V5−A/05/14V5−A/05/14

Instruction Manual w VERTICUS 5 Compressor Units

A-16

The current oil list is provided in section

F. Order this list regularly through the

BAUER Technical Service Department.

For operation under difficult conditions such as continuous

running and/or high ambient temperatures we recommend

the use of BAUER high performance compressor oils, only,

according to the oil list. These oils are tested in our com

pressors and have proved excellent quality under ambient

temperatures between +5 C (41 F) and +45 C (113 F).

For lower temperatures, a heating device is required which

is capable of pre-heating the crankcase up to +5 C (41 F).

All our compressor units are delivered ex-

works with lubricating oil N28355.

For operation under less severe conditions we can also re

commend mineral compressor oils which are suitable for

operation under ambient temperatures between +5 C (41

F) and +35 C (95 F). Here also, pre-heating is required for

lower temperatures.

2.2.1. Changing the oil type

To avoid severe damage to the com

pressor unit when changing the oil type,

follow the measures given in section D-2.

3. INTAKE FILTER

3.1. FUNCTIONAL DESCRIPTION

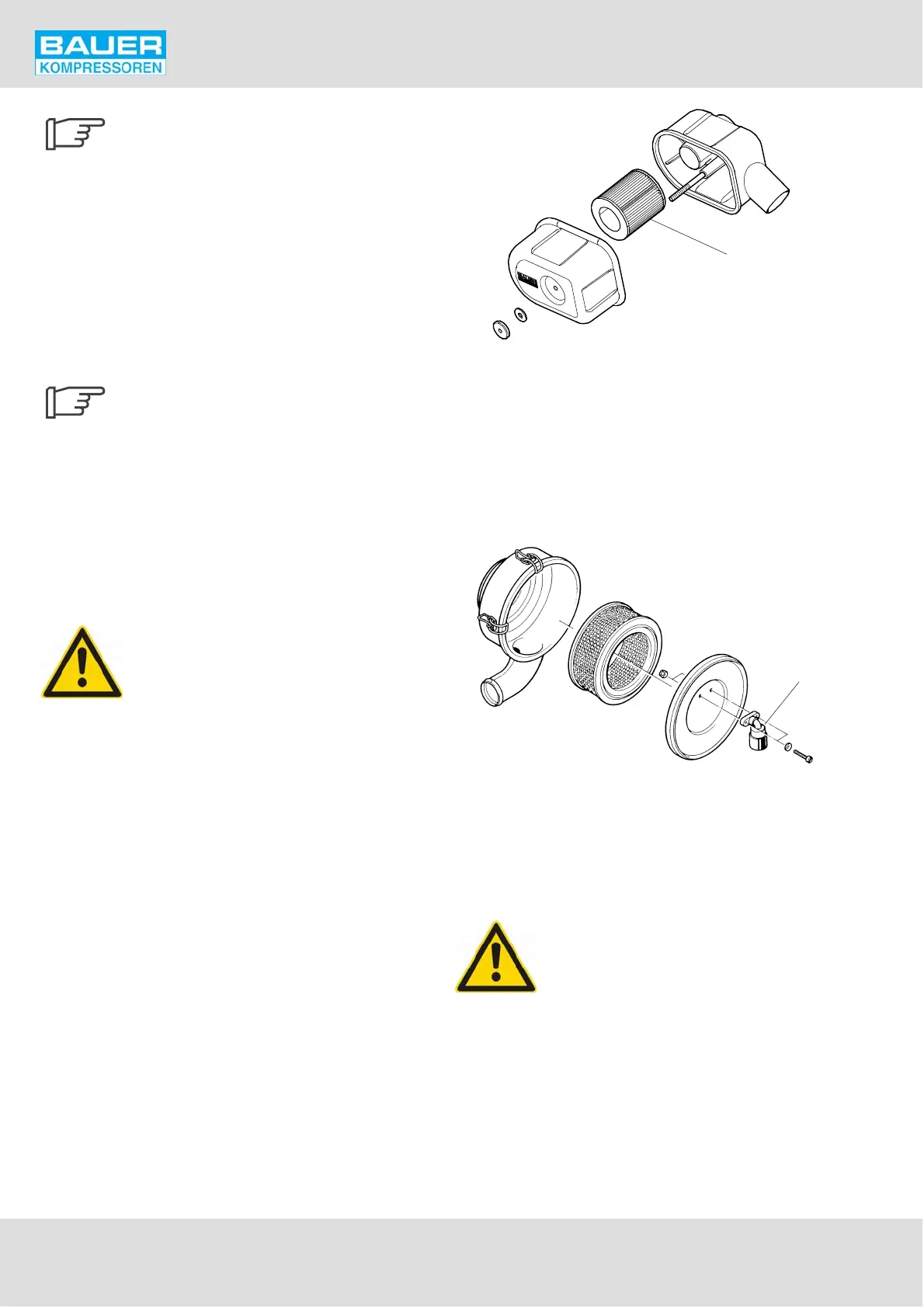

3.1.1. IK12.14

A dry micronic filter is used to filter intake air, see Fig. 14.

It is fitted with a replaceable filter cartridge (1). The intake

pipe is connected to a plastic hose drawing the air from the

cooling air duct.

