03/12 EM-ABS-01 for ACU 111

Parameters Settings

No. Description Min. Max. Factory set-

ting

1115 Feed constant 1 u/U 2

31

-1 u/U 65536 u/U

1116

Gear Box: Driving Shaft Revolu-

tions

1 65 535 1

1117 Gear Box: Motor Shaft Revolutions 1 65 535 1

For application encoders, a

ear transmission between the application encoder and

motor must be parameterized via a gear factor (see chapter

8.4.11 “Gear factor speed

sensor 2”).

he conversions between the different reference systems are done automatically, the

user sets the target values in user units referred to the distance.

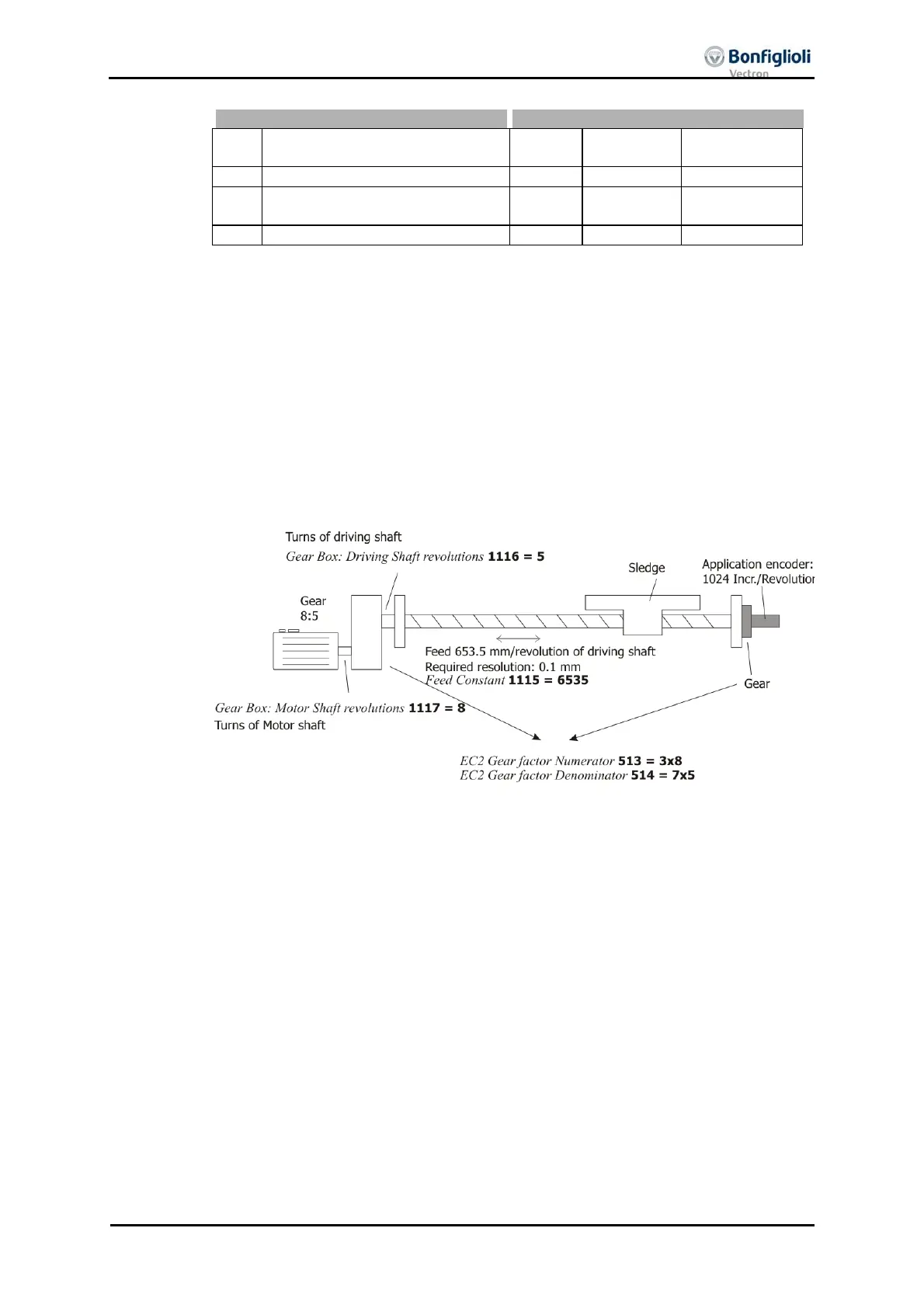

8.4.13.1 Example

For parameterization of a linear slide, the following properties are known:

Motor gear ratio: 8:5

pplication encoder

ear ratio: 7:3

Feed rate of linear axis: 635.5 mm/revolution of the output shaft

This results in the following parameterization:

eed constant 1115 = 6535 rev

Gear shaft turns 1116 = 5

Gear motor turns 1117 = 8

C2 Gear Factor Numerato

513 = 24

C2 Gear Factor Denominato

514 = 35

In order to move by 1 mm, a positioning order of 10 u must be executed.

Note: In the case of linear systems, the feed constant is typically specified in

the data sheet. If this value is unknown, it must be determined empirical-

ly. For empirical determination of the feed constant, refer to application

manual “Positioning”.

Loading...

Loading...