340

GEARCASE

ASSEMBLY

Propeller Shaft Bearing

Housing and Gear Installation

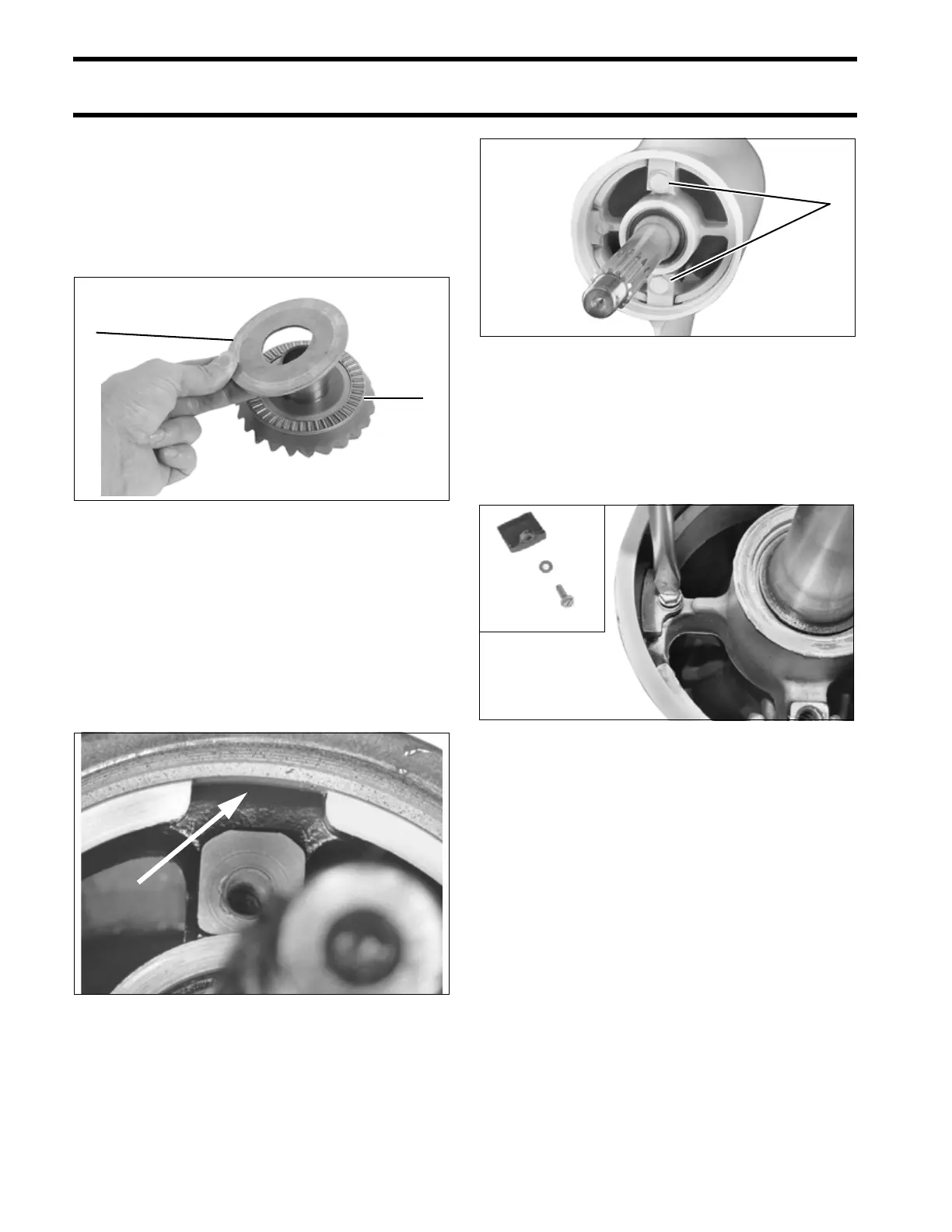

Oil and install thrust bearing and thrust washer on

hub of reverse gear. Slide the reverse gear

assembly onto the propeller shaft until it engages

the pinion gear.

Lightly apply Gasket Sealing Compound to a new

bearing housing O-ring. Install O-ring in groove in

the housing.

Install housing into gearcase, aligning screw holes

with retainer slots in gearcase.

Housing must be completely seated to install

retainer tabs.

