157

ELECTRICAL AND IGNITION

TIMING ADJUSTMENTS

6

Install the electrical harness base and secure with

four screws. Torque screws to 60 to 84 in. lbs (7 to

9.5 N·m).

Reconnect the stator connector, two port side trim

system connectors, port engine temperature sen-

sor, and the port ground terminal.

Reconnect the crankshaft position sensor, throttle

position sensor, air temperature sensor, and oil

pump electrical connectors.

Install the EMM. Refer to EMM SERVICING on

p. 153.

IMPORTANT: Perform the timing verification

procedure after flywheel removal or replacement.

Refer to TIMING ADJUSTMENTS on p. 157.

TIMING ADJUSTMENTS

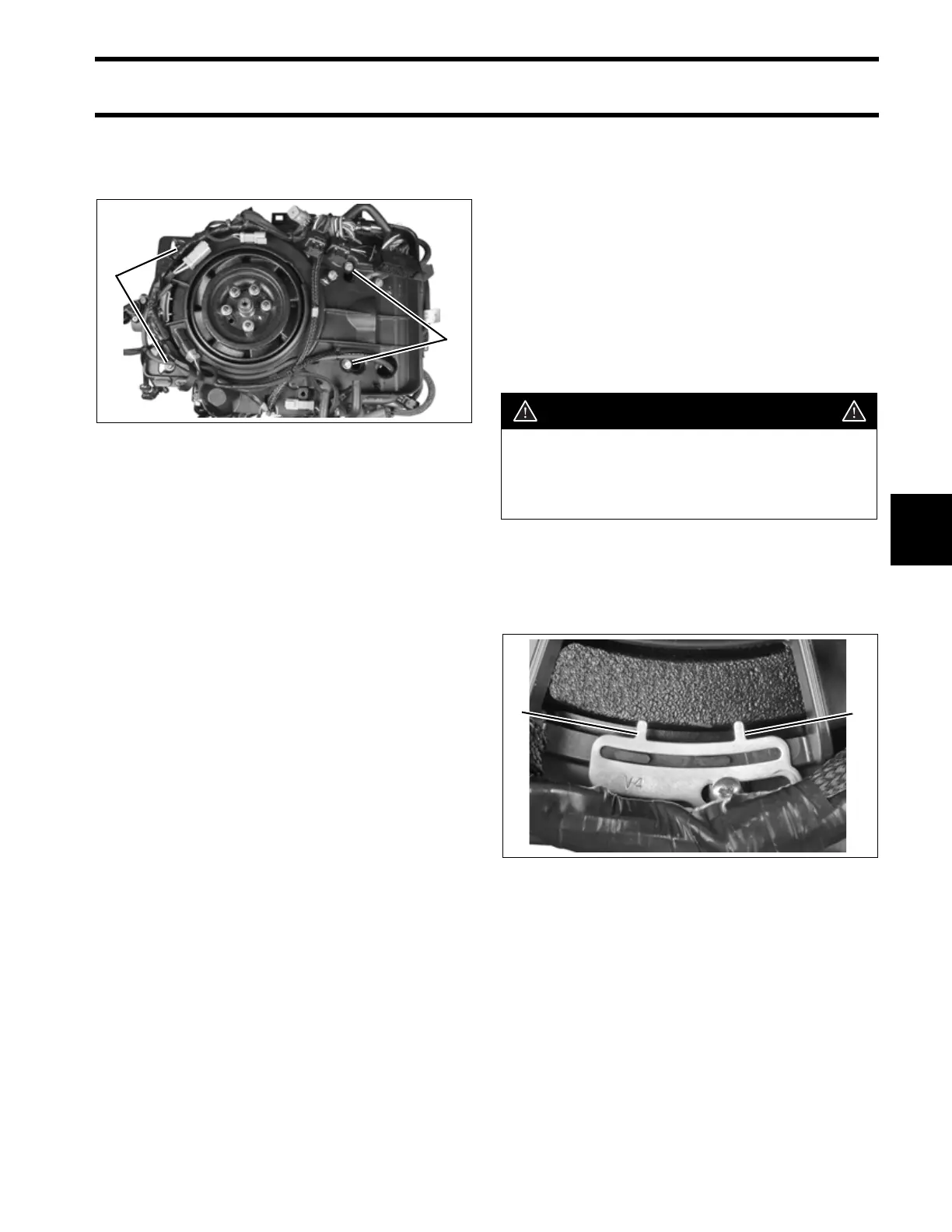

Timing Pointer

The timing pointer must be adjusted to indicate

“top dead center” (TDC) of the number 1 piston.

This reference to the position of the number 1 pis-

ton is used to synchronize the electronic timing

controlled by the EMM with the mechanical posi-

tion of the number 1 piston. Use the Evinrude

Diagnostics Software program to verify and adjust

timing. Refer to the software’s “Help Info” for out-

board timing verification procedures.

IMPORTANT: The pointer on these models has

two indicator points. The point labeled “V4” is

used for 60° V4 models. The unlabeled point is

used for 60° V6 models.

Turn the key switch OFF and disconnect the bat-

tery cables at the battery.

Remove spark plugs.

1. Harness base screws 005378

1

1

WARNING

To prevent accidental starting while ser-

vicing, remove emergency stop lanyard

and disconnect the battery cables at the

battery.

1. V4 pointer

2. V6 pointer

005385

21

Loading...

Loading...