108 EM-ABS-01 for ACU 03/12

8.4.10 SSI: Sampling interval

SSI frequency encoders often use a samplin

rate in the millisecond ran

e. In order for

the evaluation in the device to work correctly, the samplin

rate of the SSI absolute

value encoder must be set up. If the samplin

rate of the encoder cannot be ad

usted,

use the next hi

her, available settin

. The parameter value is ad

usted as a multiplie

of 125 us.

Note: Not all steps from 0 to 240 are available. The selection list limits the

available options to reasonable settings.

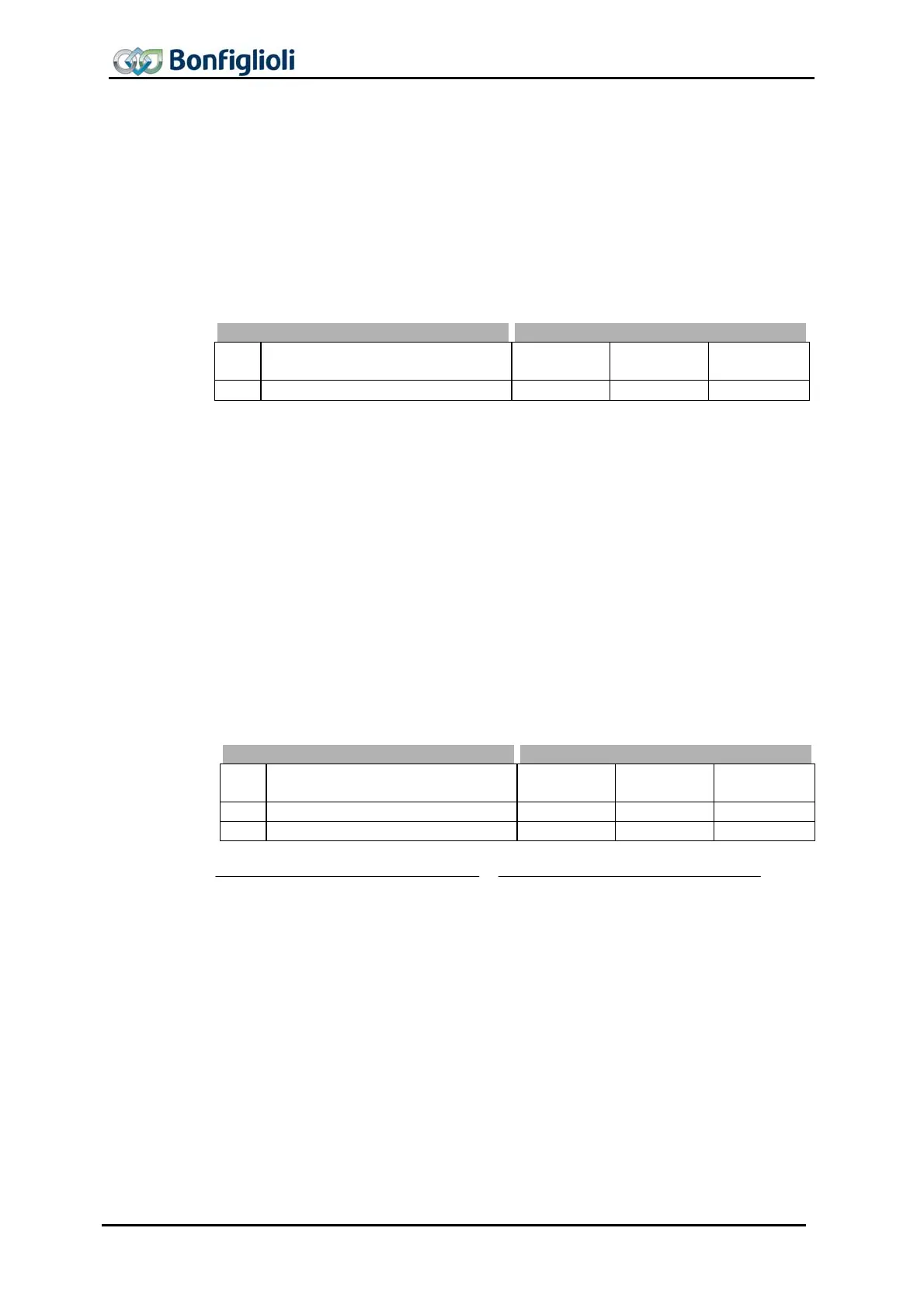

Parameters Settings

No. Description Min. Max. Factory set-

ting

1268 SSI: Sampling interval 0 240 0

Attention: For a

ood positionin

behavior, the samplin

rate is to be less than 1

ms.

In the case of hi

her samplin

rates, unwanted hi

h system vibration o

even machine dama

e may occur, if the speed and position controller are

configured improperly.

In the case of hi

h samplin

rates (> 2 ms), reduce the dynamics of the

system via the speed controller and the position controller.

