SECTION 8 – MAINTENANCE EXAMINATION

UL EX3470 ULC EX3470

PAGE 8-4 REV. 11 2014-SEP-01

R-102 Restaurant Fire Suppression Manual

SEMI-ANNUAL MAINTENANCE EXAMINATION (Continued)

Alternate Test Method: (Continued)

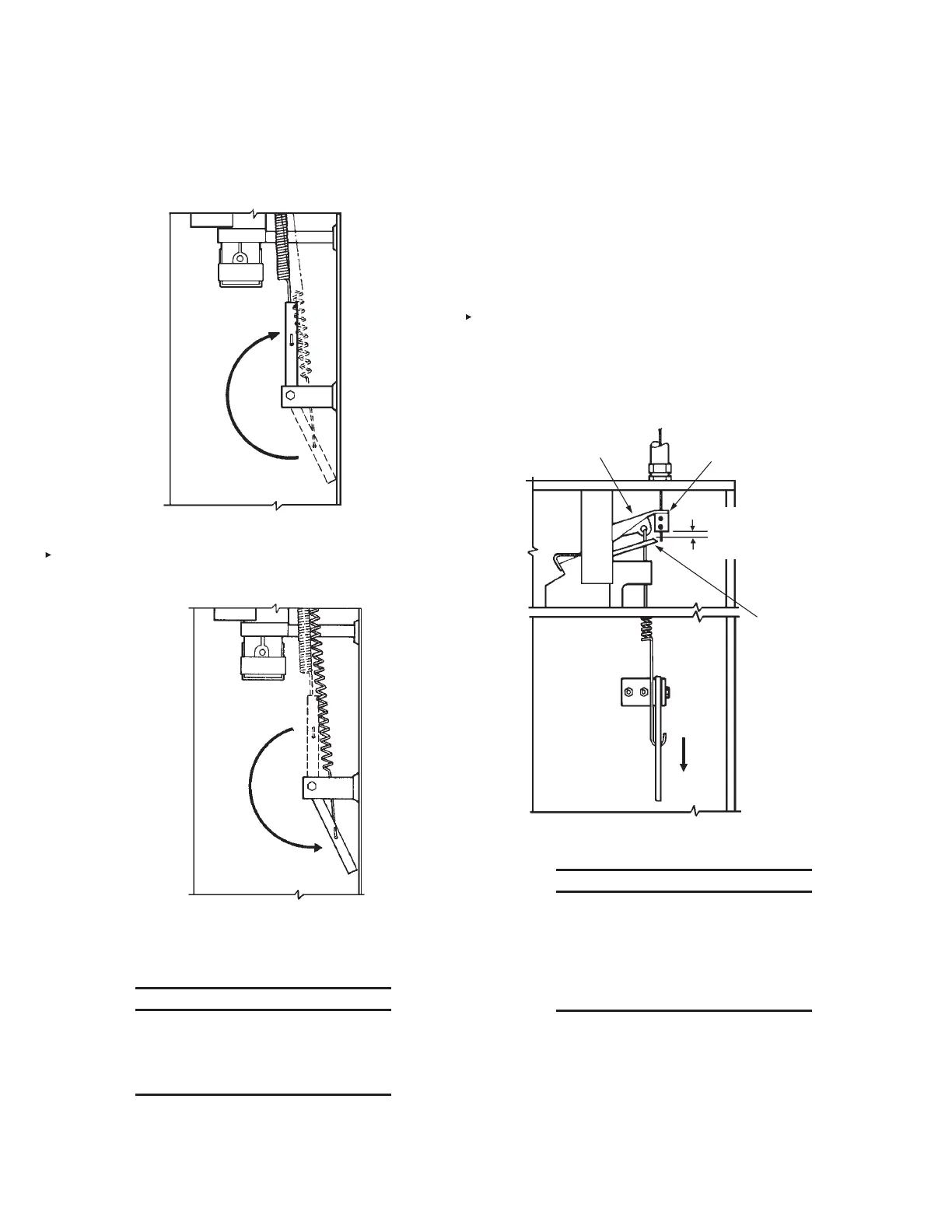

19. Raise tension lever to “UP” position. See Figure 8-6.

TENSION LEVER

IN “UP” POSITION

FIGURE 8-6

000322

20. Install test link (Part No. 24916) in terminal detector.

21. Lower tension lever to “DOWN” position. See Figure 8-7.

TENSION LEVER

IN “DOWN” POSITION

FIGURE 8-7

001096

22. Using wire cutter, cut test link at terminal detector to simu-

late automatic actuation.

NOTICE

If regulated release mechanism does not

actuate, refer to Steps 2 and 3 of “Testing

Detection System” in “Testing and Placing

in Service,” Section 6, Page 6-3.

23. After successful actuation, raise the tension lever to “UP”

position.

24. Remove and destroy all existing fusible links from the termi-

nal and series detector brackets and replace with proper-

ly-rated ANSUL approved, fusible links in accordance with

NFPA 17A.

25. Inspect wire rope at all detector locations, pulley elbows,

pulley tee and at AUTOMAN release. If wire rope shows

signs of wear or fraying, replace entire length.

