V5−A/05/14

Instruction Manual w VERTICUS 5 Compressor Units

A-21

10. AUTOMATIC CONDENSATE DRAIN

10.1. COMPRESSOR BLOCKS IK12.14, IK150,

IK15.1, IK180

Description

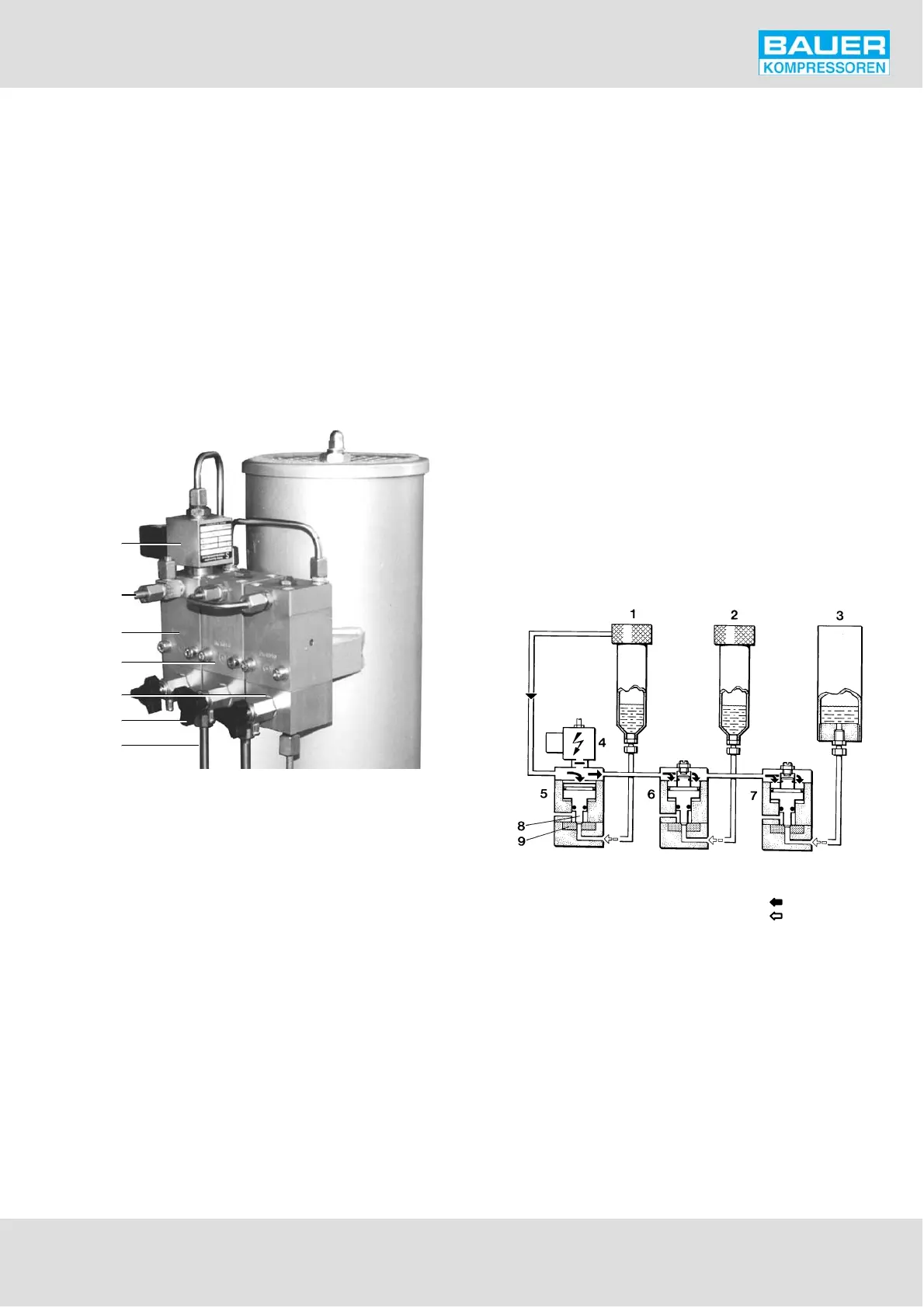

The automatic condensate drain unit (Fig. 22) drains the in

termediate separators after the 2nd and 3rd stage, and the

final separator after the 4th stage every 15 minutes during

operation.

In addition, the automatic condensate drain is designed to

drain these filters after shut-down of the compressor unit,

and to unload the compressor during the starting phase,

see paras. 10.4. and 10.5.

Fig. 22 Automatic condensate drain unit

1

2

3

4

5

7

6

1 3/2-way solenoid valve

2 Control medium connection

3 Condensate drain valve 2nd stage

4 Condensate drain valve 3rd stage

5 Condensate drain valve, 4th stage

6 Manual condensate drain tap

7 Condensate inlet connection (tube connector)

The automatic condensate drain system operates elec

tropneumatically and comprises the following main items:

Three pneumatically operated condensate drain valves,

one each for the intermediate separators after 2nd and

3rd stage and one for the oil and water separator after

the last stage. The condensate drain valves are of the

normally open type, i.e. they are closed by applying con

trol pressure.

A solenoid valve for control air, normally closed type,

mounted on top of the condensate drain valve for the

2nd stage.

A condensate manifold.

A condensate separator/silencer.