Positionin

accuracy will be lower in the case of hi

h samplin

rates. For

precise applications, use encoders with low sampling rates.

8.4.11 Gear factor speed sensor 2

If the speed sensor is coupled to the motor via one or more

ears, the transmission

ratio between the motor and the encoder must be configured via

C2 Gear Facto

umerato

513 and EC2 Gear Factor Denominator 514.

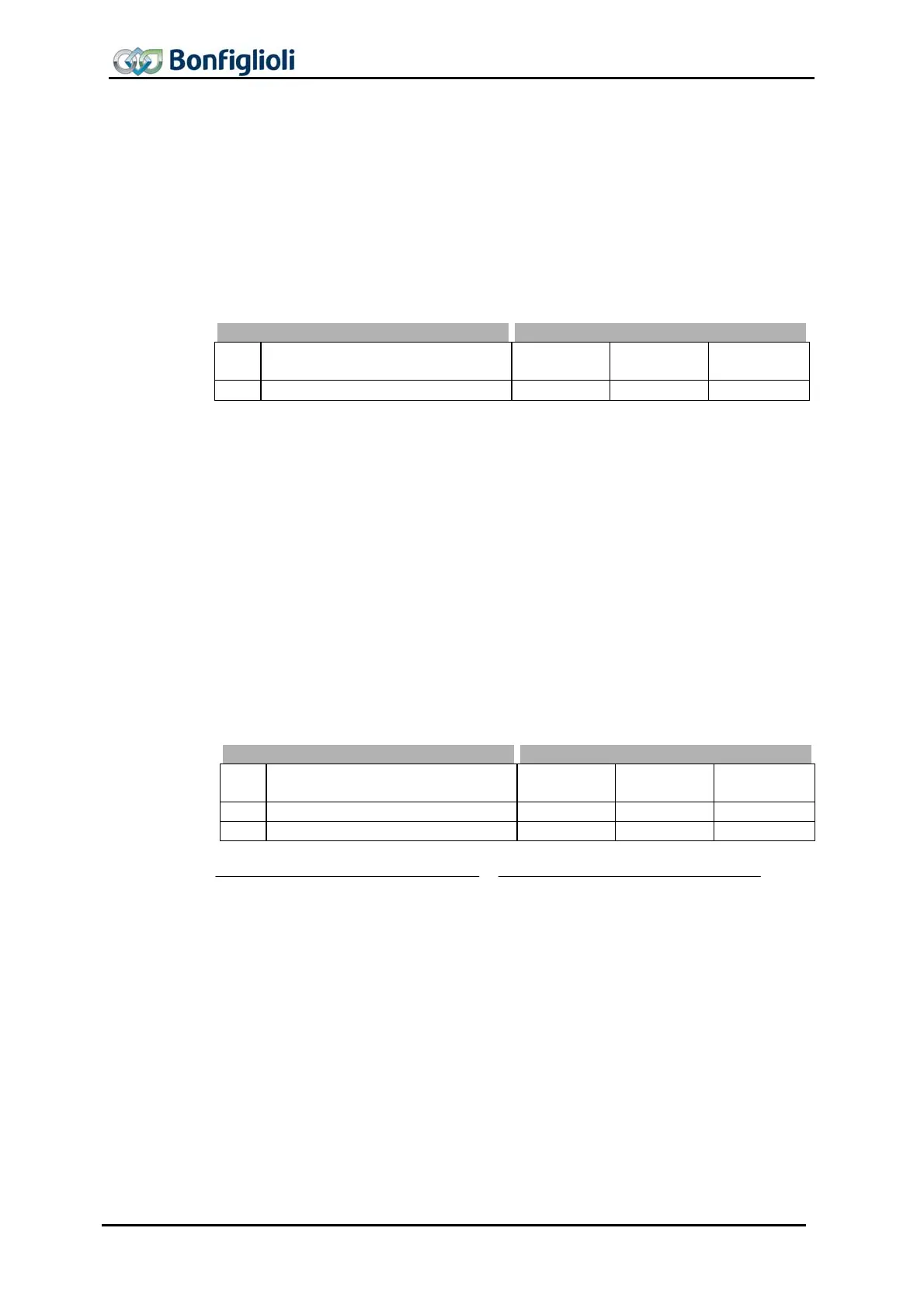

Parameters Settings

No. Description Min. Max. Factory set-

ting

513 EC2 Gear Factor Numerator -300.00 300.00 1.00

514 EC2 Gear Factor Denominator 0.01 300.00 1.00

514

513

shaft encoder EC2 the of sRevolution

shaftMotor the of sRevolution

rDenominato Factor Gear 2 EC

Numerator Factor Gear 2 EC

=

Note:

Gear factors EC2 Gear Factor Numerator 513 and

C2 Gear Facto

enominato

514 must always be referred to the motor.

Note: In the case of linear encoders, this value must be set according to chap-

ter

6.6.

Loading...

Loading...