3.1.2. Intake manifold

As standard, the air is taken in through the cooling air duct

and a plastic hose. Optionally, an intake manifold can be

mounted on top of the unit. This allows the intake air to be

taken from an external source or the surroundings. Refer to

the compressor unit drawing in section F.

Fig. 14 Intake filter, IK12.14

1

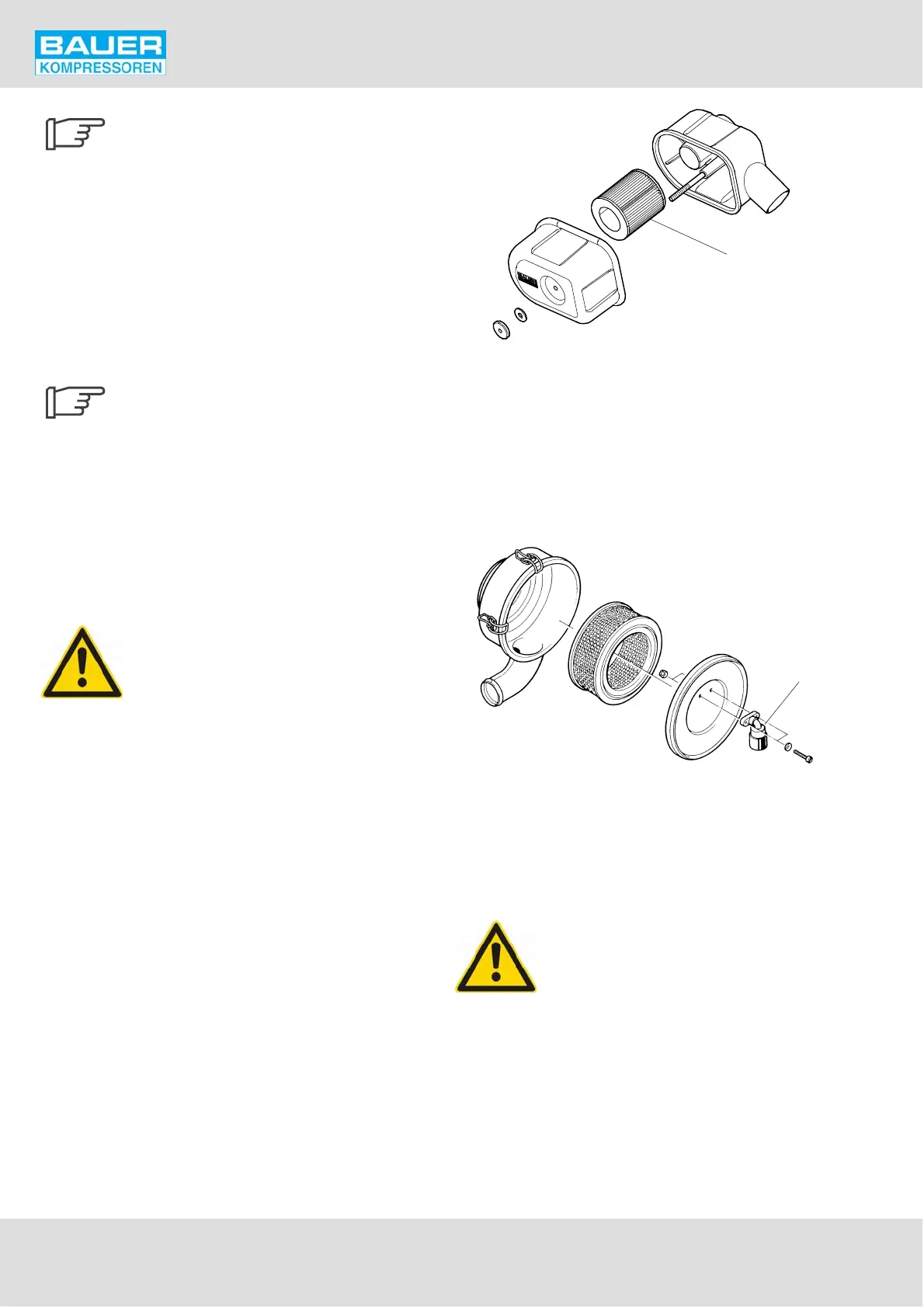

3.1.3. IK150, IK15.1, IK15.11, IK180, IK18.1

A dry micronic filter as shown in Fig. 15 is used to filter in

take air. It is fitted with a replaceable filter cartridge. The

service indicator changes colour from green to red when

the cartridge is clogged.

Fig. 15 Intake filter, IK150, IK180, IK18.1

1 Filter housing

2 Filter element

3 Cover

4 Service indicator

1

2

3

4

4. INTERMEDIATE SEPARATORS

The filter housing is subject to dynamic

load. It is designed for a certain number

of load cycles, which originate from an

abrupt pressure loss at condensate drain

(1 load cycle i.e. condensate drain = 1 de

pressurization, 1 pressurization). The

filter housing has to be inspected in

ternally by an expert after having reached

half of the determined number of load cy

cles. The inspections have to be arranged

by the operator.

The maximum permissible no. of load cycles is written in the

pressure vessel operating manual which is delivered with

each compressor unit.

Loading...

Loading...