A condensate tank.

A bracket for mounting the drain unit on the com

pressor block or on the unit.

An electrical timer. The timer is mounted in the com

pressor control box on all units fitted with this optional

extra, or in a housing mounted on the unit or delivered

separately with bare compressor blocks.

Operation

The condensate drain valves are operated pneumatically

via a normally closed 3-way solenoid valve by an electrical

signal.

The required control air applied to the solenoid valve is

taken from the intermediate separator after the second

stage.

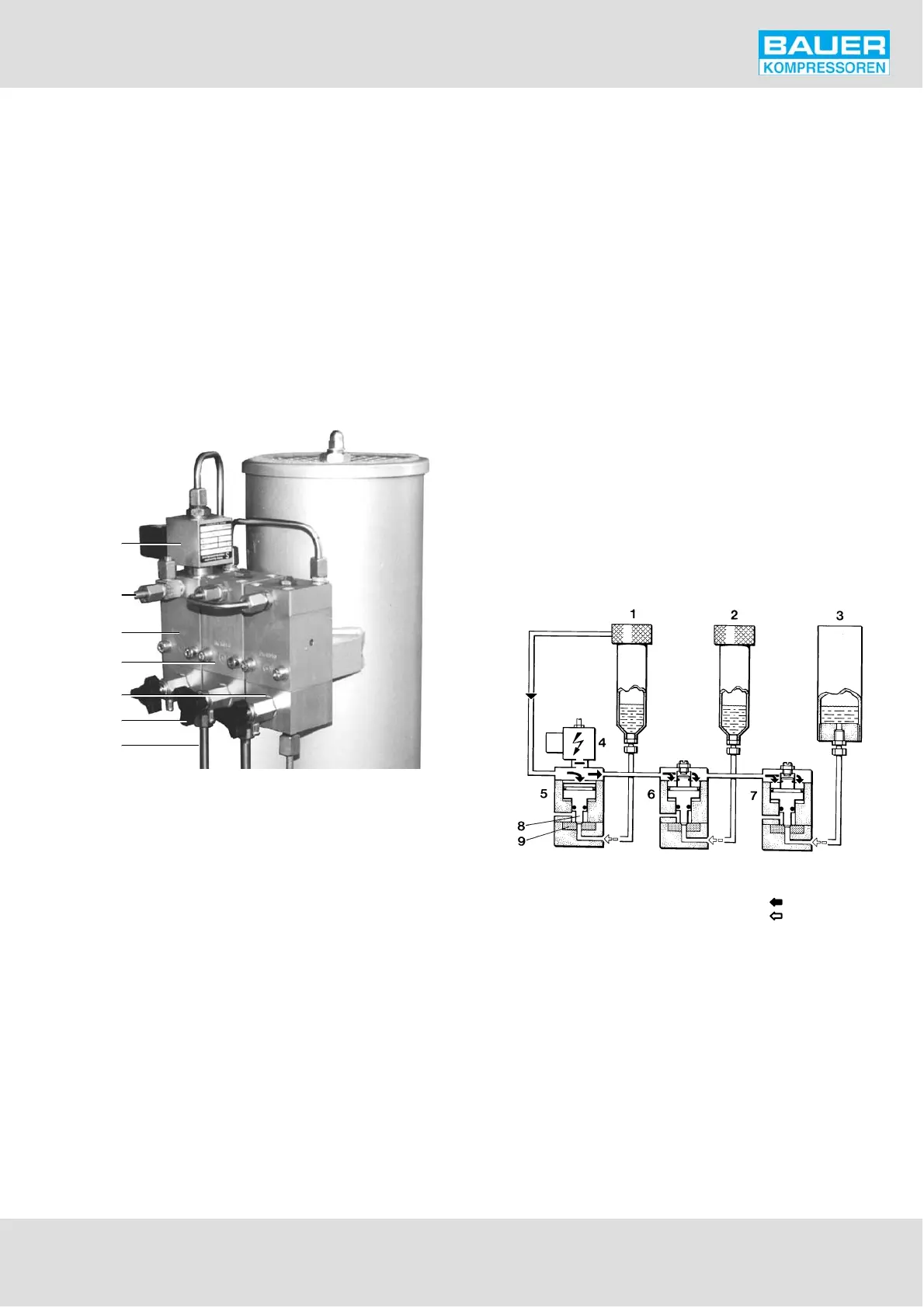

At compressor start, condensate drain valves (5), (6) and (7)

are open.

At start-up of the compressor, 3/2-way solenoid valve (4) is

energized and opens. Now control pressure is applied to

the condensate drain valves, (5), (6) and (7). The servo-pis

tons (8) are pressed onto valve seats (9) and the condensate

drain valves close.

The compressor delivers compressed medium to the con

nected systems.

Fig. 23 Normal operation

control pressure

condensate

1 Intermediate separator 2nd/3rd stage

2 Intermediate separator 3rd/4th stage

3 Oil and water separator after 4th stage

4 3/2-way solenoid valve

5 Condensate drain valve 2nd stage

6 Condensate drain valve 3rd stage

7 Condensate drain valve 4th stage

8 Servo piston

9 Valve seat

Condensate drain

Every 15 minutes, 3/2-way solenoid valve (4) is deenergized

for approx. 6 seconds by the timer and closes. The control

Loading...

Loading...