V5−A/05/14

Instruction Manual w VERTICUS 5 Compressor Units

A-17

4.1. FUNCTIONAL DESCRIPTION

Intermediate separators are mounted after 2nd and 3rd

stage and at five stage compressor IK18.1 also after the 4th

stage. The separators are designed to remove water and oil

accumulating due to cooling the air down after the com

pression process.

Separation is achieved by means of the centrifugal action

provided by a vortex plate.

4.2. 1ST STAGE SEPARATOR (OPTION)

For severe environmental conditions, especially high tem

peratures and humidity, an additional separator after the

1st stage can be provided. Refer to flow diagram in chapter

F. This separator is similar to the separators as described

above.

5. FINAL SEPARATOR / FILTER SYSTEM

5.1. GENERAL

Breathing air compressor units are fitted as standard with

an air purification system: filter system P61. As an option,

filter system P81 for increased filter cartridge lifetime is

available.

Unlike other filter systems the SECURUS filter system en

sures continuous monitoring of the breathing air purifica

tion parameters while the air is still in the regeneration pro

cess. The influences of

ambient temperature

ambient humidity

temperatures of the compressor and regeneration sys

tem are taken into consideration.

The exchangeable SECURUS cartridges are designed for

drying of air

adsorption of aromatic components (aerosols)

partial conversion of CO into CO

2

partial adsorption of CO

2

The quality of the breathing air produced conforms to the

national and international

DIN EN 12021

STANAG 1079 MW

British Standard 4001

US CGA Spec. G.7.1

Canada CSA Standard Z 180.1

Australian Army Standard 5017

It is impossible to exceed the cartridge utilization time since

a preliminary warning message indicates the approaching

saturation of the cartridge. Depending on the size of com

pressor used, the prewarning message will appear between

1 and 7 hours prior to cartridge saturation. If the cartridge

is not replaced after indication of the preliminary warning

message, the B-CONTROL compressor control will auto

matically shut down the compressor as soon as the cart

ridge has been exhausted. The compressor cannot be

turned on as long as no cartridge has been inserted.

The SECURUS filter system operates in the FAIL-SAFE

mode: the compressor will be shut down if the circuit

between the control unit and the sensor is interrupted.

As soon as the preliminary warning

message appears or, at the latest, after

the B-CONTROL unit has shut down the

system, the cartridges of all filters within

the systems must be changed according

to D-5.2.2. For description and operation of the B-

CONTROL system see chapter A-11.

5.2. APPLICATION AND SUMMARY DESCRIP

TION

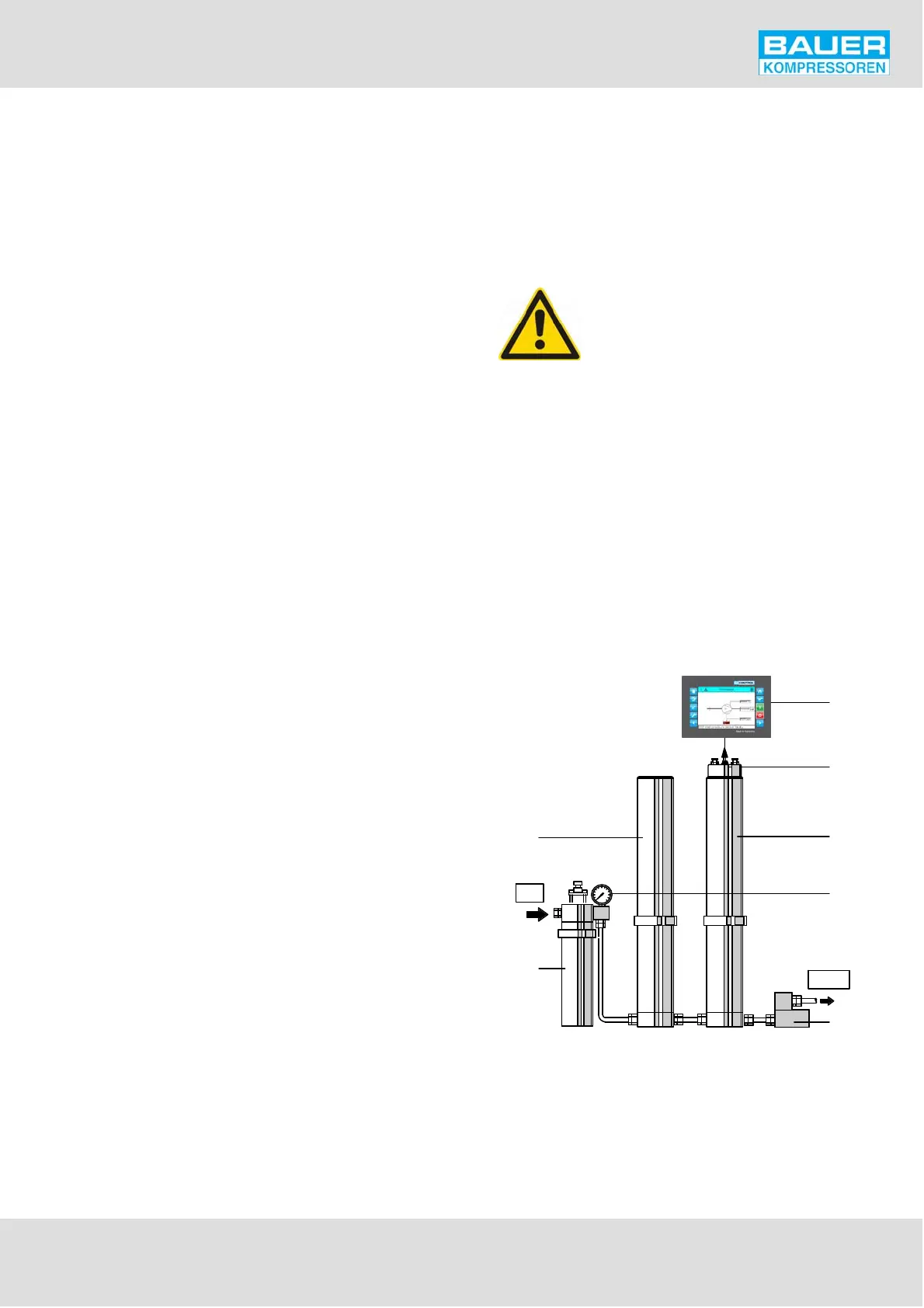

The filter system (Fig. 16) consists of:

Oil and water separator

Non-return valve between separator and purifier

Drying filter (filter system P81 only)

High pressure purifier

SECURUS sensor head

a)

Venting valve with pressure gauge

Pressure maintaining/non-return valve

Fig. 16 Filter system with SECURUS monitoring

5

2

3

4

OUT

6

IN

7

1

The system is integrated into the compressor unit, i.e. the

filters and other components are mounted on the frame,

the pressure gauges are situated at the filling panel. If the

SECURUS monitoring system is provided, the breathing air

regeneration process and the degree of dryness of the air

are continuously monitored during the regeneration pro

a) Optional extra

Loading...

Loading...