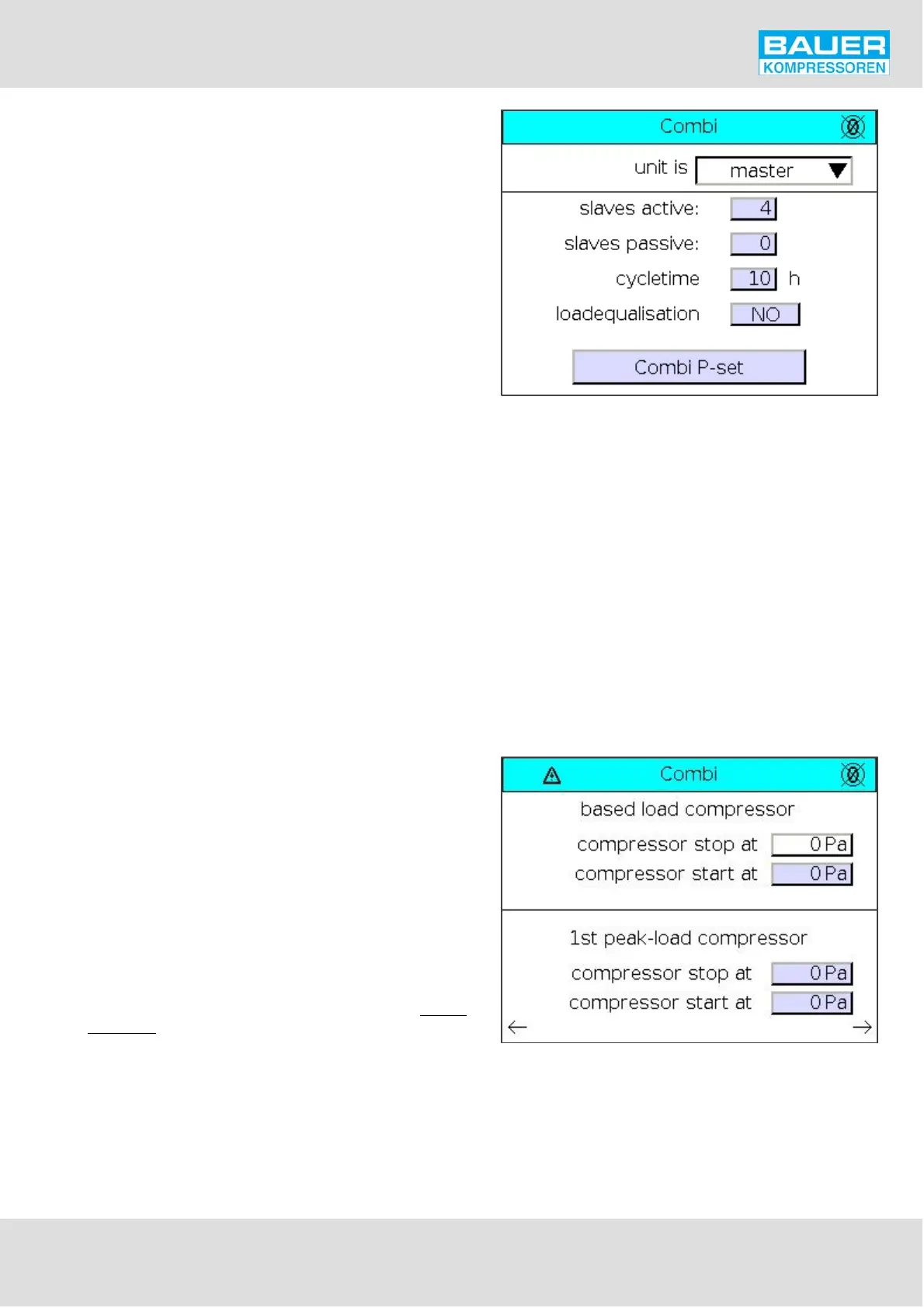

Fig. 59 Combined operation

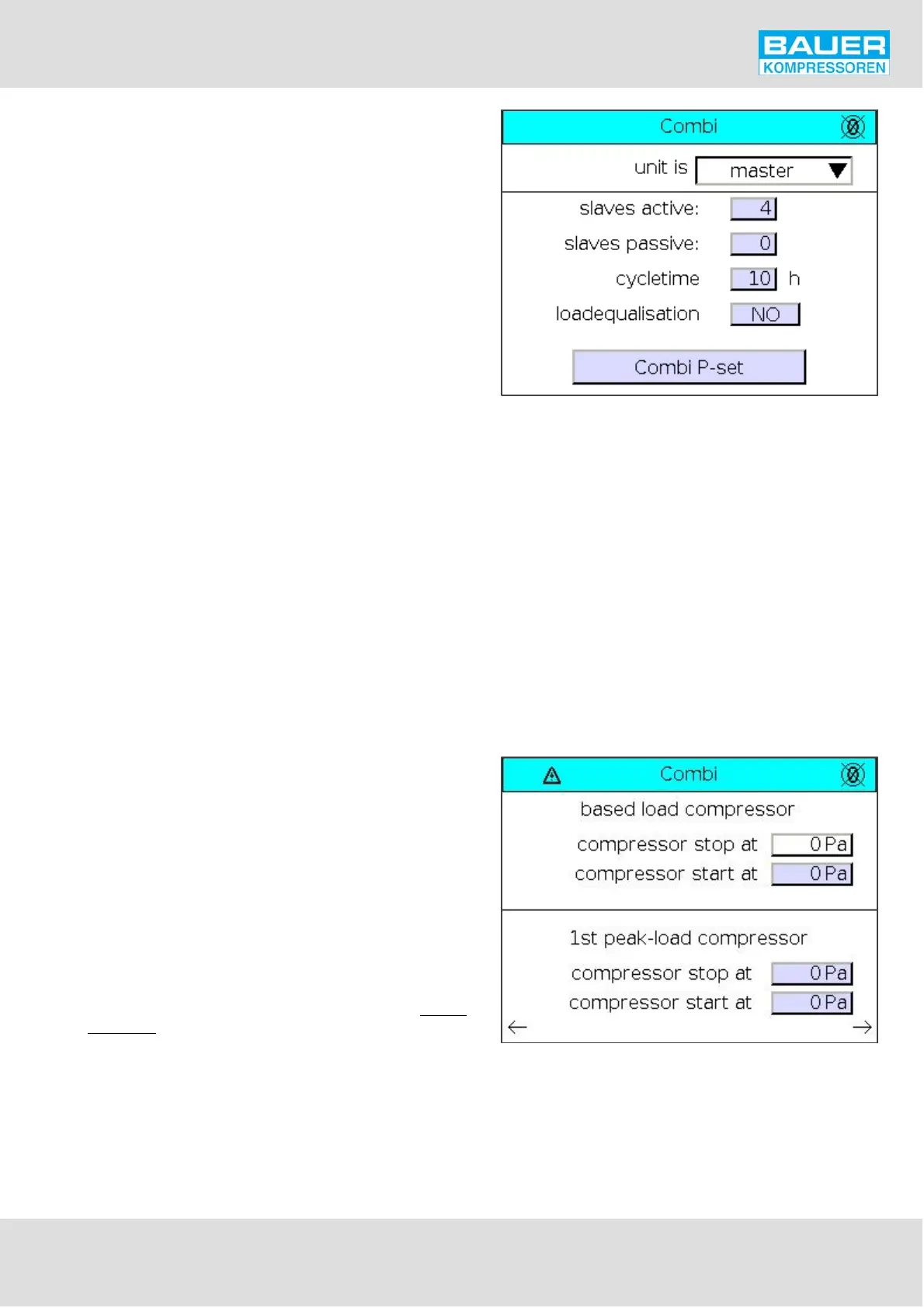

Fig. 60 Combination pressure

Instruction Manual w VERTICUS 5 Compressor Units

A-57

Combined operation

The combi page (Fig. 59) defines the status of the

compressor in a combined installation. The controller can

be declared as master or as slave. A master compressor

controls the whole combined installation; a slave

compressor is controlled by the master. No further settings

are necessary if the controller is set to „slave“. When

„master“ has been selected, the following parameters have

to be set:

Slaves active: number of compressors connected to the

master via a CAN-bus (only with appropriate control

system: B-Control II or B-Control extended). All active slave

compressors of the combination have to be set to Slave.

Refer to the instruction manual of the compressor.

Slaves passive: number of compressors controlled from

the master via switch-on and -off contacts.

Cycle time: defines the runtime (in hours) of the

compressors. Based load compressor and peak-load

compressors will be switched when the defined runtime is

over.

Loadequalisation: Select yes or no to enable or

respectively to deactivate the operating hours

loadequalisation. This effects that the compressor runtime

will be compared and a balanced working load will be

reached. The loadequalisation is automatically deactivated

as soon as the installation contains one or more passive

slaves.

Combi P-Set: Press the Combi P-Set button to open the

pressure settings page for the combined installation

(Fig. 60).

The Combi P-Set page enables to set start and stop

pressures for the based load compressor and the peak-load

compressors. Once the cycle time is over, the operating

hours of all compressors are compared and the compressor

with the lowest number of operating hours is declared as

based load compressor, the compressor with the highest

number of operating hours as last peak-load compressor.

In order to ensure a balanced load of all compressors, the

combined pressure must be set so that the resulting running

time for the based load compressor is higher than the

running time of the 1st. peak load compressor. This in turn

must be higher than the running time of the 2nd. peak load

compressor, and so on. Consequently under normal

conditions the start pressure of the based load compressor

("Compressor start at ...“) must be higher than the start

pressure of the 1st. peak load compressor. In the same way,

the start pressure of the 1st. peak load compressor must be

higher than the start pressure of the 2nd. peak load

compressor, and so on.

With correct configuration, the operating hours of all

compressors (see Chap. 11.4.6.) will increase equally.

Loading...

Loading...