1 689 975 233 2018-05-08| Robert Bosch GmbH

Variant overview | EPS 708 | 7 en

3. Variant overview

3.1 Voltage variants

Test bench Mains voltage Color

0 683 708 001 400 V - 500 V without chiller

0 683 708 020 400 V - 500 V with chiller

0 683 708 002 200 V - 240 V without chiller

0 683 708 021 200 V - 240 V with chiller

3.2 Control unit variants

The control unit variant can be read on the name plate

of the control unit (see Fig. 1)

Fig. 1: Control unit name plate

Date of manufacture (FD) Control unit variant

FD 2011-04 to FD 2011-06 NN

from FD 2011-06 XP

3.3 Sealing ring variants

Sealing rings of different materials are used for sealing

on the pressure regulating valve block (Fig. 2) and sole-

noid valve block (Fig. 3). The correct tightening torque

must be used based on the material of the sealing ring

(fiber or copper); otherwise, the joint will not be tight

or the sealing ring will be damaged. Fiber sealing rings

or copper sealing rings were used at the following loca-

tions (see arrows).

Fig. 2: pressure control valve block

458863-81_Pal

Fig. 3: Solenoid valve block

i Always use new sealing rings when replacing com-

ponents. The new sealing rings must be made from

the same material as the previously installed sealing

rings. Otherwise, a tight connection cannot be

assured.

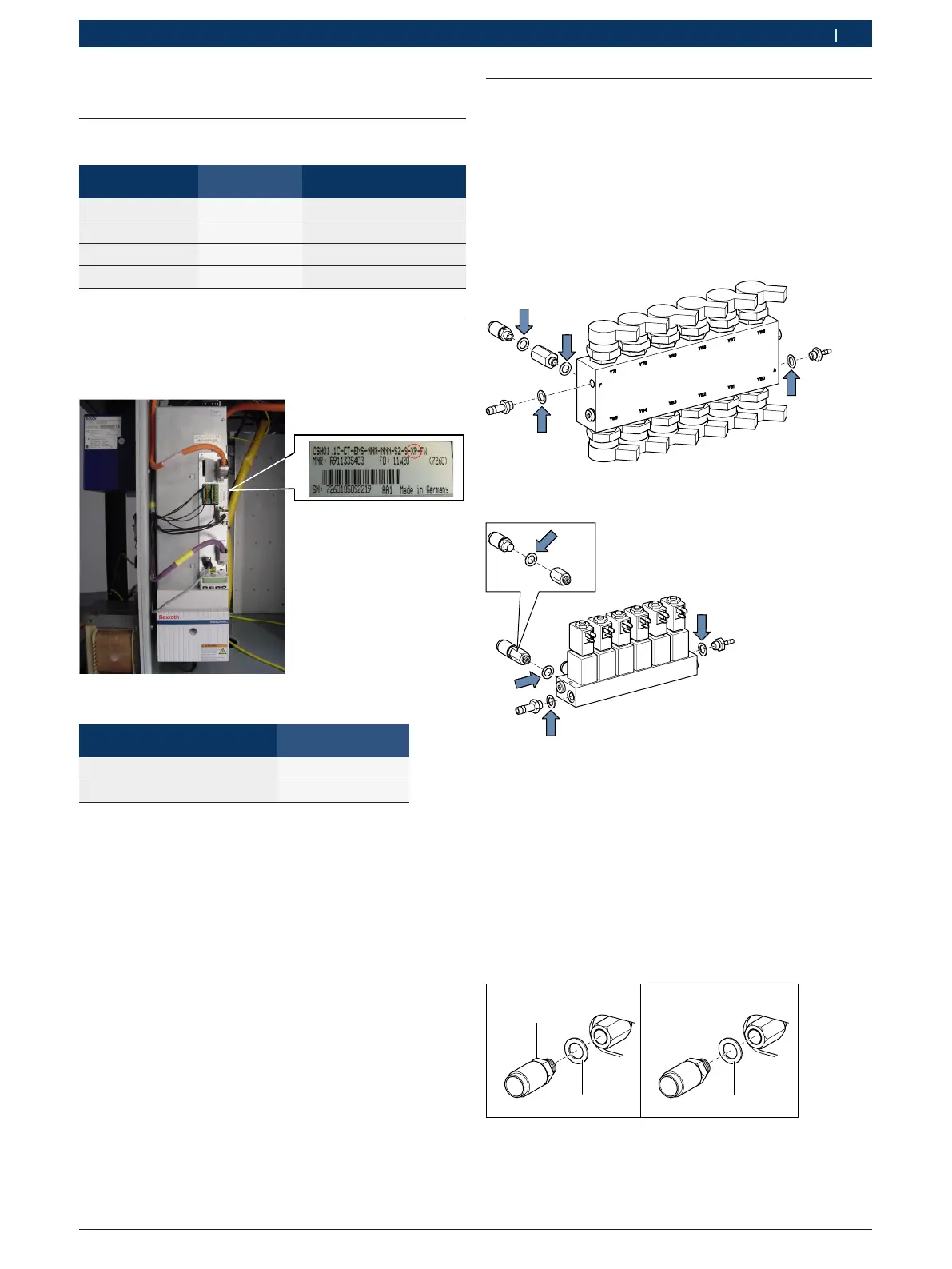

Use the following tightening torques based on the mate-

rial of the sealing ring:

4588863-77_Pal

max. 6 Nm

15 +2 Nm

1

2

Fig. 4: Tightening torques

1 Fiber sealing ring

2 Copper sealing ring

Loading...

Loading...