SECTION 8 – MAINTENANCE EXAMINATION

UL EX3470 ULC EX3470

PAGE 8-10 REV. 11 2014-SEP-01

R-102 Restaurant Fire Suppression Manual

12-YEAR MAINTENANCE EXAMINATION (Continued)

20. Check all nozzles to ensure that they are free of cooking

grease build-up and have a covering of clean silicone

grease on the orifice. Reinstall blow-off caps.

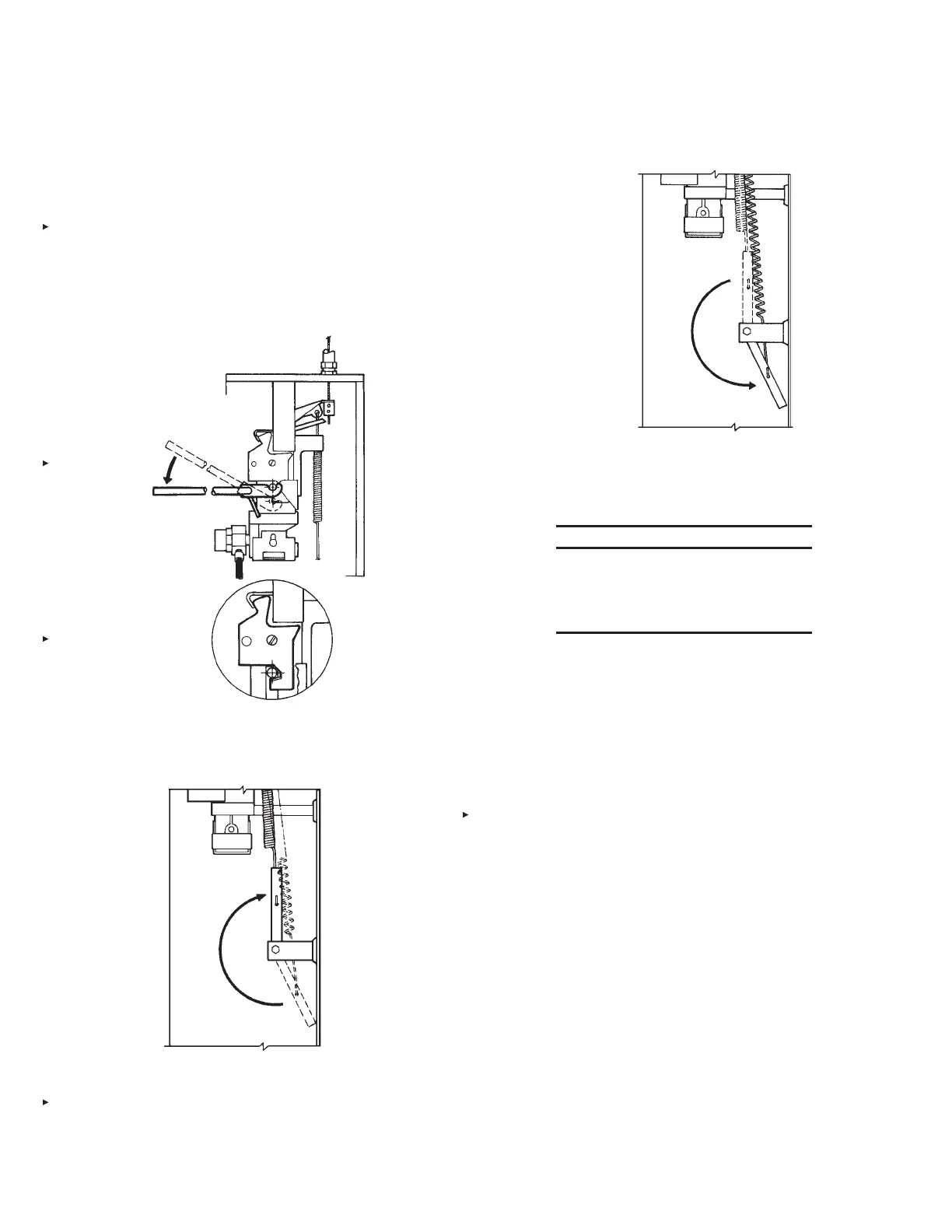

21. Remove lock bar or lock pin and manually test the regulated

release assembly by operating the remote manual pull

station.

22. Cock the regulated release mechanism using cocking lever

(Part No. 14995 or 435603/Part No. 441042 or 441041).

See Figure 8-17.

