376

TRIM AND TILT

SERVICING – THREE PISTON SYSTEM

SERVICING – THREE

PISTON SYSTEM

Disassembly

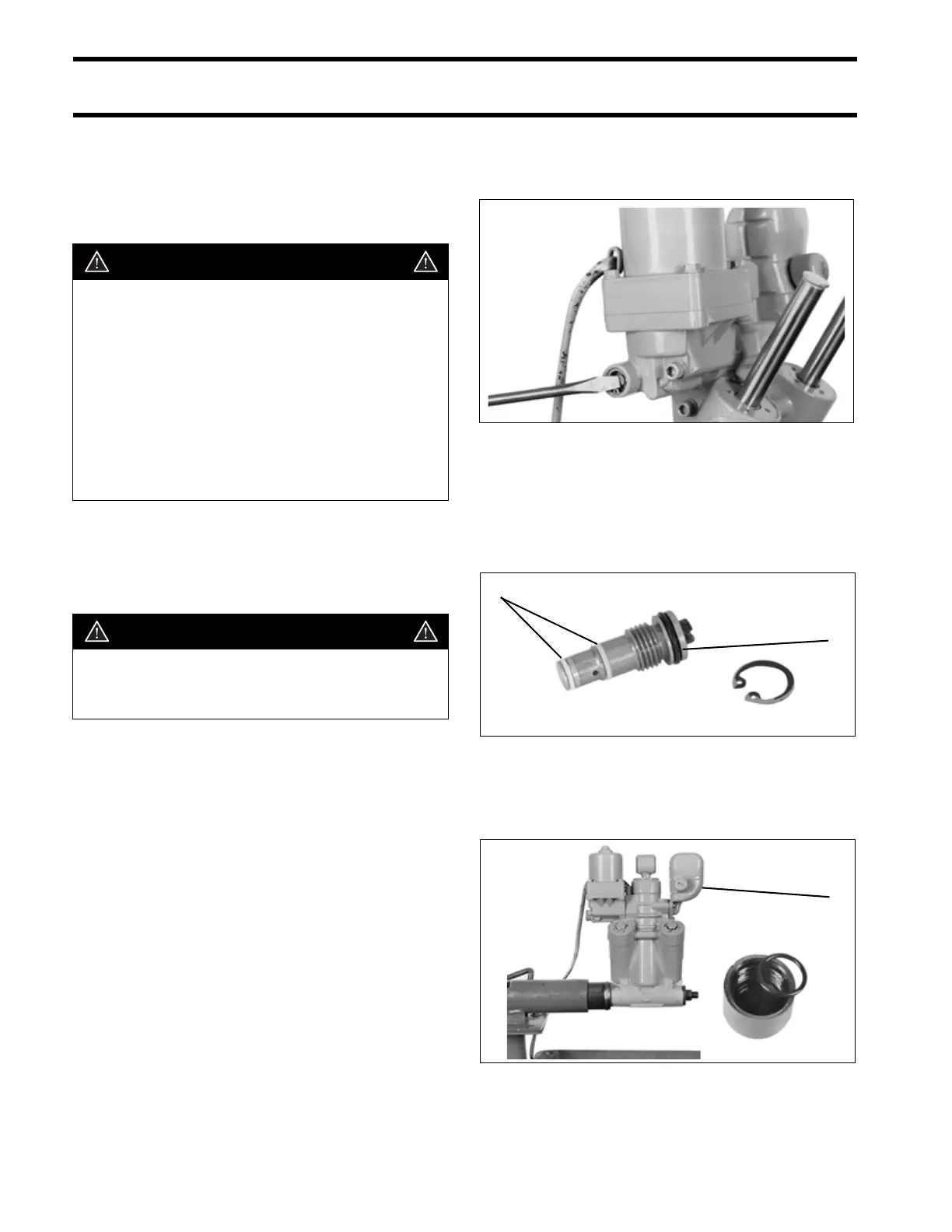

Thoroughly clean the unit before disassembling.

Scrub all outside surfaces with a stiff brush and

hot, soapy water to prevent surface dirt from con-

taminating internal parts.

Always use a lint free shop cloth when handling

power trim/tilt components.

If painting the unit is required, paint it after it is

completely assembled. Painting of individual com-

ponents may cause flakes of paint to enter the

hydraulic passages during assembly. Tape the

trim/tilt piston rods before painting.

