3

1

2

Instruction Manual w VERTICUS 5 Compressor Units

B-9

4. CONNECTING STORAGE BOTTLES

(OPTIONAL)

Compressor units with factory installed storage bottle(s) on

a common base frame (see drawing 073314 or 073791, re

spectively in section F.). The pressure outlet of the com

pressor unit is already routed to the storage bottle. The cus

tomer's pressure system will then be connected directly to

the storage bottle.

The pressure connection is situated on the upper bottle

connector at the T connector suitable to connect tubes with

an outer diameter of 10 mm. A detachable adaptor 4 8/10

mm enables connection of either 4 8mm as well as 4 10 mm

tubes. The adaptor is standard delivery scope.

Note that the upper tube connectors are sealed for trans

portation with plugs to protect the storage bottles from hu

midity and soil. Remove the plugs to connect the pressure

line system to either connector.

The storage bottles are fitted with a condensate drain valve

mounted at the lower console.

Do not connect the lower bottle connec

tion (condensate drain outlet) to the pres

sure line system! This connector is not

suitable for high pressure and severe

damage or injuries may occur if connec

ted to the high pressure system.

5. TAKING INTO OPERATION

5.1. PREPARATION FOR OPERATION

All compressor units are tested prior to

delivery to the customer, so after correct

installation of the unit there should be no

problem putting it into operation, ob

serving the following points:

- Prior to first operation read Instruction Manual care

fully. Make sure that all persons handling the com

pressor and the filling station are familiar with the func

tion of all controls and monitors. Observe the WARN

INGs in chapter C-1.1.

- Depending on the model range, some compressor units

are delivered without oil in the crankcase. In this case,

the first filling quantity is delivered separately in the con

signment. Prior to first operation fill with oil according

to chapter D-2. After taking unit into operation after a

standstill period of 2 years or more change compressor

oil. When using a mineral oil change oil after one year.

- Prior to each operation check the oil level according to

chapter D-2 and determine whether maintenance is ne

cessary in accordance with chapter D-1.

- Prior to first operation or operation subsequent to

maintenance or repairwork, turn the compressor manu

ally using the flywheel to ensure that all parts are turning

free. Check that all fastening bolts and threaded pipes

are secure and sealed, if necessary tighten them to the

correct torque value.

- Immediately after switching on the system for the first

time check the direction of rotation of the motor for

compliance with the arrow on the unit. If motor turns in

the wrong direction, the phases are not connected

properly. Shut down unit immediately and interchange

two of the three phase leads in the switch box. Never

change leads at the motor terminal board.

The oil pump will operate in the correct

sense of rotation, only. Otherwise, no oil

pressure will be built up resulting in dam

age of the compressor block.

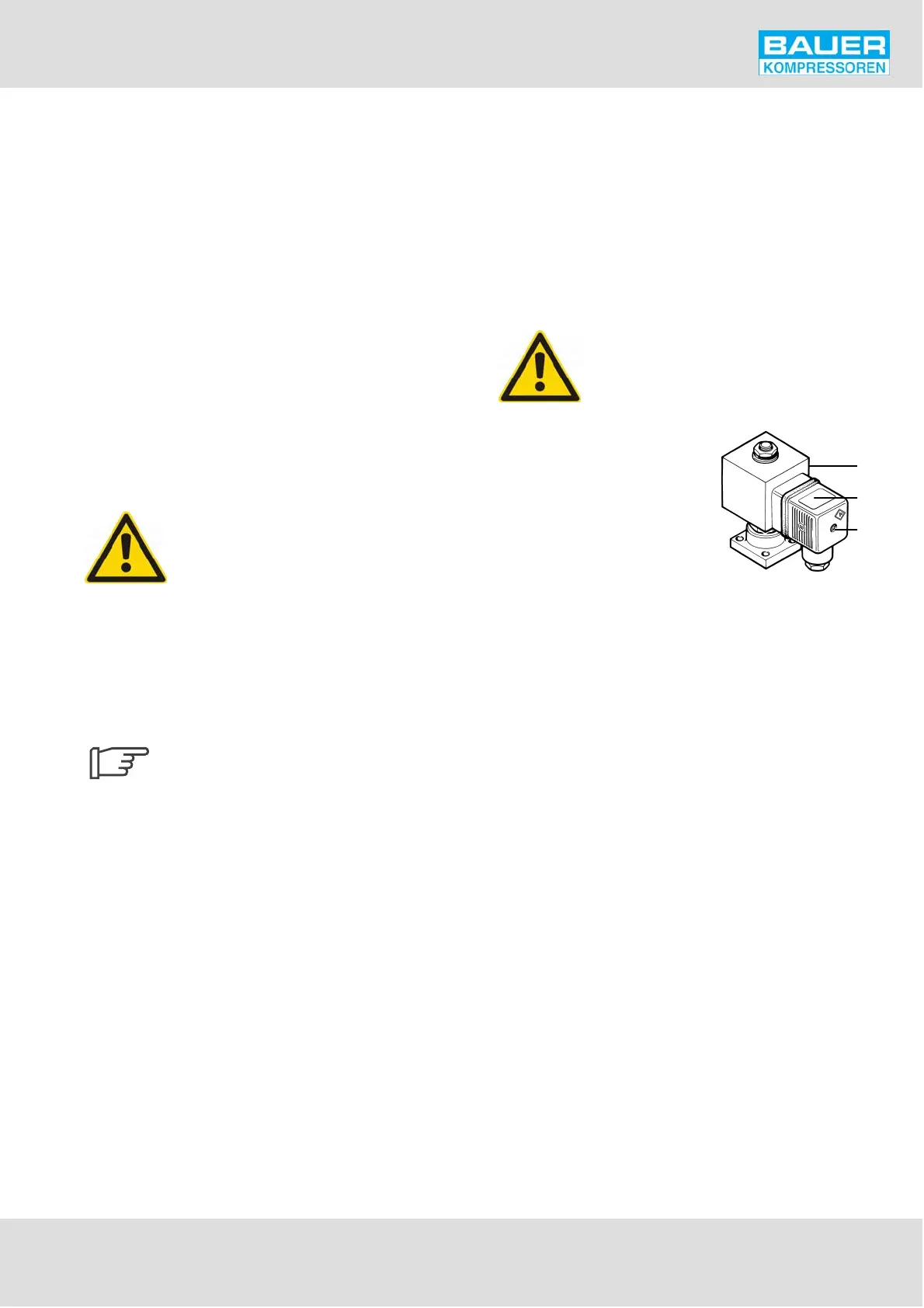

- Prior to first operation or op

eration subsequent to repair

work operate unit for at least

10 minutes with open con

densate valves (pressureless)

to ensure proper lubrication

of all parts before pressure is

built up. To keep drain valves

open, loosen screw (3) on coil

(1) and pull plug (2) from

solenoid valve.

- Open the outlet valve, this must be open during opera

tion. Close only for servicing the compressor to avoid

gas escaping from connected receivers.

- Every time the unit is started up check all systems for

proper operation. If any malfunction is observed stop

unit immediately and find the cause of the fault or call

the service department.

Loading...

Loading...