V5−A/05/14

Instruction Manual w VERTICUS 5 Compressor Units

A-18

cess by measuring the cartridge saturation within the filter

cartridge.

5.3. OIL AND WATER SEPARATOR

5.3.1. Description

The air leaving the final stage is cooled in the after-cooler

to approx.10 to 15 C (18-27 F) above ambient temperat

ure and then enters the oil and water separator. The oil and

water separator is part of the breathing air purification sys

tem. It separates reliably liquid oil and water particles from

the compressed air.

The oil and water separator is subject to

dynamic load. It is designed to withstand

a certain no. of load cycles. (1 load cycle

= 1 pressurization, 1 depressurization.)

at the specified pressure range. The oil

and water separator must be replaced when the max

imum permissible no. of load cycles has been reached.

Refer to the pressure vessel operating manual de

livered with the unit.

For the lay out of the complete system all components

(compressor, purification, storage cylinders, etc.) are to be

adjusted to each other the best possible way. The number

of starting cycles (4 per hour) must not be exceeded. Actual

running time per cycle should be min. 15 minutes in order

to reach an optimum between utilization ot the unit and

true life time.

The maximum recommended amount of four load cycles

per hour should not be exceeded. If it is possible to regulate

the operation of the unit to such a degree as to achieve four

load cycles per hour, in our opinion this would be an op

timum between usage and actual life.

5.3.2. Purifier

The filter housing consists of an anodized aluminium alloy

pipe with 100 mm external diameter. Both ends are

provided with fine threads on the inside.

The screw-in filter bottom contains inlet and outlet. For

connector threads see specifications, chapter 1.

The upper screw connection contains a pressure resistant

bushing for the electrical connections. The coaxial cable

which leads from the sensor to the control unit is connected

to the BNC connector located there.

5.3.3. Filter cartridges

The cartridge tube is made of aluminium. Cover and bottom

consist of pressure diecast aluminium. The cartridge cover

contains the sensor for the monitoring function and the clip

to facilitate changing of the cartridge.

Different cartridges are available depending on the re

quired air quality.

6. PRESSURE MAINTAINING / NON-

RETURN VALVE

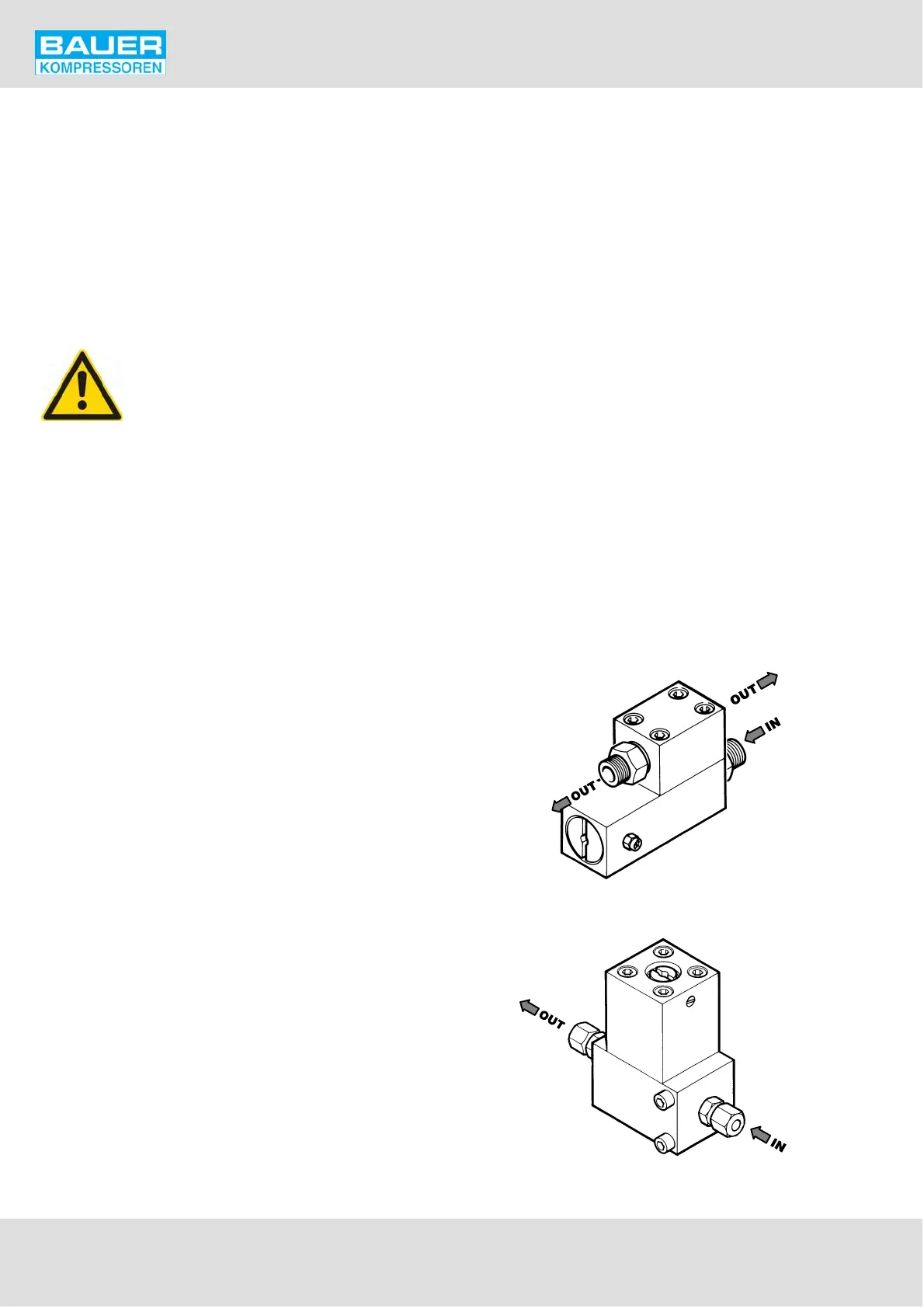

6.1. COMPRESSOR UNITS UP TO 350 BAR

A pressure maintaining and a non-return valve are provided

downstream of the filter system. Refer to flow diagram in

section F. Depending on the model, the combined pressure

maintaining/non-return valve is mounted on the frame of

the compressor unit, or on the outside of the housing. For

the compressor block it is delivered separately.