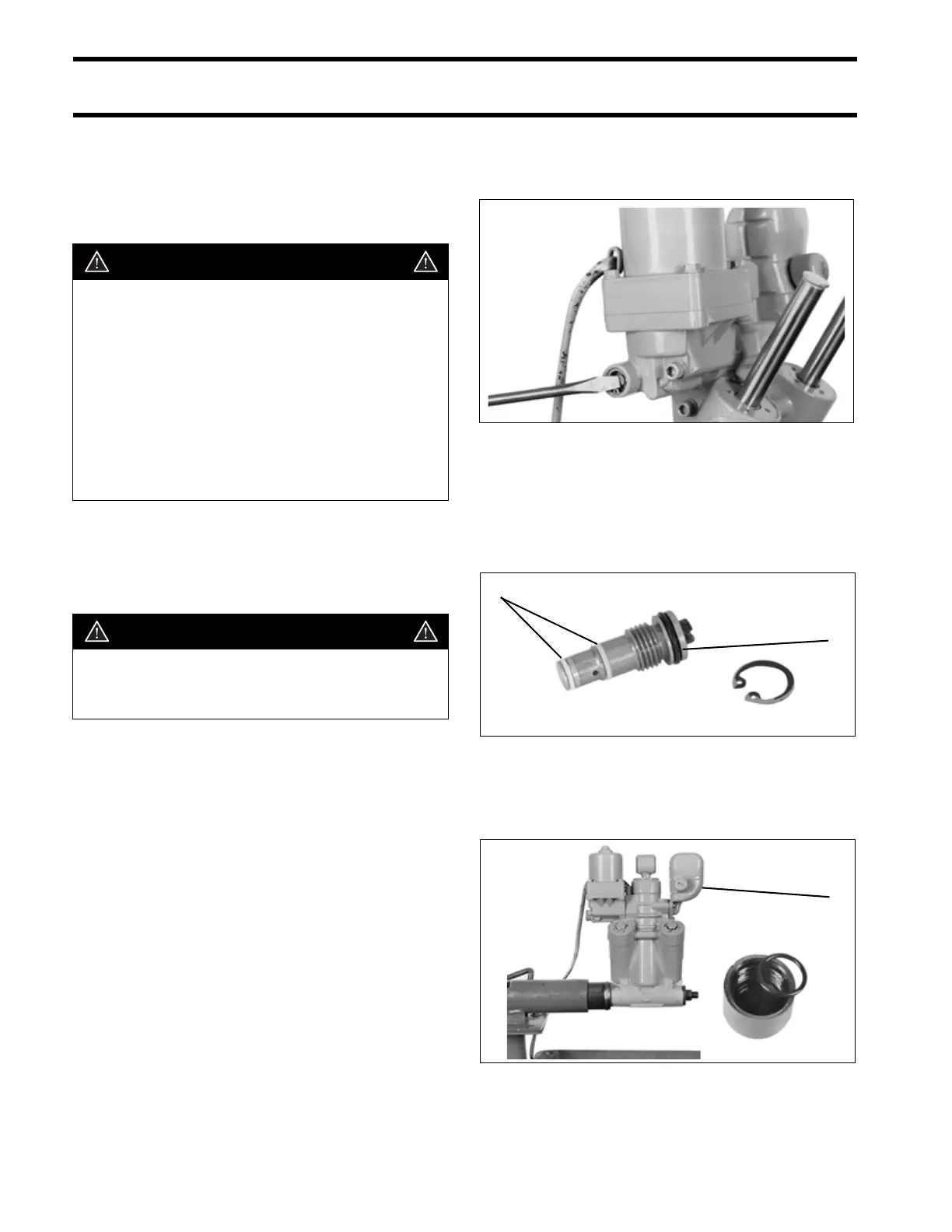

Screw the manual release valve in. Remove the

retaining ring using retaining ring pliers. Remove

the manual release valve.

Inspect O-ring and two plastic split rings on the

manual release valve for nicks and cuts. Inspect

tip of valve for damage. The two plastic split rings

are not available separately. If rings are damaged,

replace the manual release valve.

Remove reservoir cap and drain the fluid into a

container. Inspect the O-ring in the cap.

WARNING

Before removing the manual release valve,

operate the unit to the full UP position,

then run the unit down momentarily and

loosen the reservoir cap one full turn.

To avoid personal injury, always wear eye

protection when servicing the hydraulic

unit. Since there might be significant

residual pressure behind some compo-

nents, cover each component with a shop

cloth as you remove it.

CAUTION

Do not apply heat to the cylinder body or

cylinders. Excessive heat can cause high

pressure leaks or failure of parts.

41739

1. O-ring

2. Plastic split rings

22863

1. Reservoir cap 41736

41751

1

2

1

Loading...

Loading...