Introduction to the diagnostic system

Multi axis servo system - AX800012

Version: 1.1

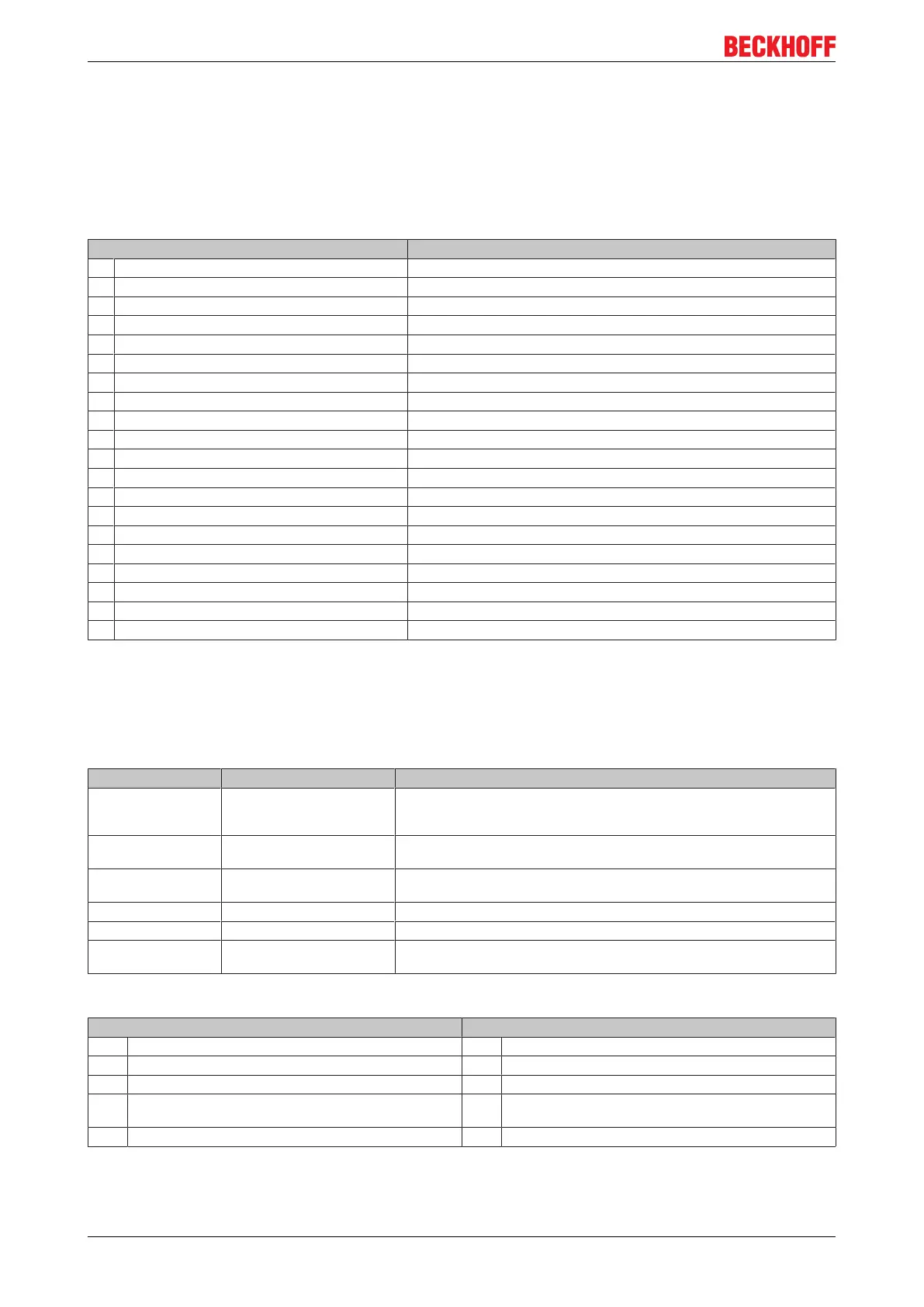

Diagnostic type

Each diagnostic message is assigned to a diagnosis type that contains the type group of the diagnostic

object. In total, there are 20 different diagnosis type groups (see table).

The diagnosis type groups 0 to 16 differ from the rest because the error counters are read directly via the

associated CoE object. The CoE object is called 0x2C1E:x (DeviceMain error counter) and, analogous to the

diagnosis type groups, has 17 sub-objects. Each of these sub-objects has the same name as the assigned

diagnosis type group.

Diagnosis type group Description

0 Motor overload shut down Motor overloaded

1 Motor overtemperature shut down Motor temperature exceeded

2 Drive overtemperature shut down Axis module temperature exceeded

3 Control voltage error Error in the 24V power supply

4 Feedback error Error in the feedback system

5 Commutation error Commutation error

6 Overcurrent error Overcurrent error in the motor phases

7 Overvoltage error Overvoltage in DC link

8 Undervoltage error Undervoltage in DC link

9 Power supply phase error Phase error in the supply module

10 Communication error Communication error

11 TorqueOff with emergency brake Torque-free axis with emergency braking

12 Motor connection error Motor connection error

13 Safety STO error Axis enabled and STO active

14 Overspeed error Speed exceeded

15 Motor Brake connection error Motor brake connection error

16 DC link connection overcurrent error Overcurrent error in the DC link

17 Warning A warning has no effect on the AX8000.

18 Information Information has no effect on the AX8000.

19 Information without history entry Information has no effect on the AX8000.

Reaction

The AX8000 can react in different ways to a diagnostic message. See also "AX8000 Diagnostic Messages".

