Instruction Manual w VERTICUS 5 Compressor Units

B-7

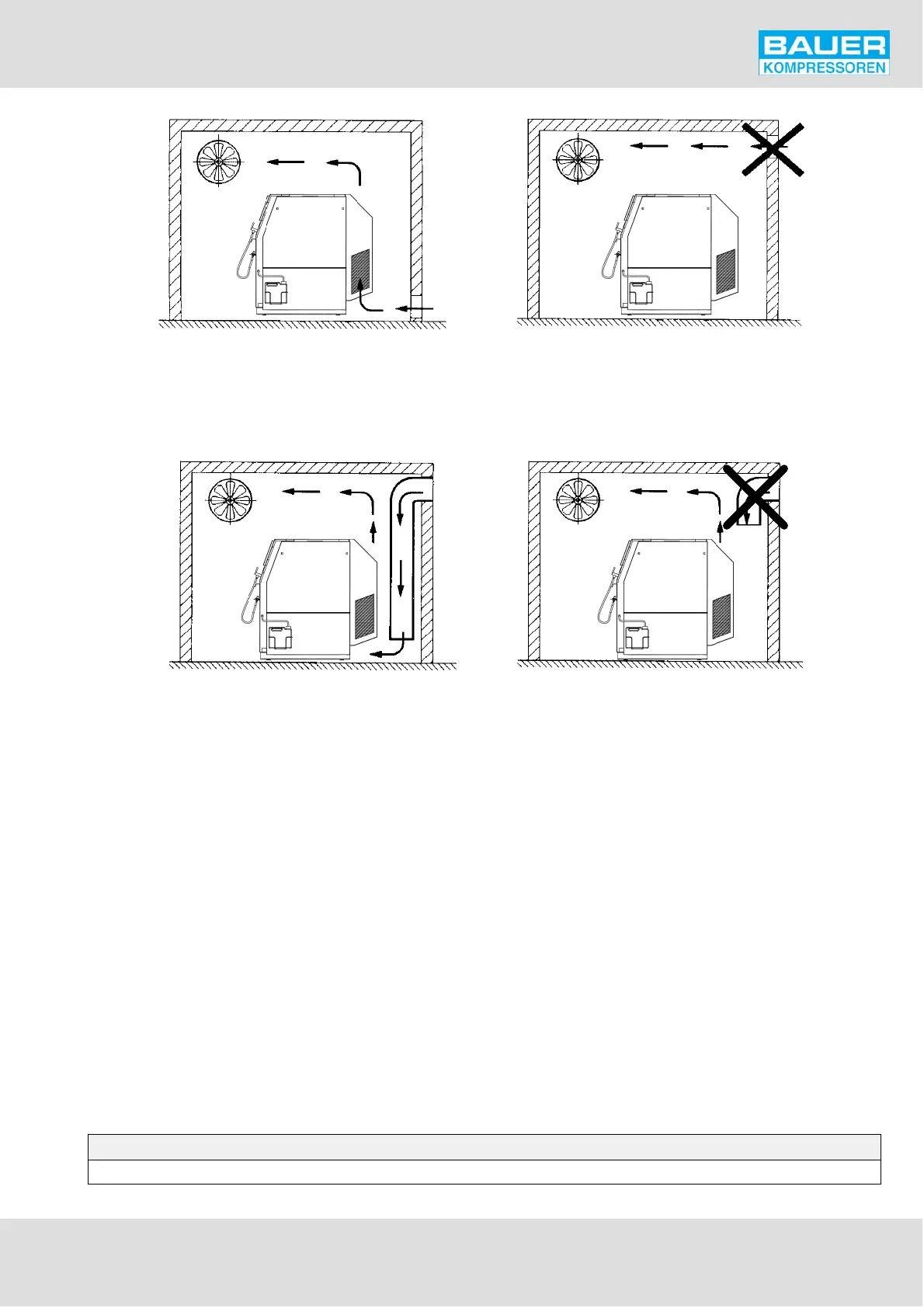

Correct: Air flows along an imaginary

streamline through the compressor

Incorrect: Cooling air does not re

ach unit

Fig. 92 Installation with artificial ventilation, example 1

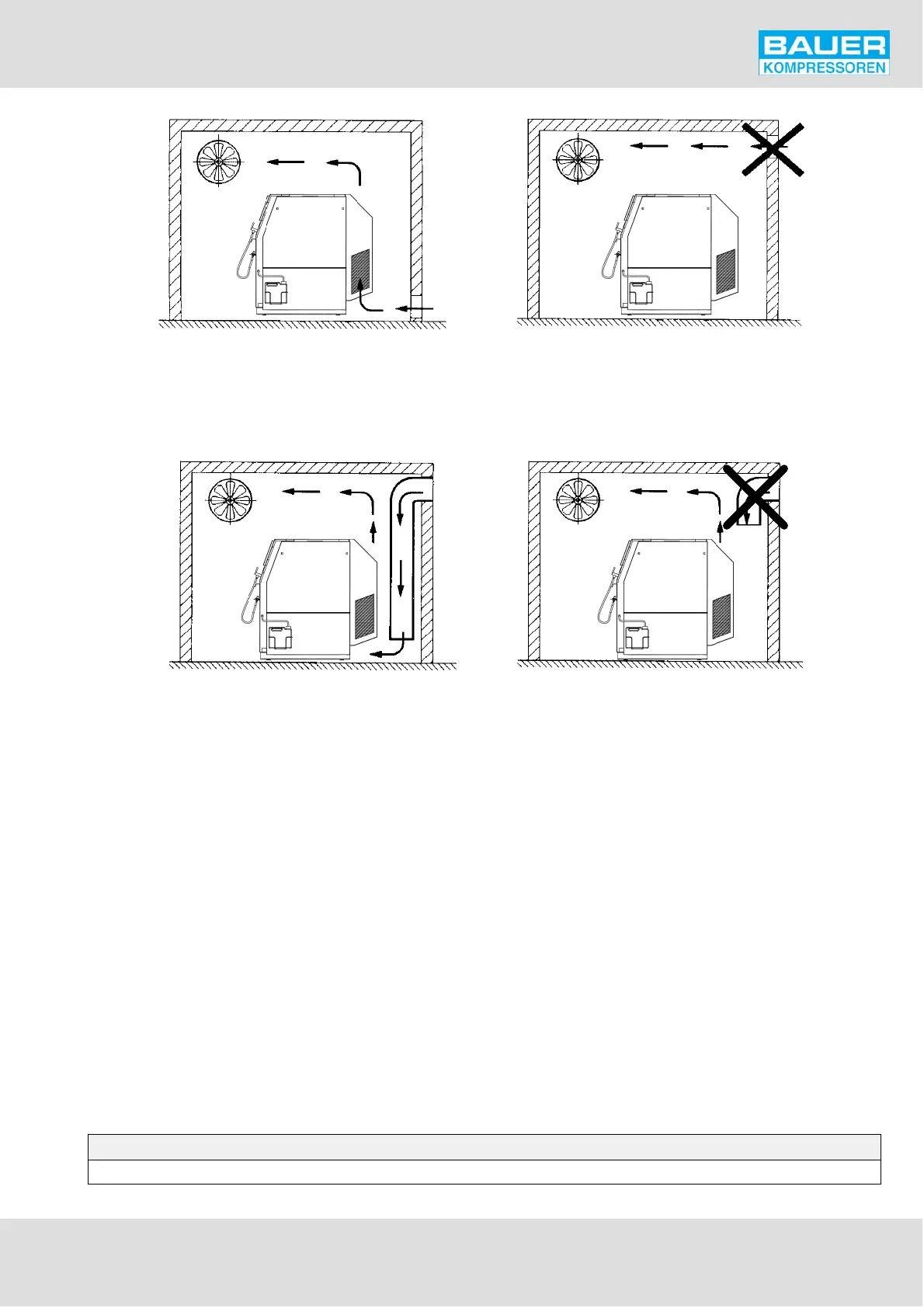

Correct: cooling air led directly to unit

Incorrect: cooling air duct does not reach

intake opening, intake duct too short

Fig. 93 Installation with artificial ventilation, example 2

2. ELECTRICAL INSTALLATION

For installation of electrical equipment observe the follow

ing:

- In section F. you will find the standard schematic dia

grams valid for the respective compressor unit. To con

nect the compressor control system, use only the dia

gram contained in the control box of the unit, because

any deviations from the standard diagrams according to

order are marked there.

- Observe regulations of local electricity supply company.

- Connection should be carried out by an expert only.

- Ensure correct installation of protective conductor.

- Check conformity of motor and control device tension

and frequency with those of electric network.

- The necessary cabling, main fuse and a main switch

(load-break switch) are to be provided by the customer.

Ensure that the main switch is for one unit only and is

clearly and immediately recognizable. Fusing must be

according to the electricity supply company's regula

tions. For units not connected through a plug, but per

manently installed, a main switch must be provided

which has a contact gap of 3 mm minimum on each

pole.

- Adjust motor protection, thermal overload relay. For

start over contactor adjust to motor amperage rating.

For start via star-delta contactor adjust to motor amper

age rating x 0.58.

For example: motor amperage rating = 10 Amp.:

Adjust relay to 10 x 0.58 = 5.8 Amp.

- Fuse motor correctly (see table below; use slow-blow

fuses, only).

FUSE TABLE

Motor type V 125 230 240 400 415 440 500 600 660

3-phase, 2,2 kW (star-delta starting) A 20 10 10 6 6 6 6 4 4

Loading...

Loading...