ULC EX3470

PAGE 8-2 REV. 11 2014-SEP-01

R-102 Restaurant Fire Suppression Manual

SEMI-ANNUAL MAINTENANCE EXAMINATION (Continued)

Alternate Test Method:

The actuation line can also be pressurized with either CO

2

or N

2

from a cartridge or with dry air, CO

2

, or N

2

from a

larger cylinder.

a. Cock the AUTOMAN regulated release assembly and

carefully insert lock bar (Part No. 14985) or lock pin (Part

No. 438031). See Figure 8-9 or Figure 8-10.

b. Make certain expellant gas line hose and/or pipe from

the regulator in the AUTOMAN regulated release is

disconnected from agent storage tanks.

c. Connect Regulator Test Kit (Part No. 56972) to one

of the expellant gas line hoses and securely cap the

remaining hose or pipe. See Figure 8-12.

d. Verify that no cartridges are installed in the AUTOMAN

or the regulated actuator assembly(s).

e. To verify operation of the regulated actuator assem-

bly(s), Pressure Adaptor (Part No. 427560) can be used

to connect to a pressurized CO

2

or N

2

cylinder, instead

of using a CO

2

or N

2

cartridge.

Note: The pressure adaptor assembly comes with a 1/4 in.

NPT pipe plug that is required to be installed in the side of

the adaptor.

f. Install a suitable 1/4 inch air pressure quick connect

fitting (supplied by others) to the bottom of the adaptor.

g. Install and hand tighten the adaptor to the cartridge

receiver and securely attach the corresponding connec-

tor from the gas cylinder hose assembly.

h. With the valve on the regulator test kit closed, remove

the lock bar or lock pin and operate the remote cable

operated pull station to operate the regulated release.

i. Open the pressure cylinder valve to verify that the regu-

lated actuator assembly(s) has operated properly and the

air cylinder has unlatched the ANSUL mechanical gas

valve, if used.

j. Once regulated actuator and gas valve operation is veri-

fied, close the valve on the pressurized cylinder, if used,

and open the valve on the regulator test kit to relieve any

residual pressure.

Note: Although only required at 12 year intervals, the

regulator in the AUTOMAN regulated release can also be

verified. See Maintenance steps on page 8-6.

k. Re-cock the AUTOMAN regulated release and remove

the spent cartridge or pressure adaptor from the cartridge

receiver.

l. If there were leaks in the actuation line or in the 1/8 inch

copper gas tubing for the air cylinder(s), re-tighten the

fittings or replace damaged components.

m. If the cartridge puncture pin in the regulated actuator(s)

did not fully extend, dismantle the actuator and inspect

components of the actuator assembly.

• Oncethepneumaticactuatorisdisassembled,remove

the actuator piston assembly and check the interior

walls of the actuator body for signs of damage or corro-

sion.

• Check the o-ring for elasticity or cuts. Replace, if

necessary. Clean and coat o-ring with a good grade of

extreme temperature silicone grease and reinstall.

• Re-assemble the actuator assembly(s), and reconnect

all actuation and all expellant piping or hose.

6. Remove gasket from cartridge receiver in regulated release

mechanism and each regulated actuator. Check gasket for

elasticity or cuts and replace Gasket (Part No. 181) if neces-

sary. Clean and coat gasket lightly with a good grade of

extreme temperature grease. Reinstall gasket into cartridge

receiver(s).

7. From tank in regulated release assembly: Disconnect the

expellant gas hose from each tank adaptor assembly.

From tank in bracket/enclosure assembly: Disconnect the

expellant gas piping union at each tank adaptor inlet line.

8. Disconnect distribution piping union at each tank adaptor

outlet line.

9. From tank in enclosure: Remove tank. Keep in upright posi-

tion to avoid spilling the agent.

From tank in bracket assembly: Loosen wingnut, disengage

bracket band, and remove each tank. Keep tank in upright

position to avoid spilling the agent.