In total there are seven different types of reaction, sorted hierarchically.

Since not all types of reaction are implemented, the next executable type of reaction is executed in the case

of an inexecutable reaction. The lowest type of reaction in this hierarchy is "torque-free".

Execution hierarchy Type of reaction Description

1 NC control The reaction of the AX8000 is controlled by the NC. The reaction time in which

the AX8000 takes control can be parameterized (see "AX8000 Diagnostic Mes-

sages")

2 "Closed loop" ramp The axis is brought to a standstill in a controlled manner. The ramp is parame-

terizable.

3 "Open loop" ramp The axis is brought to a standstill in a controlled manner. The ramp is parame-

terizable.

4 Emergency brake The motor is ramped down.

5 Torque-free The AX8000 switches the axis torque-free.

- No Reaction No reaction takes place; the AX8000 remains in the normal operating condi-

tion.

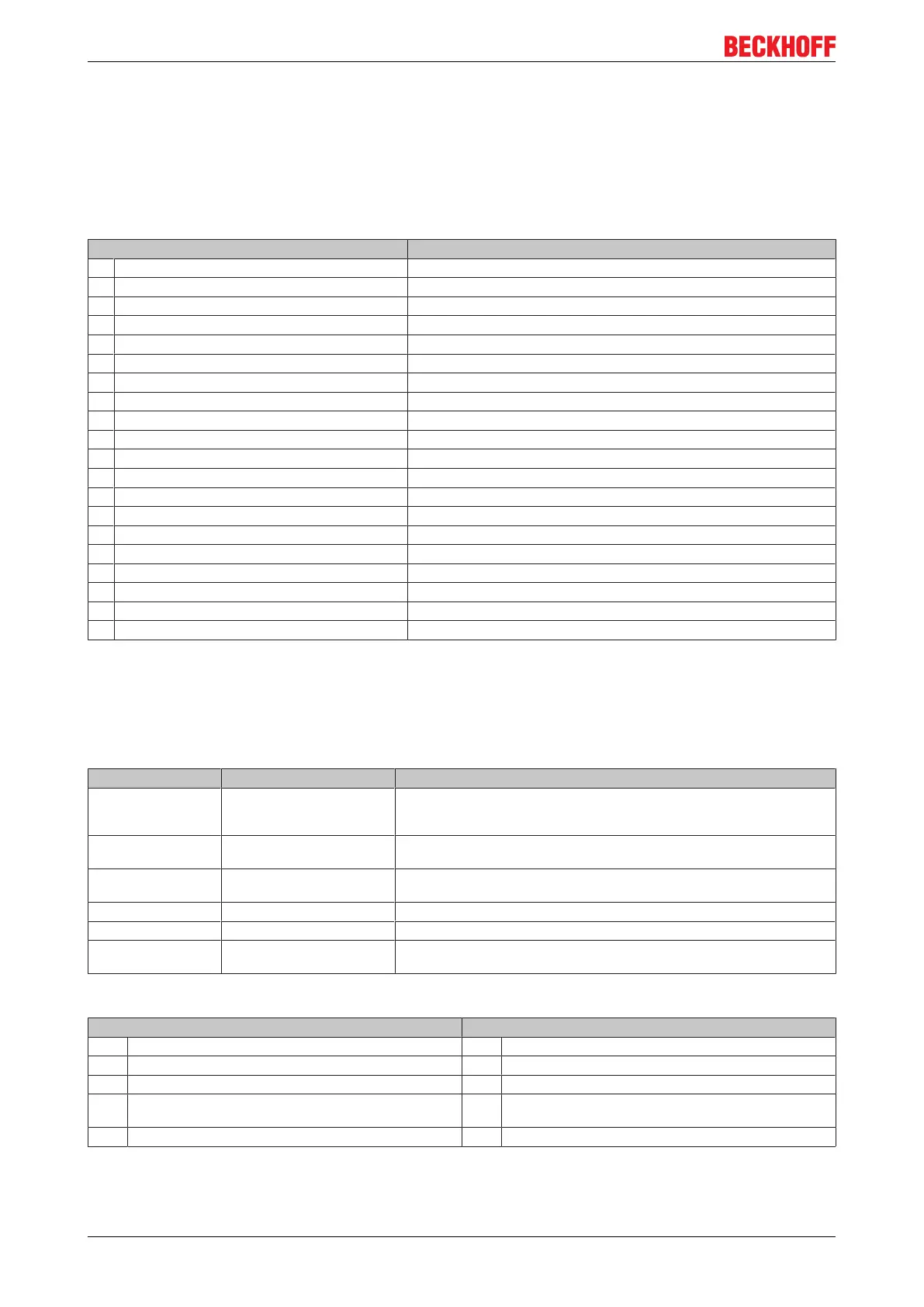

Examples of the hierarchical reaction execution

Expected reaction according to diagnostic Reaction performed by AX8000

1 NC control 2 "Closed loop" ramp

2 "Closed loop" ramp 2 "Closed loop" ramp

3 "Open loop" ramp 5 Torque-free

4 Emergency braking 4 or 5 For asynchronous motors this is followed by DC braking, for

synchronous motors torque-free

5 Torque-free 5 Torque-free

Loading...

Loading...