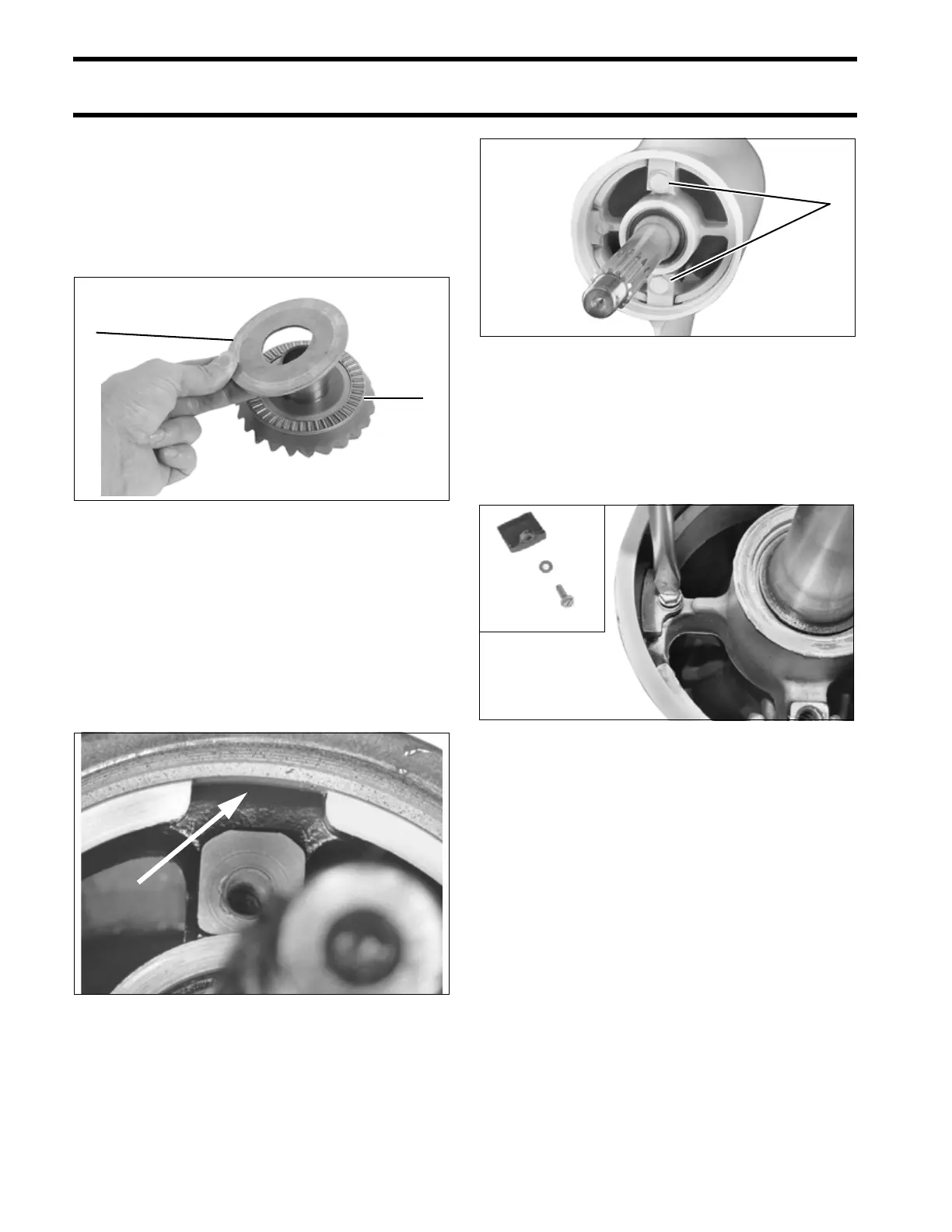

Install two retainers, washers and screws. Apply

Ultra Lock to threads and torque screws 18 to 20

ft. lbs. (24 to 27 N·m).

“O,” “L,” AND “M” TYPE GEARCASES

Loosen retainer screws 1/4 turn.

Install wedge, screw, and washer. Apply Ultra

Lock to threads and torque screw 15 to 20 in. lbs.

(1.7 to 2.3 N·m).

Re-torque two retainer screws to 18 to 20 ft. lbs.

(24 to 27 N·m).

Confirm that torque on the wedge screw is 15 to

20 in. lbs. (1.7 to 2.3 N·m).

To complete gearcase assembly, refer to:

• LEAK TEST on p. 308

• WATER PUMP on p. 311

• SHIFT ROD ADJUSTMENT on p. 314

• REMOVAL AND INSTALLATION on p. 308

• LUBRICANT on p. 307

• Propeller Hardware Installation on p. 74

• Trim Tab Adjustment on p. 77

During break-in period of a reassembled gear-

case, change the gearcase lubricant between 10

to 20 hours of operation.

1. Thrust bearing

2. Thrust washer

DSC02295

Retainer Tab Notch 50106a

1

2

1. Retainer tab screws 001989

DSM02291

DSC02361

1

Loading...

Loading...