Maintenance - 50h

4812160101_A.pdf2014-07-04

Tires - Air pressure - Wheel nuts - Tightening

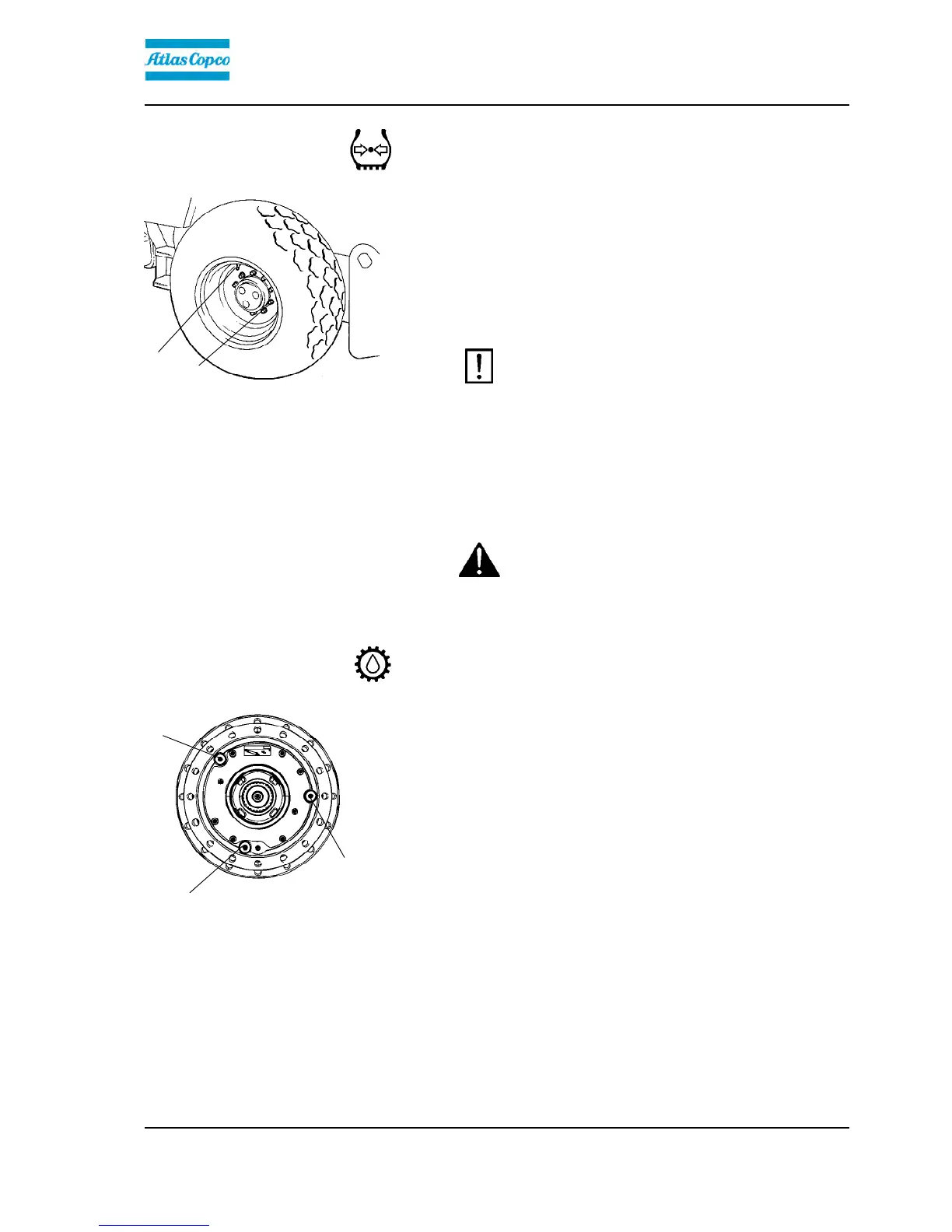

Fig. Wheels

1. Air valve

2. Wheel nut

1

2

Check the tire pressures using a pressure gauge.

If the tires are filled with fluid, the air valve (1) must be

in the "12 o'clock" position during pumping.

Recommended pressure: See Technical

Specifications.

Check the tire pressure.

When changing the tires it is important that both

of them have the same rolling radius. This is

necessary to ensure proper functioning of the

anti-slip in the rear axle.

When changing the tires it is important that both

of them have the same rolling radius. This is

necessary to ensure proper functioning of the

anti-slip in the rear axle.

