1 689 975 233 2018-05-08| Robert Bosch GmbH

Calibrating the high-pressure rail | EPS 708 | 89 en

10.1.9 Checking measured values

1. Open the "Measurement functions" menu with

<F7>.

2. Select the "Automatic On/Off" menu item and acti-

vate the automatic function with <F12>.

The automatic symbol flashes in the operating

status display.

The system reaches the set values and the wai-

ting/measurement time commences. After the

waiting/measuring time has elapsed, the system

software automatically changes to the next test

step.

3. In the event of the message "System stop! No

further test steps available! Results

with F12 >> ", press <F12> to open the log.

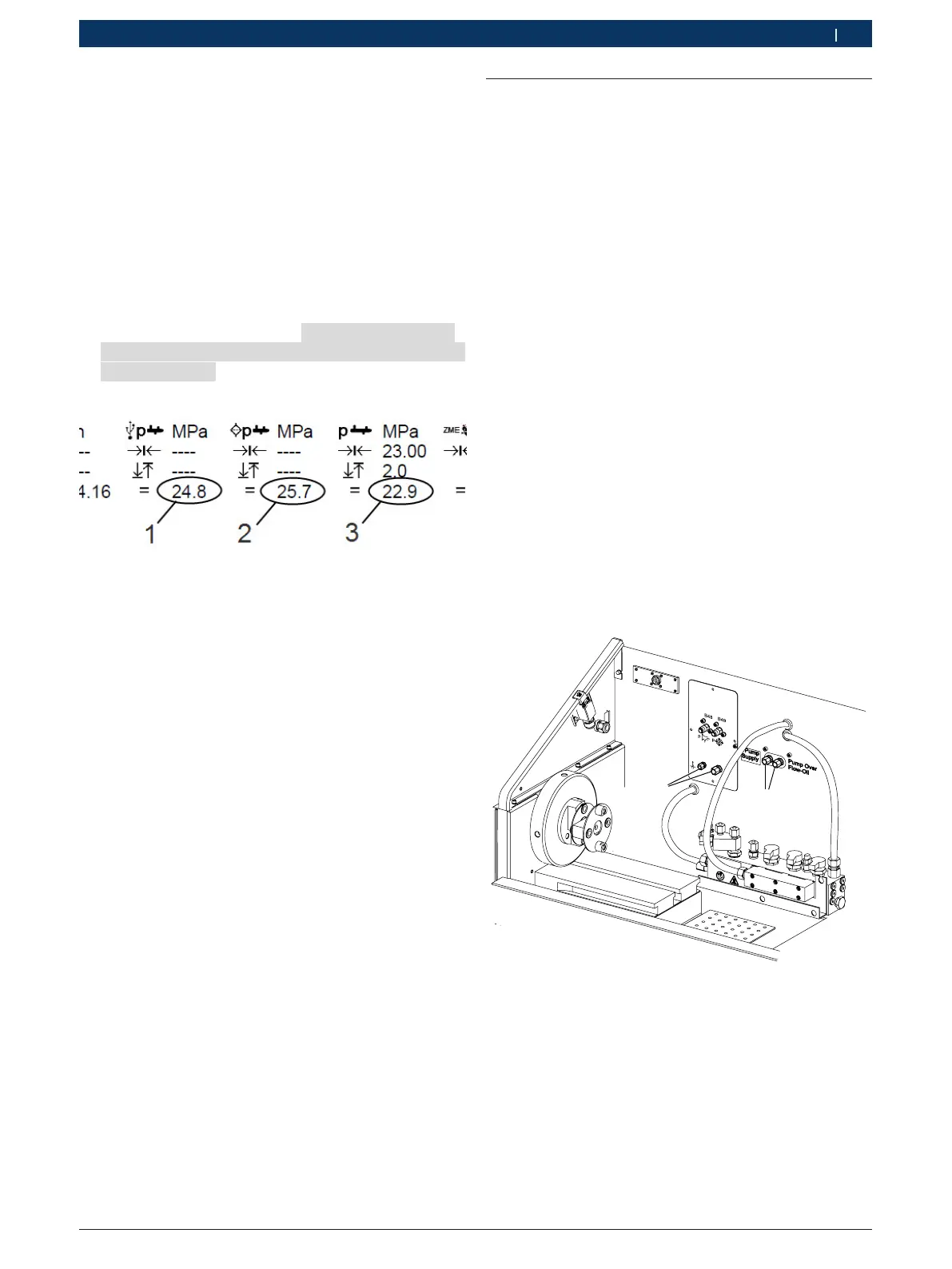

Fig. 156: Excerpt from the test log

1 Measured value for External pressure value

2 Measured value for Test bench pressure value upstream of filter

3 Measured value for Test bench pressure value.

4. At all verification points, compare the measured

values Test bench pressure value and Test bench

pressure value upstream of filter with External

pressure value (see Fig. 156). The difference in

pressure must not exceed 0.5MPa.

Calibration must be repeated if the pressure diffe-

rence is > 0.5 MPa.

10.1.10 Ending calibration

1. Exit the "Result printout" dialog box by pressing <Esc>.

2. In the "Injection component test main menu" start

screen, select <F7>.

You are asked to enter a password.

3. Enter the password in the input line: 1958

4. Confirm your entry with <F12>.

5. Select the Calibration >> Rail pressure sensor

menu option.

6. Select <F6> "Calib. check".

7. Continue with <F12>.

8. Exit the menu with <Esc>.

The system software reinitializes the devices.

