330

GEARCASE

BEARING AND SEAL INSTALLATION

Apply Needle Bearing grease to the needle bear-

ings and insert them into the bearing case (except

“S” Type).

Place the bearing on the installer tool with the let-

tered side of the bearing facing the top of the

gearcase. Use Needle Bearing grease to hold the

bearing on the tool.

IMPORTANT: The pinion bearing is tapered so

that, when installed correctly, its shape compen-

sates for stresses in the gearcase and allows full

bearing contact. Whenever a gearcase is disas-

sembled, the pinion bearing should be checked to

ensure that it has been installed with the lettering

facing up.

Insert the tool with the bearing into the gearcase.

Drive the bearing into the gearcase until the

washer on the tool contacts the spacer.

Remove the tool.

Position new O-ring on the pinion bearing retain-

ing screw. Apply Gasket Sealing Compound to O-

ring. Apply Nut Lock to screw threads. Install the

screw and torque to 60 to 84 in. lbs. (7 to 9.5

N·m).

Driveshaft Bearing Housing

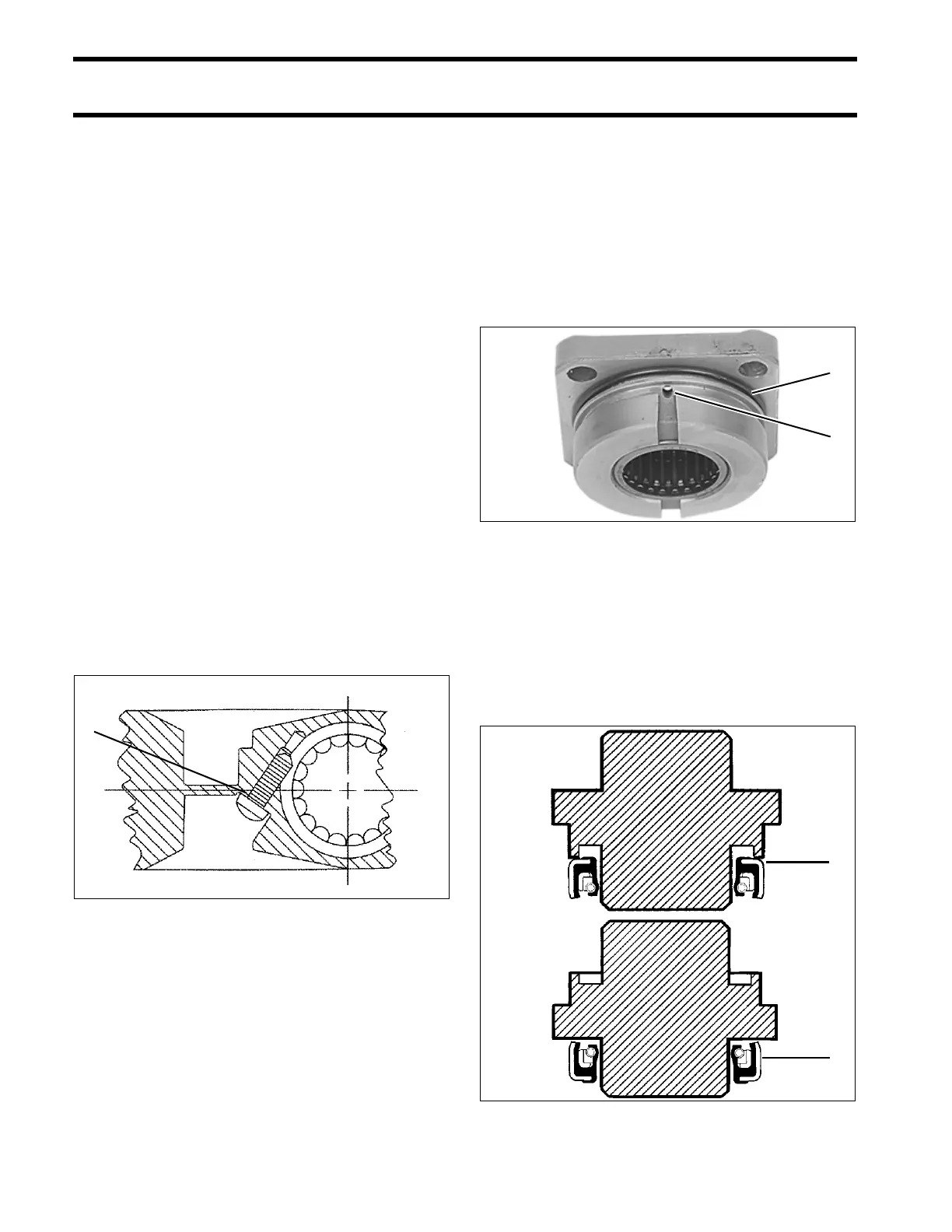

Lightly apply Gasket Sealing Compound to a new

O-ring. Install the O-ring in top groove of the bear-

ing housing. Do not allow sealant in oil passage.

