Instruction Manual w VERTICUS 5 Compressor Units

A-25

pressure build-up of the compressor. The compressor deliv

ers compressed medium to the connected systems.

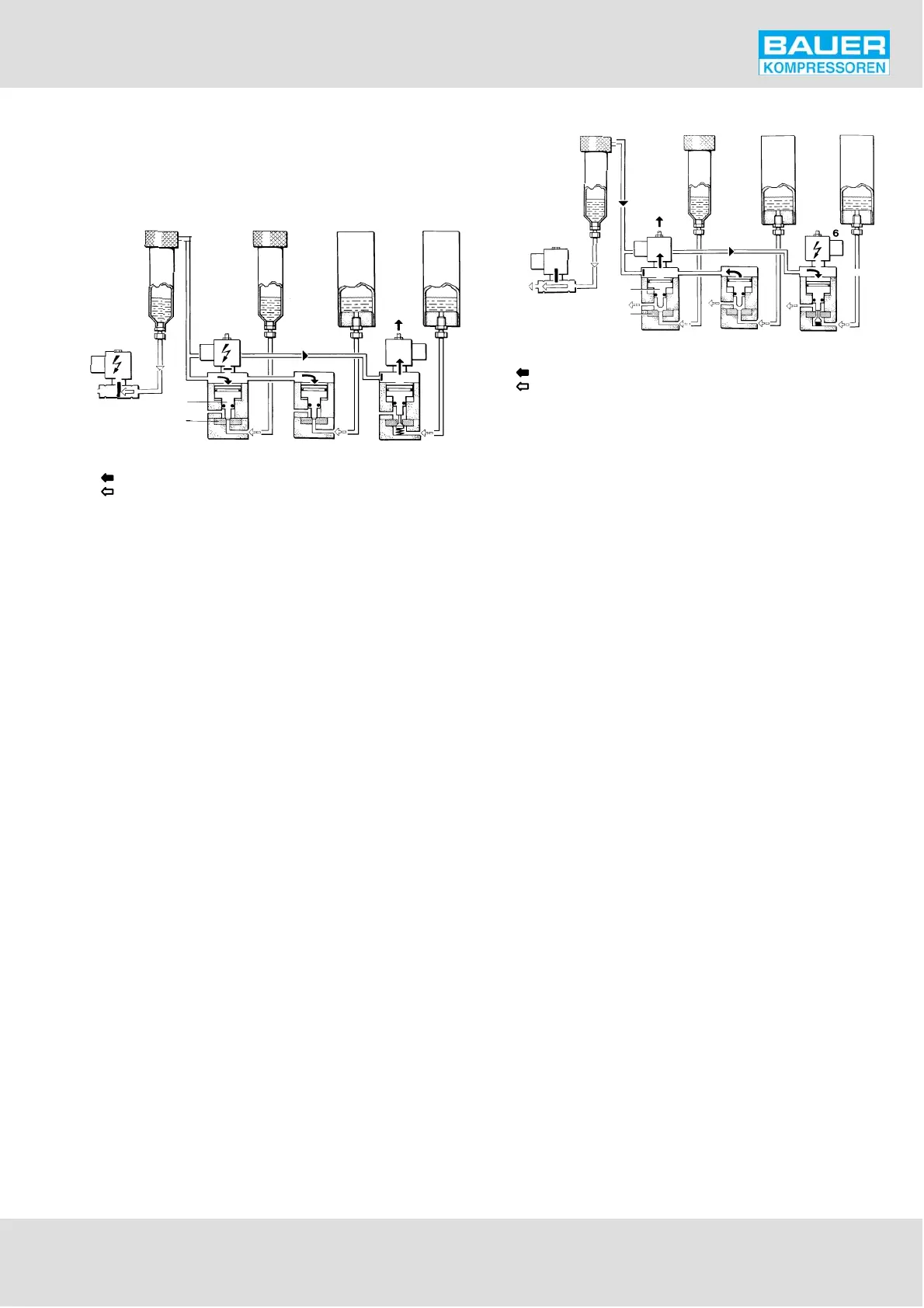

Fig. 30 Normal operation

control pressure

condensate

1

234

56

7

8

1 Condensate drain valve 2nd stage

2 Condensate drain valve 3rd stage

3 Condensate drain valve 4th stage

4 Condensate drain valve 5th stage

5 3/2-way solenoid valve 3rd/4th

stage

6 3/2-way solenoid valve 5th stage

7 Servo piston

8 Valve seat

Condensate drain

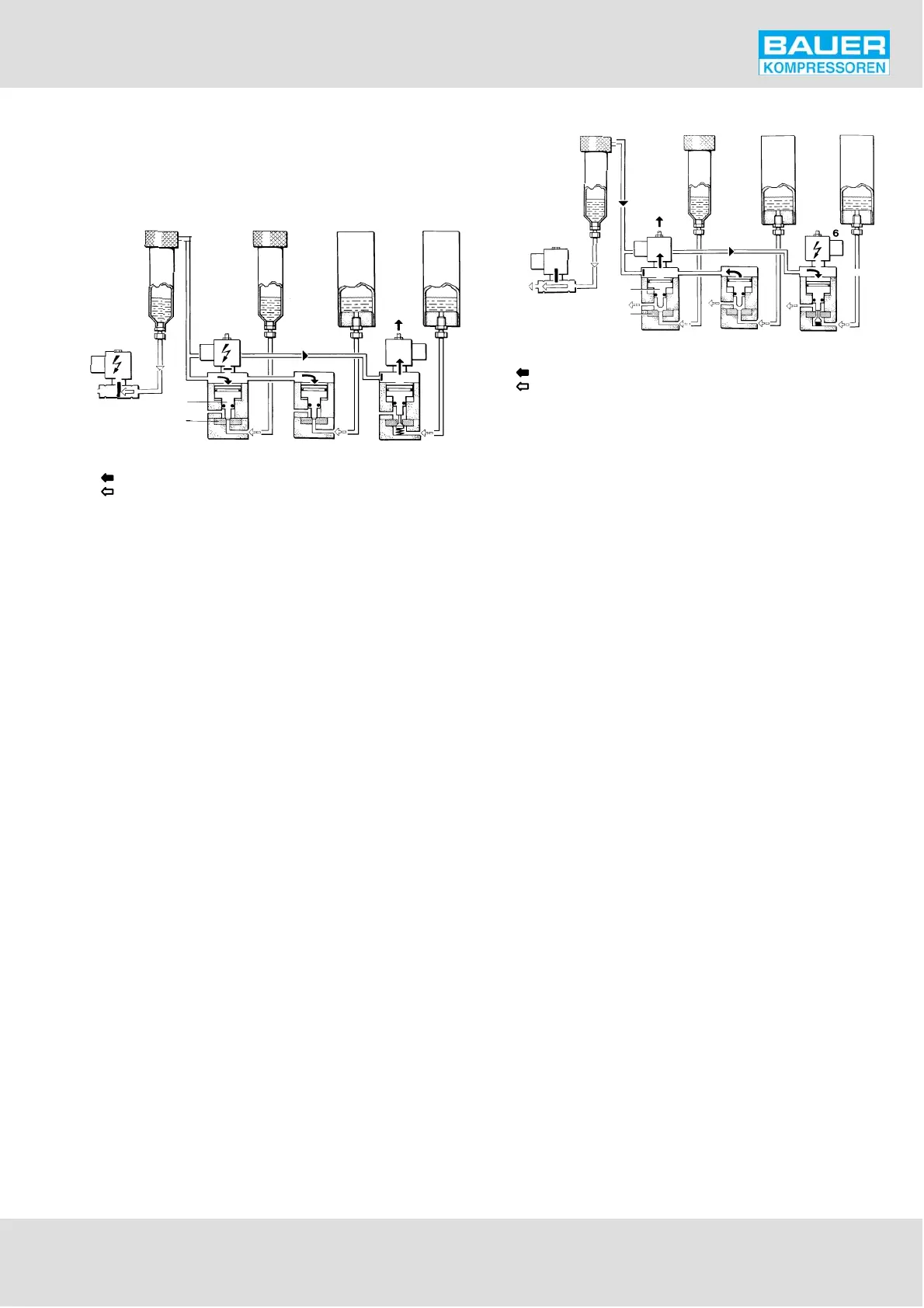

Every 15 minutes, 2-way solenoid valve (1) and 3/2-way

solenoid valve (5) are deenergized for approx. 6 seconds by

the timer and close. The control pressure is relieved from

the servo-pistons (7) of the condensate drain valves (2) and

(3) and the pistons are raised from the valve seats (8) by the

2nd stage pressure. The condensate from the intermediate

separators after 2nd, 3rd and 4th stage is drained. After 6

seconds, the solenoid valves are de-energized, and the sys

tem returns to normal operation.

Also every 15 minutes, but independently from solenoid

valves (1) and (5), 3/2-way solenoid valve (6) is energized for

approx. 3 seconds by the timer and opens. The control pres

sure pushes down the servo-pistons of the condensate

drain valve (4), the piston is raised from the valve seat (8)

and the condensate from the oil and water separator after

last stage is drained. After 3 seconds, the solenoid valve (6)

closes again and shuts off the control medium path from

the 2nd stage separator and the valve closes due to spring