Check the tightening torque of the wheel nuts (2) at

630 Nm (465 lbf.ft).

Check both wheels and all nuts. (This only applies to a

new machine or newly fitted wheels).

Check the safety manual that accompanies the

roller before filling the tires with air.

Check the safety manual that accompanies the

roller before filling the tires with air.

Drum gearbox - Oil change

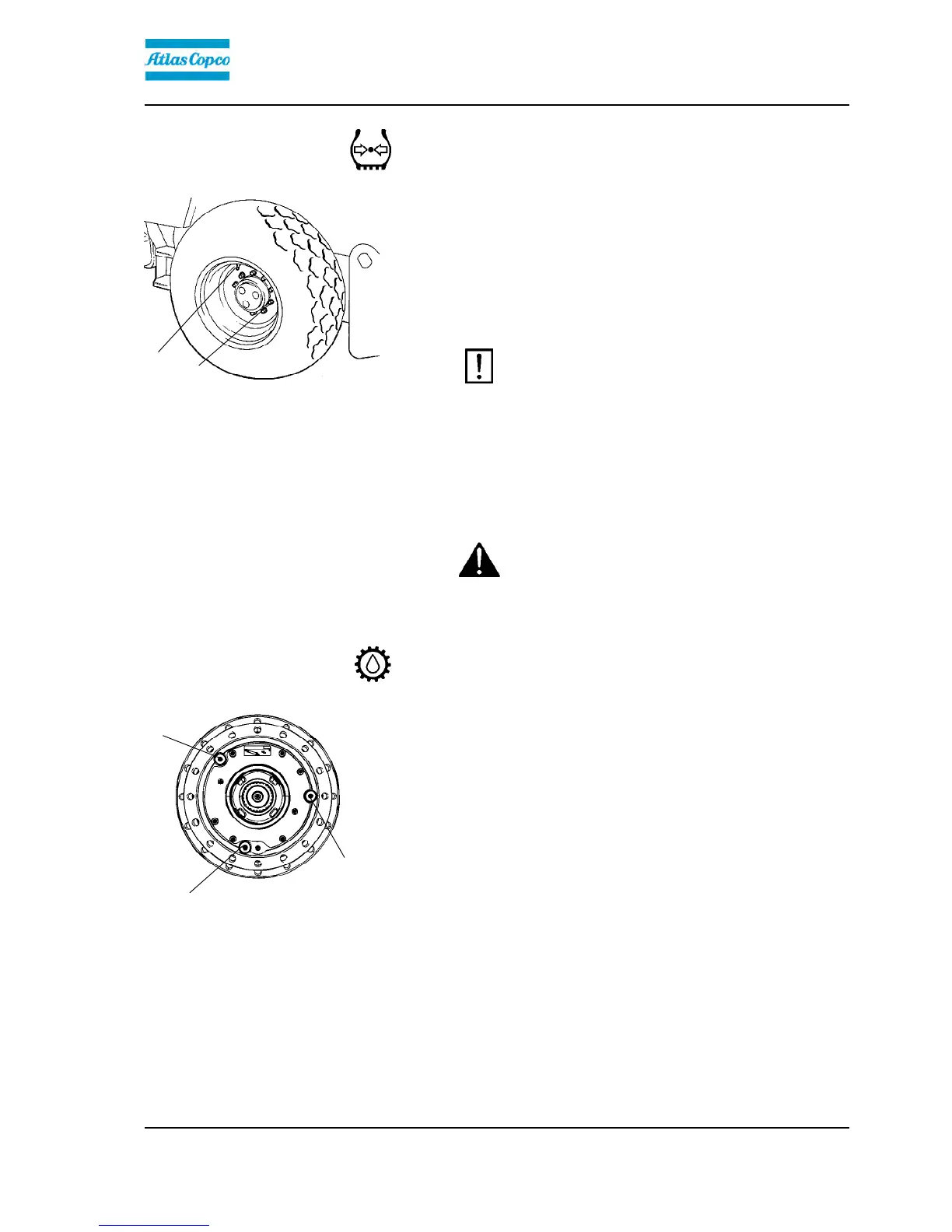

Fig. Drum gearbox

1. Drain plug

2. Filler plug

3. Level plug

1

2

3

Wipe clean, unscrew the plugs (1, 2 and 3) and drain

the oil into a suitable receptacle, capacity about 5.0

liters (5,3 qts.).

Refit the drain plug (1) and fill with oil up to the level

plug (3), according to "Drum gearbox - Checking the

oil level".

Use transmission oil according to the lubricant

specification.

Clean and refit the level plug (3) and filler plug (2).

109

Loading...

Loading...