V5−A/05/14

Instruction Manual w VERTICUS 5 Compressor Units

A-28

11. ELECTRICAL SYSTEM

11.1. GENERAL

This section describes the standard electric control and

electronic monitoring system of the compressor unit. The

electric control unit is an optional extra for all compressor

units, i.e. the amount of built-in components varies depend

ing on order.

For schematic diagrams, see section F.

The electrical equipment of the compressor unit consists of:

drive motor M1

electric control system

To start the electric motor and enable the functioning of the

controls as well as the monitors, the following components

are essential:

main switch Q1 and

main fuse, both to be installed by the customer.

11.2. EMERGENCY SHUTDOWN

Every unit has an “Emergency Shutdown” push button.

Pressing this push button interrupts the control voltage and

the unit shuts down.

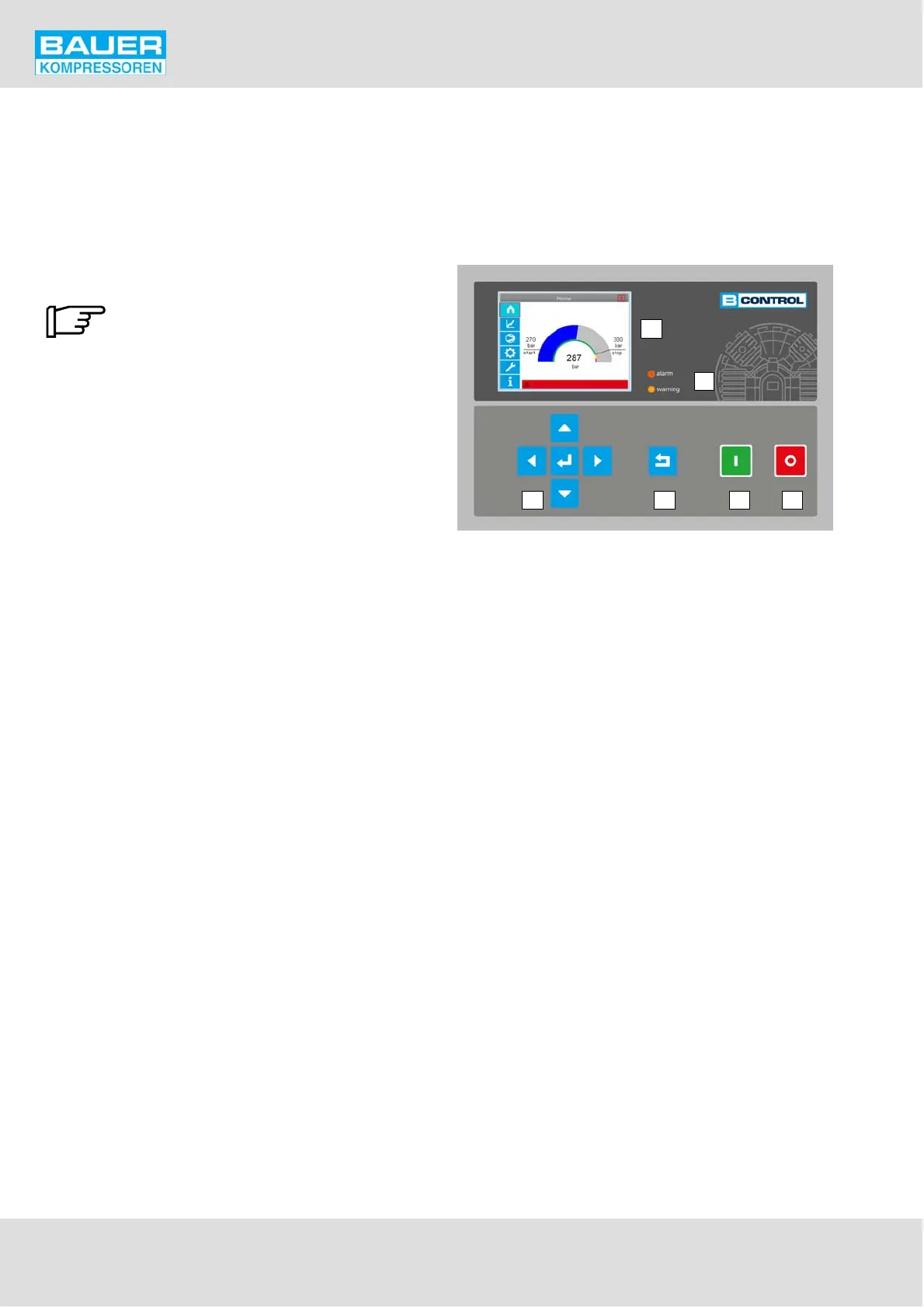

11.3. B-CONTROL MICRO (standard for all

Verticus 5 compressor units)

11.3.1. General

The BAUER B-Control Micro is a freely-programmable

electronic compressor control system. Communication

with the operator is via a colour display and various

different cursor buttons. The compressor control system is

specially programmed for BAUER compressors.

The compressor control system facilitates, among other

things, the display and monitoring of all operationally

relevant parameters, the determination and monitoring of

the maintenance intervals and the recording of all

messages. In addition, the compressor control system

offers three freely-configurable operating modes to be

chosen:

Semi-automatic: the compressor switches off after

manual starting of the compressor when the final

pressure is reached (one pressure value or both pressure

values, depending on the configuration). Automatic

switching on again after the pressure falls below the

switch-on pressure does not take place in this operating

mode.

Fully automatic: after the compressor is started

manually using the ON button, the control system

operates depending on the pressure. If the final pressure

or compressor stop value is exceeded (one pressure or

both pressure values, depending on the configuration)

the compressor switches off. If the pressure falls below

the switch-on pressure or the compressor start value

(interlinked two switch-on values depending on the

configuration), automatic incorporation of the

compressor takes place. This repeats until the

compressor is switched off manually.

Fig. 35 B-Control Micro

1 2

3

4

56

1 Compressor ON

2 Compressor OFF

3 Filter display

4 Colour display

5 Back button

6 Navigation buttons

Combined operation: the B-Control Micro allows up to

4 compressors to be controlled as slaves in a so-called

combined operation (networked operation). The

master installation requires a B-Control II control

system. A combined operation compressor installation

generally serves to provide increased air demand with

reliability and, to this end, to switch the compressors

OFF and ON, so that the pressure in the target vessel, or

the level in the source (glassblowing) is kept as constant

as possible and to balance the running times of the

compressor as far as possible. The running of

compressors in a combined operation provides

redundancy which ensures compressed air supply in the

event of a fault or when maintenance is being carried

out. The programmed basic/peak load operation makes

sure that the required volume is always provided,

independent of the pressure drop, and that the basic

load is transferred on a time basis from compressor to

compressor. The compressors can either be called up

actively, i.e. via a bus system with appropriately

equipped control system (B-Control Micro or B-Control

extended), or passively by remote on/off contacts. The

control via simple switching contacts also allows the

connection of older compressor installations with

Comp-Tronik control. In order to ensure optimum

function of the combined unit it is necessary to adapt

the operating parameters according to the application

concerned. That is the task of an experienced plant

Loading...

Loading...