pressure. Pressure is built-up from the compressor.

Fig. 31 Condensate drain

control pressure

condensate

1

234

56

7

8

1 Condensate drain valve 2nd stage

2 Condensate drain valve 3rd stage

3 Condensate drain valve 4th stage

4 Condensate drain valve 5th stage

5 3/2-way solenoid valve 3rd/4th

stage

6 3/2-way solenoid valve 5th stage

7 Servo piston

8 Valve seat

10.4. START UNLOADING

The unloading during the starting phase of the compressor

is effected due to the lack of control air/gas immediately

after switching on the unit. After the compressor has at

tained nominal speed, control air/gas flows to the condens

ate drain valves which close and the compressor starts de

livering to the consuming device.

10.5. STANDSTILL DRAINAGE

At compressor shut-down, solenoid valves are deenergized

and open.

The servo pistons are raised by the residual pressure within

the separators. The valves open, and the separators are

drained at standstill of the compressor unit.

10.6. CONDENSATE COLLECTOR 10 ltrs.

BAUER Verticus 5 units are equipped as standard with a 10

liter condensate collector which can be mounted at the

front or the left side as required.

10.7. CONDENSATE COLLECTOR 40 ltrs.

(OPTIONAL)

Optionally, BAUER Verticus 5 units can be fitted with a 40

liter condensate collecting system (Fig. 32). It serves as a

central collector of the accumulated condensate and separ

ates the condensate from the air.

The condensate collecting tank is equipped with a mechan

ical level indicator for optical pre-warning for exchange

when due. In addition, the compressor can be automatic

Loading...

Loading...