85

the luminosity of the photometric system. The lamp must be changed with the analyzer in sleeping mode. If

the analyzer is on standby mode, the program shuts it down automatically. The lamp must never be touched

with ngers. Once the new lamp has been installed and the covers of the optic and rotor put back, access the

change lamp utility and press the Test button. The program starts up the analyzer, checks the light intensity of

the optical system, shuts down the analyzer and then requests the technician to remove the lamp holder again

and replace it again turning it 180º on the axis of the lamp. If the temperature of the lamp holder is high, wait until

it cools down or use pincers to hold it. The program starts up the analyzer again, measures the light intensity

of the optical system again, compares the light intensity in both possible positions and chooses the greatest

luminosity. If it is the current position, it tells the technician that the test is complete. If the best position were

the previous one, the program shuts down the analyzer and asks the technician to remove the lamp holder and

replace it, turning it 180º on the axis of the lamp, returning the lamp to its initial position. If the option selected

at the beginning was to Check the Lamp, the process is the same but without shutting down the analyzer at

the beginning.

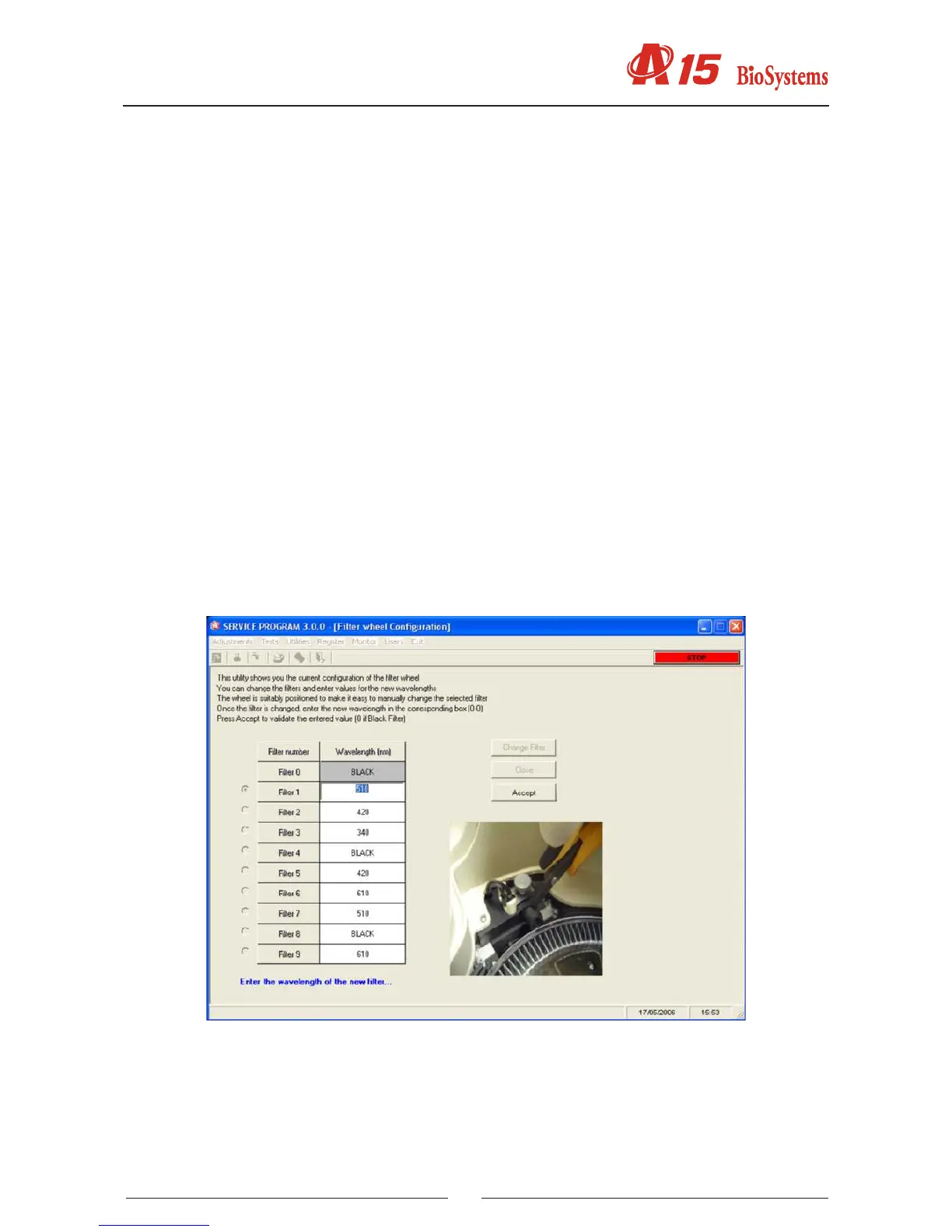

4.4.5. Conguration of the lter wheel

This screen enables the modication of the analyzer lter wheel. The wheel has 10 positions. Position 0 must

always contain a covered lter so that the analyzer can perform the darkness adjustment. Positions 1 to 9 can

be used for optical lters. All the positions of the wheel must be occupied for it to work correctly. The positions

that do not contain an optical lter must be occupied by a covered lter. The analyzer includes as standard 8

optical lters in positions 1 to 8 and two covered lters in positions 0 to 9. If one of the lters is to be changed,

select the desired position of the wheel and press the Change Filter button. The analyzer automatically posi-

tions the lter wheel appropriately so that the technician can change the lter through the window of the optical

system. Next, if it is different, introduce the wavelength of the new lter that has been installed. If the lter is

covered, introduce value 0. On closing the screen, the analyzer asks if the lters have actually been physically

changed and a series of warnings are given to the technician telling him he must bear in mind whether or not

he has changed a lter.

4.4.6. Demonstration mode

On pressing the Start button, the analyzer activates some of its mobile components, imitating functioning during

a work routine. The activated mechanical components are the operating arm, the reactions rotor and the lter

wheel. On pressing the Cancel button, the analyzer nishes the current cycle and returns to its rest position.

Loading...

Loading...