FIGURE 8-17

009468

23. Raise the tension lever to “UP” position. See Figure 8-18.

TENSION LEVER

IN “UP” POSITION

FIGURE 8-18

000362

24. Install test link (Part No. 24916) in terminal detector.

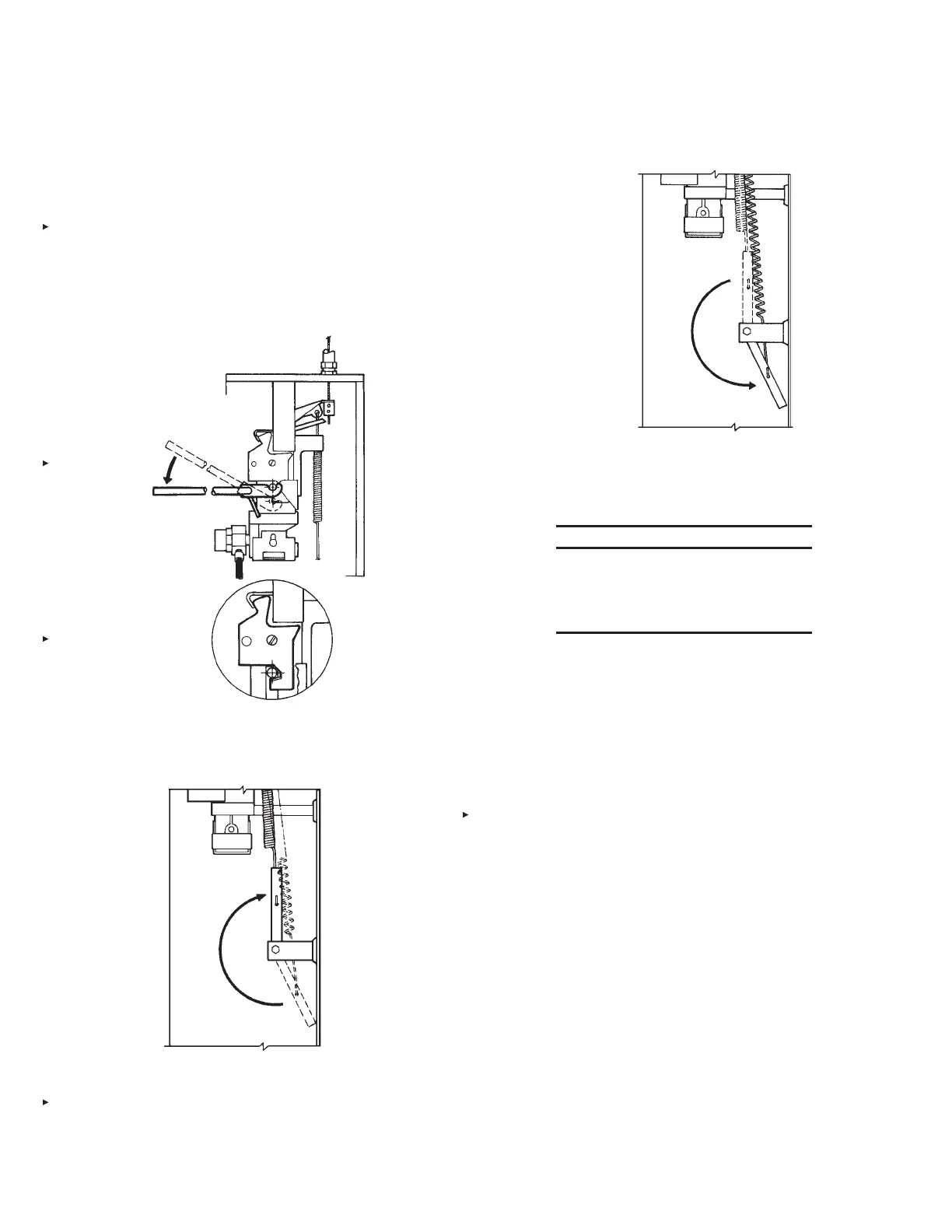

25. Lower tension lever to “DOWN” position. See Figure 8-19.

TENSION LEVER

IN “DOWN” POSITION

FIGURE 8-19

001096

26. Using wire cutter, cut test link at terminal detector to simu-

late automatic actuation.

NOTICE

If regulated release mechanism does not

actuate, refer to Steps 2 and 3 of “Testing

Detection System” in “Testing and Placing

in Service,” Section 6.

27. After successful actuation, raise the tension lever to “UP”

position.

28. Remove and destroy all existing fusible links from the

terminal and series detector brackets and replace with

properly-rated ANSUL approved, fusible links in accordance

with NFPA 17A.

29. Lower tension lever to “DOWN” position.

30. Recock the regulated release mechanism and insert lock

bar or lock pin.

Loading...

Loading...