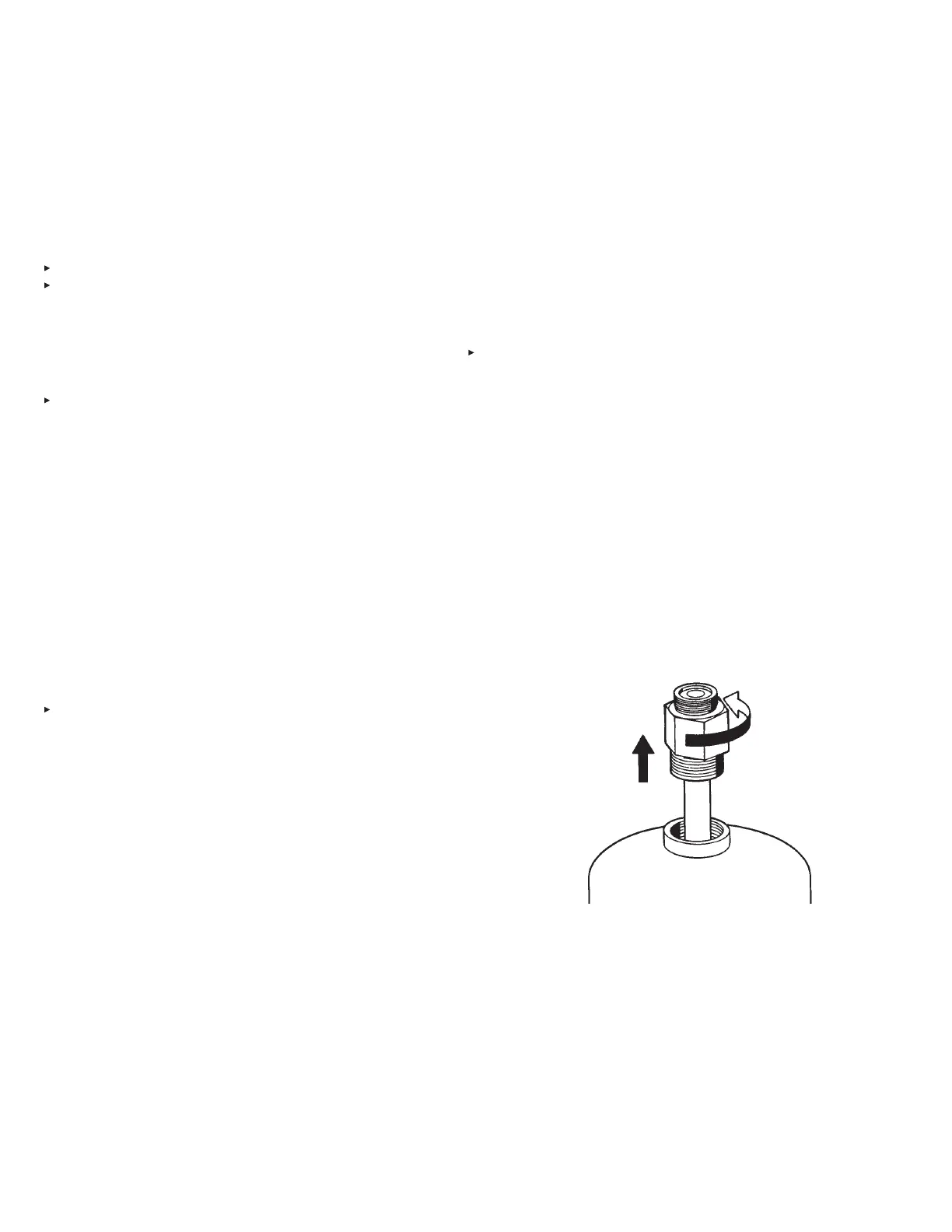

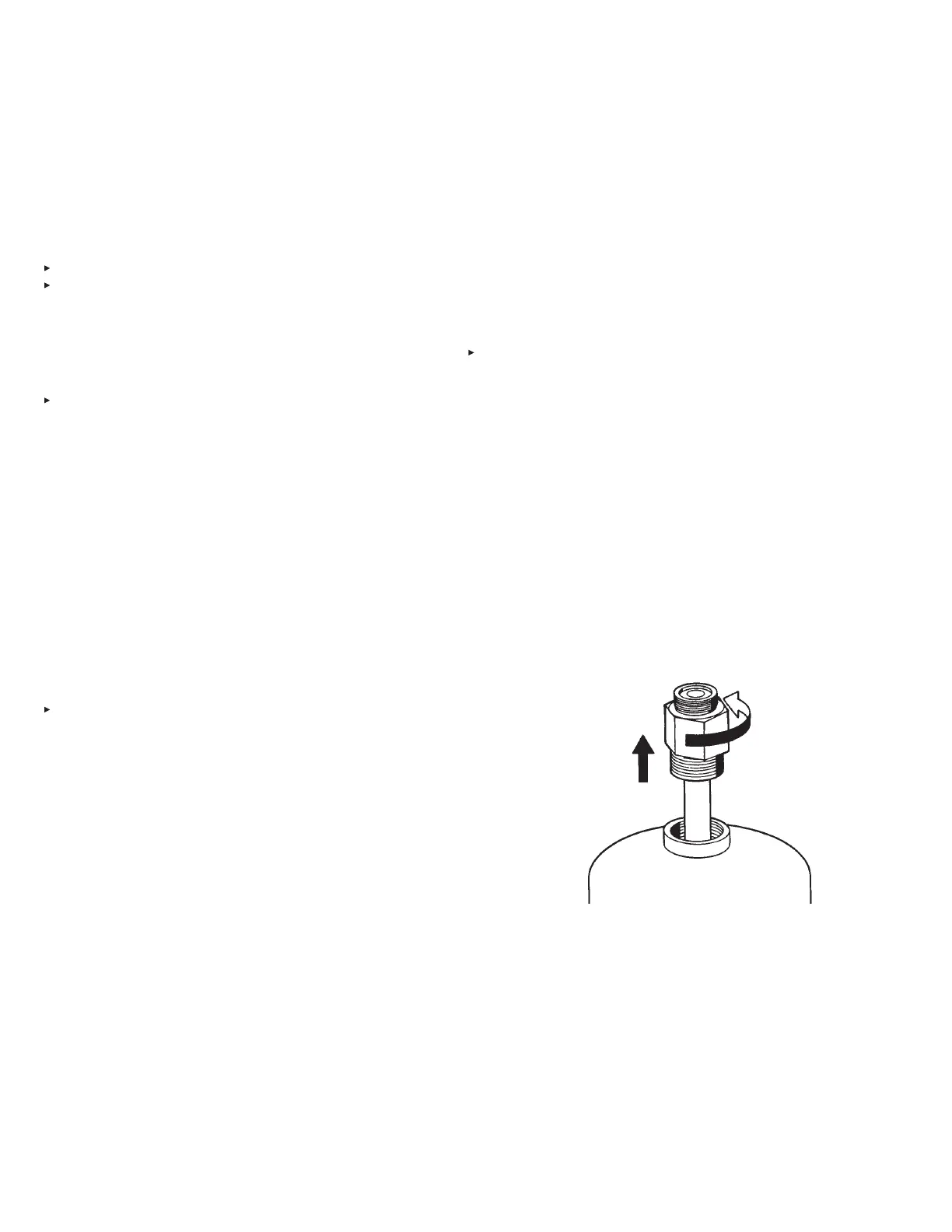

10. Remove tank adaptor/tube assembly from each tank. See

Figure 8-3.

FIGURE 8-3

000291

11. Make certain that each tank is filled with 1.5 (5.8 L) or 3.0

(11.6 L) gallons of only ANSULEX Low pH Liquid Fire

Suppressant. Fill level to be ONLY to the level indicated

in the “Installation” section. See Page 5-3, Figure 5-6, for

detailed filling tolerances.

Loading...

Loading...