The pressure maintaining valve ensures that pressure is built

up in the filters even from the start of delivery, thus achiev

ing a constant, optimum filtration. It will also guarantee

proper working conditions for the final stage cylinder.

The pressure maintaining valve is adjusted to 150 10 bar

On units equipped with a filter system, an additional non-re

turn valve is mounted after the oil and water separator -

flanged directly to the filter head. It prevents already

filtered medium from flowing back from the downstream

filters when draining condensate from the oil and water

separator.

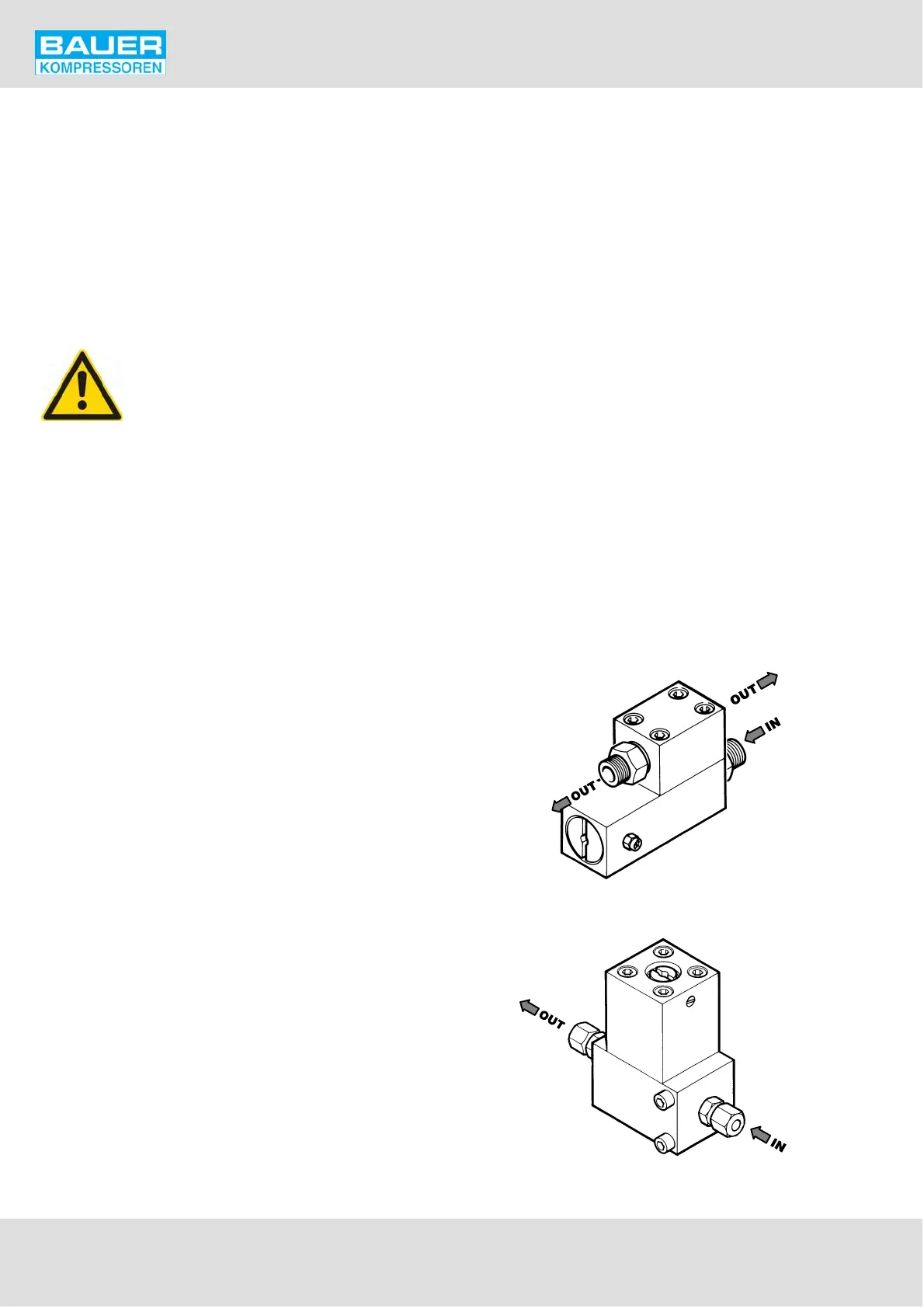

6.2. COMPRESSOR UNITS UP TO 420 BAR

On units with a maximum final pressure of up to 420 bar

(7,250 psi) the pressure maintaining/non-return valve KB

068275 (staninless steel) is mounted.

This pressure maintaining valve is adjusted to 280 10 bar

Fig. 17 Pressure maintaining/non-return valve, 350 bar

Fig. 18 Pressure maintaining/non-return valve, 420 bar

Loading...

Loading...