26. Lower the tension lever to “DOWN” position.

27. Recock the regulated release mechanism and insert the

lock bar or lock pin.

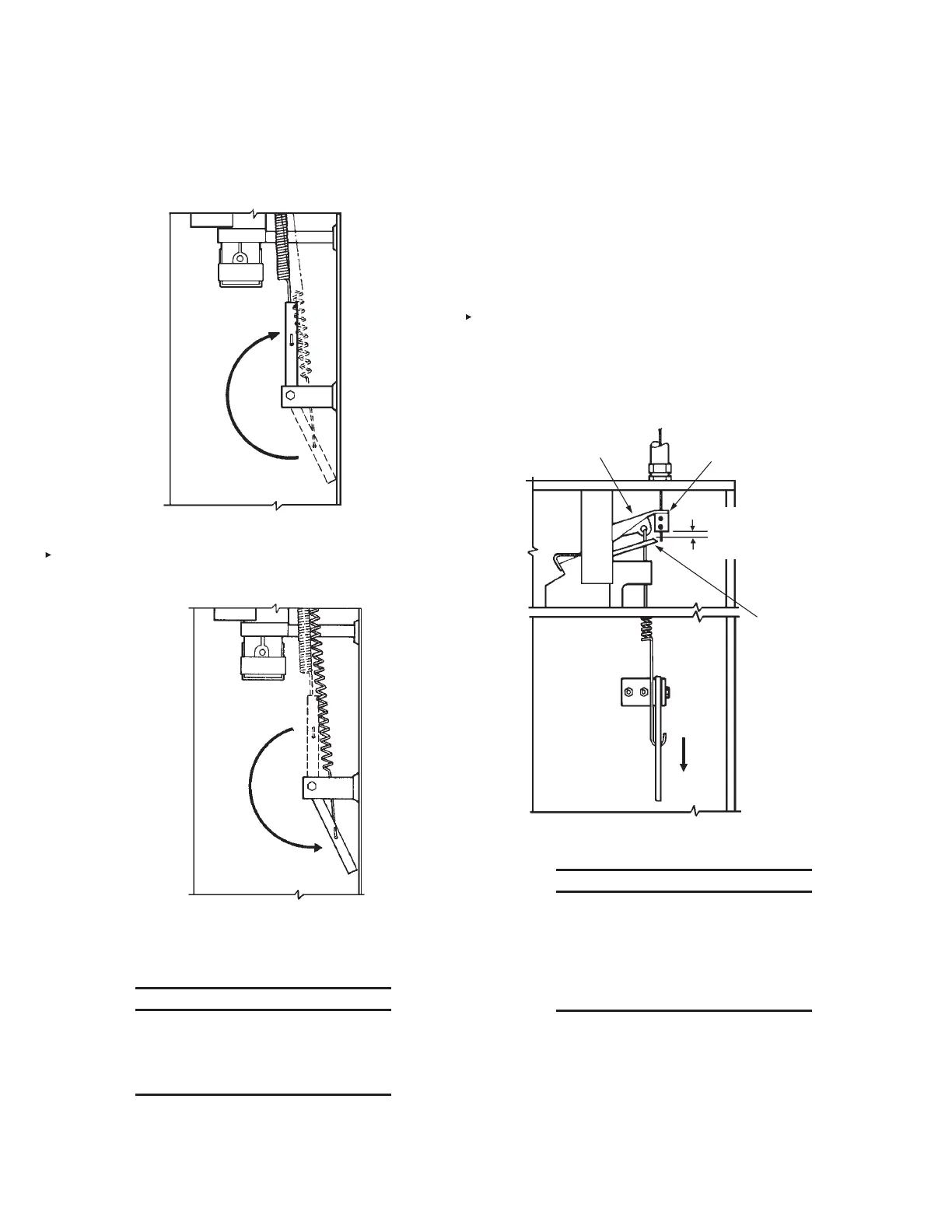

28. Inspect the base of the wire rope locking clamp to make

certain that there is a minimum of 1/4 in. (6.4 mm) and a

maximum of 3/8 in. (9.5 mm) clearance between the base of

the trip hammer locking clamp assembly and the cable lever

assembly. See Figure 8-8.

TRIP HAMMER

ASSEMBLY

CABLE LEVER

ASSEMBLY

LOCKING

CLAMP

1/4 IN. (6.4 mm)

MINIMUM

3/8 IN. (9.5 mm)

MAXIMUM

FIGURE 8-8

000329

NOTICE

If clearance is not between 1/4

in. (6.4 mm) or 3/8 in. (9.5 mm),

raise tension lever to “UP” position,

raise trip hammer 3/8-1/2 in. (9.5-

12.7 mm), tighten set screws, and repeat

Steps 24 and 26.

29. For scissor-style linkage, locate linkage and properly posi-

tion in each bracket all the way toward termination end of

detection run.

30. If a mechanical gas valve is installed, begin the test proce-

dure by removing both side covers.

31. At the regulated release, push the air cylinder rod fully

down.

Loading...

Loading...