IMPORTANT: Do not install the O-ring in the

bearing housing’s bottom groove. The bottom

groove is an oil passage. Gearcase damage could

result.

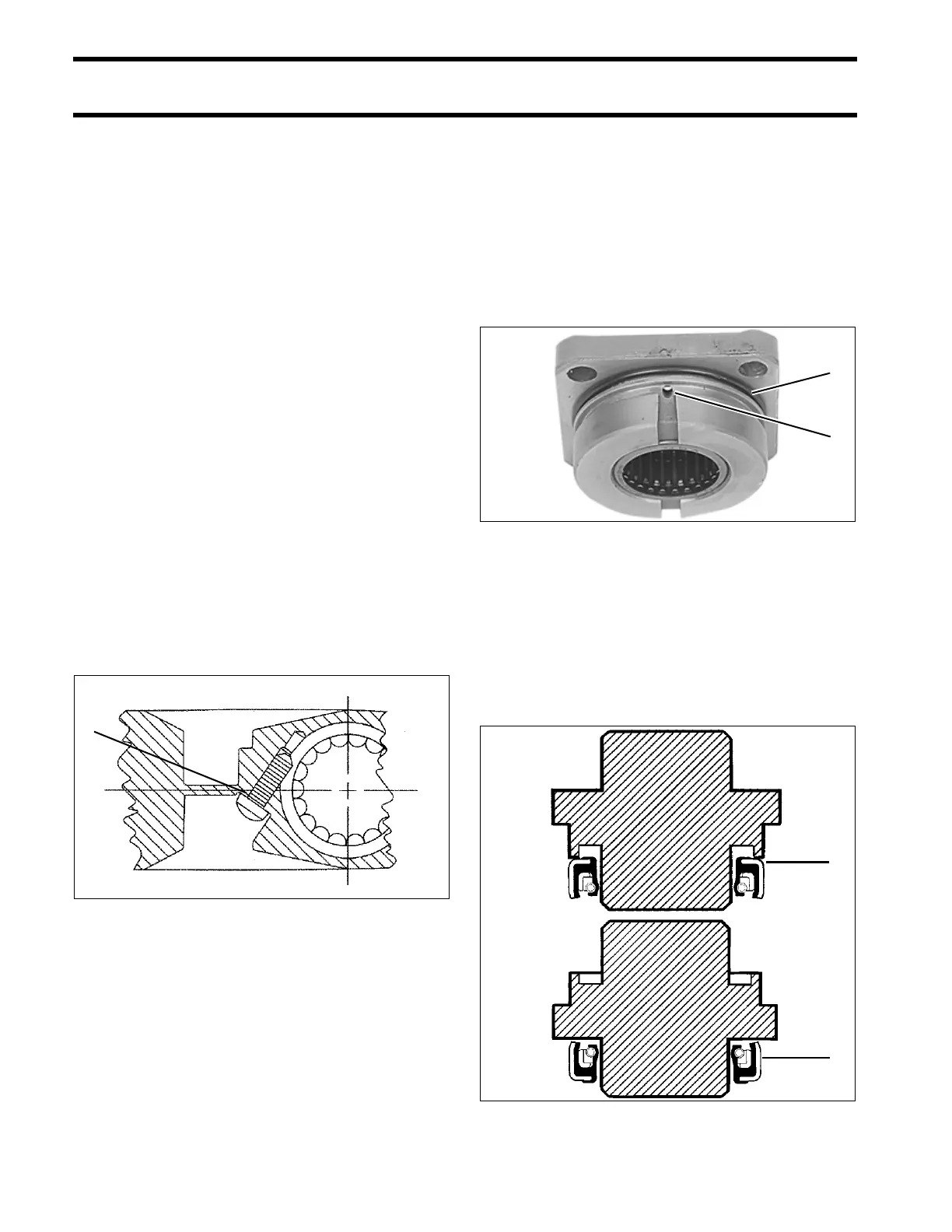

Install new seals back to back in bearing housing

using Seal Installation Tool, P/N 330268. Apply

Gasket Sealing Compound to metal casings of the

seals before installing. Install inner seal with lip

facing toward bearing housing, then the outer seal

with lip facing away from bearing housing. Apply

Triple-Guard grease to seal lips.

1. O-ring DRC7416

1

1. O-ring (top groove)

2. Oil passage

14156

1. Inner seal

2. Outer seal

DR2061

DR2062

1

2

1

2

Loading...

Loading...