9. Remove the USB connecting cable of the pressure

sensor from the PC.

10. Remove the pressure sensor from the high-pressure

rail.

11. Use a dummy plug to seal the connection for the

CRI846 distributor rail on the high-pressure rail.

12. Remove the common rail pump.

" Pressure sensor calibration is complete.

10.2 Performing the zero point adjust-

ment of pressure sensors

i After pressure sensors B1, B4, B5, B6 and B19 have

been replaced (only with lubricating-oil supply unit)

in the low-pressure circuit, a zero point adjustment

must be performed. For this, the pressure sensors

must be exposed to ambient pressure. All pressure

sensors are adjusted simultaneously.

1. Switch on the EPS 708 at the master switch.

2. Start the software EPS945.

The software performs initialization

3. In the "Injection component test main menu" start

screen, select <F7>.

A password request appears.

4. Enter the password in the input line: 1958

5. Confirm your entry with <F12>.

6. Select menu item "Calibration >> EPS708".

7. Continue with <F12>.

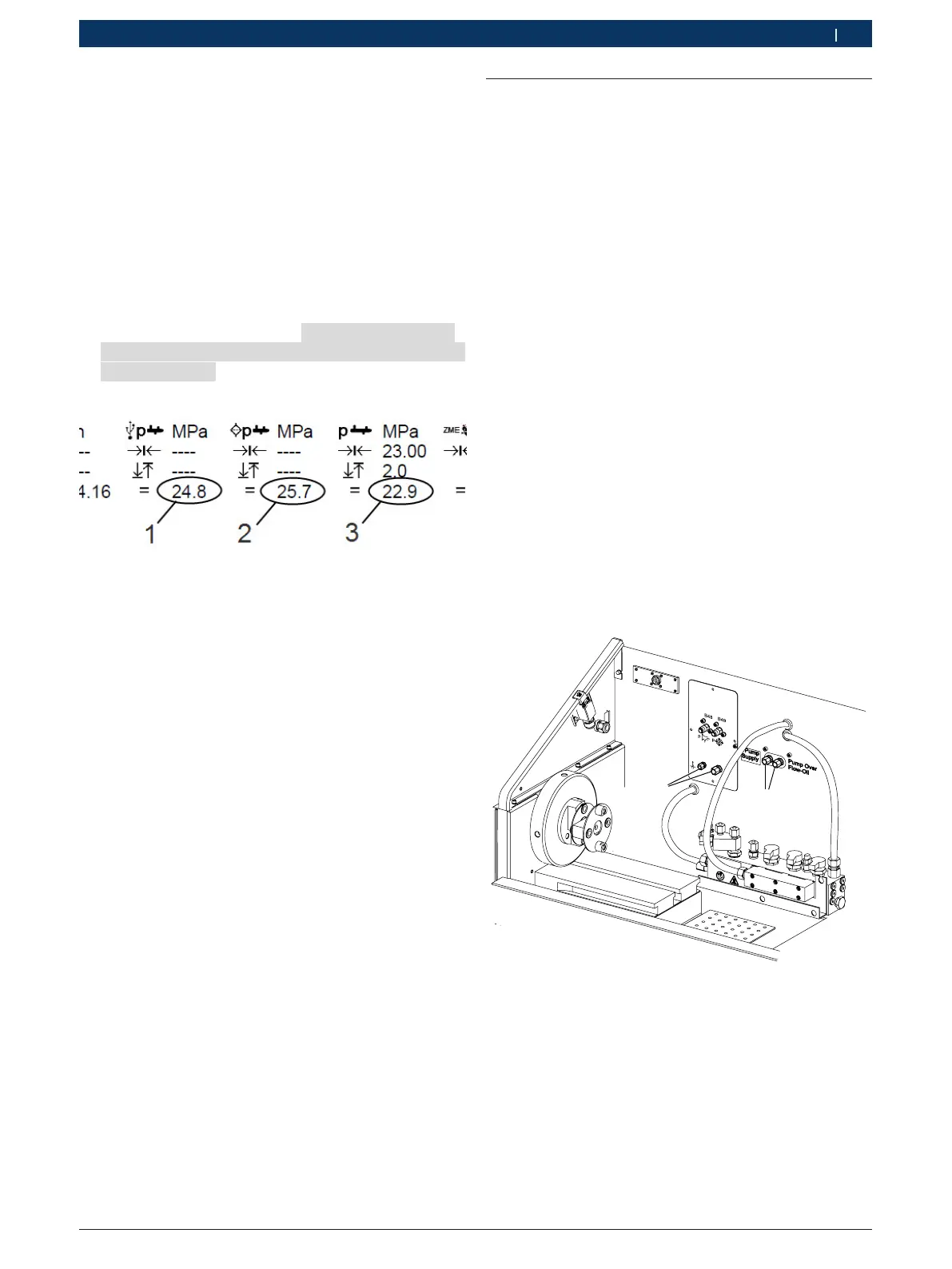

8. In the test area of EPS 708, remove the hose assem-

blies from both test oil connections

(Fig. 157, item1). The test connections

(Fig. 157, item 1) must be open.

9. Remove the hose assemblies from both lubricating

oil connections (Fig. 157, item 2). The lubricating oil

connections (Fig. 157, item 2) must be open.

X22

1

2

Fig. 157: EPS 708 Test area

10. Press <F2>.

11. Confirm query with <F4> and accept selection with

<F12>.

All print values are reset to zero.

12. Exit the window by pressing Esc.

13. Exit the configuration menu by pressing Esc twice.

Loading...

Loading...