220

OILING SYSTEM

OILING SYSTEM TESTS

Oil Supply Vacuum Test

Remove the oil pick-up assembly from the oil tank.

Carefully remove the pickup filter and flush with a

mild solvent to remove any contamination. Rein-

stall filter.

Carefully remove the oil hose from the oil pickup

and remove the oil supply hose from the oil injec-

tion pump.

Use low pressure air to purge oil from hose.

Use Plug/Holder, P/N 329661, and clamp to plug

the pickup end of the hose.

Attach a vacuum tester to the outboard side of oil

supply hose and draw 7 in. Hg (24 kPa) vacuum

on the hose for at least five minutes. Repair or

replace any leaking components. Reinstall the oil

hose.

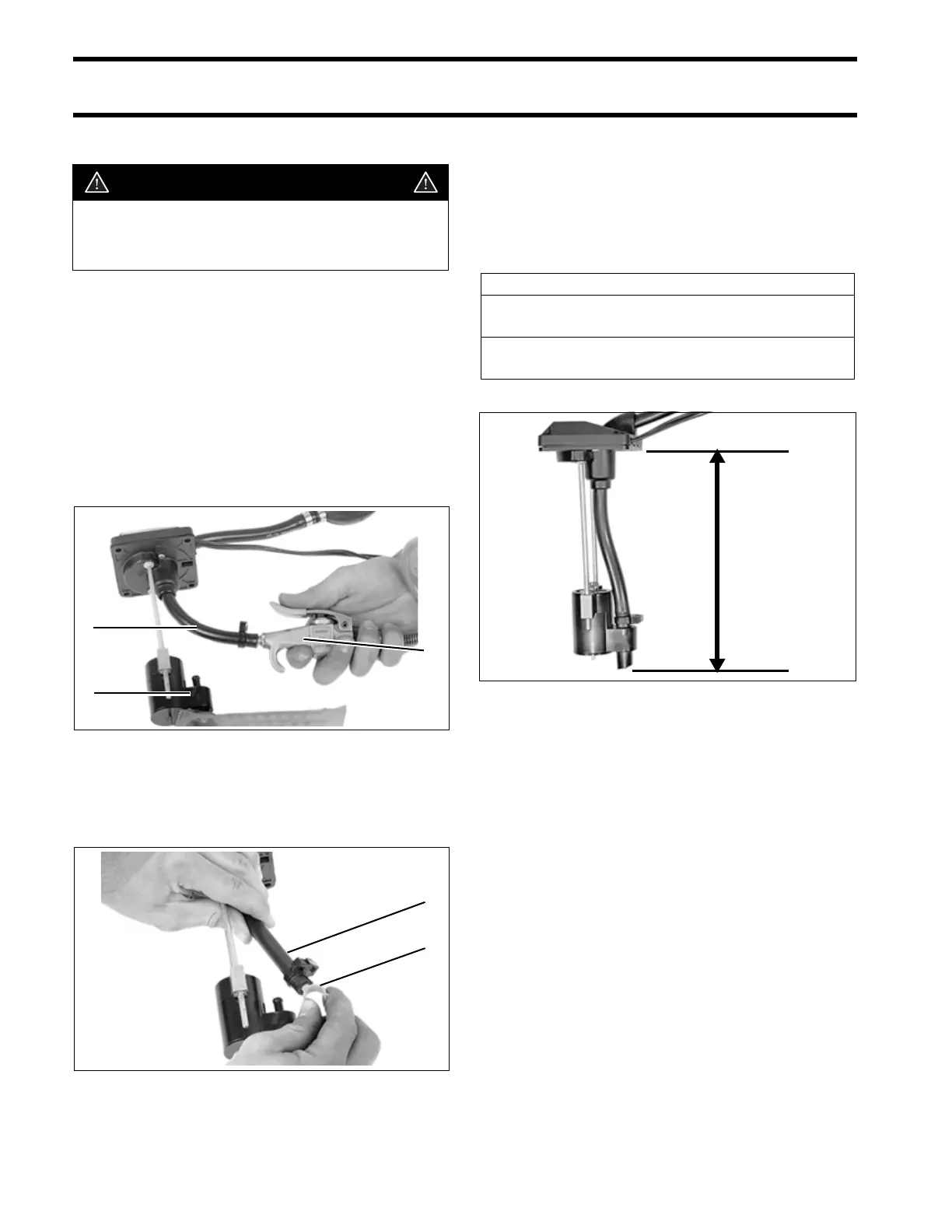

Check height of pickup assembly.

Position a new seal on oil tank and reinstall

pickup with filter into oil tank. Install and tighten

screws.

Oil Injection Pump Function Test

This test may be performed in two different ways:

Running Test

Remove oil distribution hose from fitting at cylin-

der block. Start and run the outboard at IDLE

speed and observe oil flow. Confirm that a small

amount of oil is discharged while injection pump is

activated

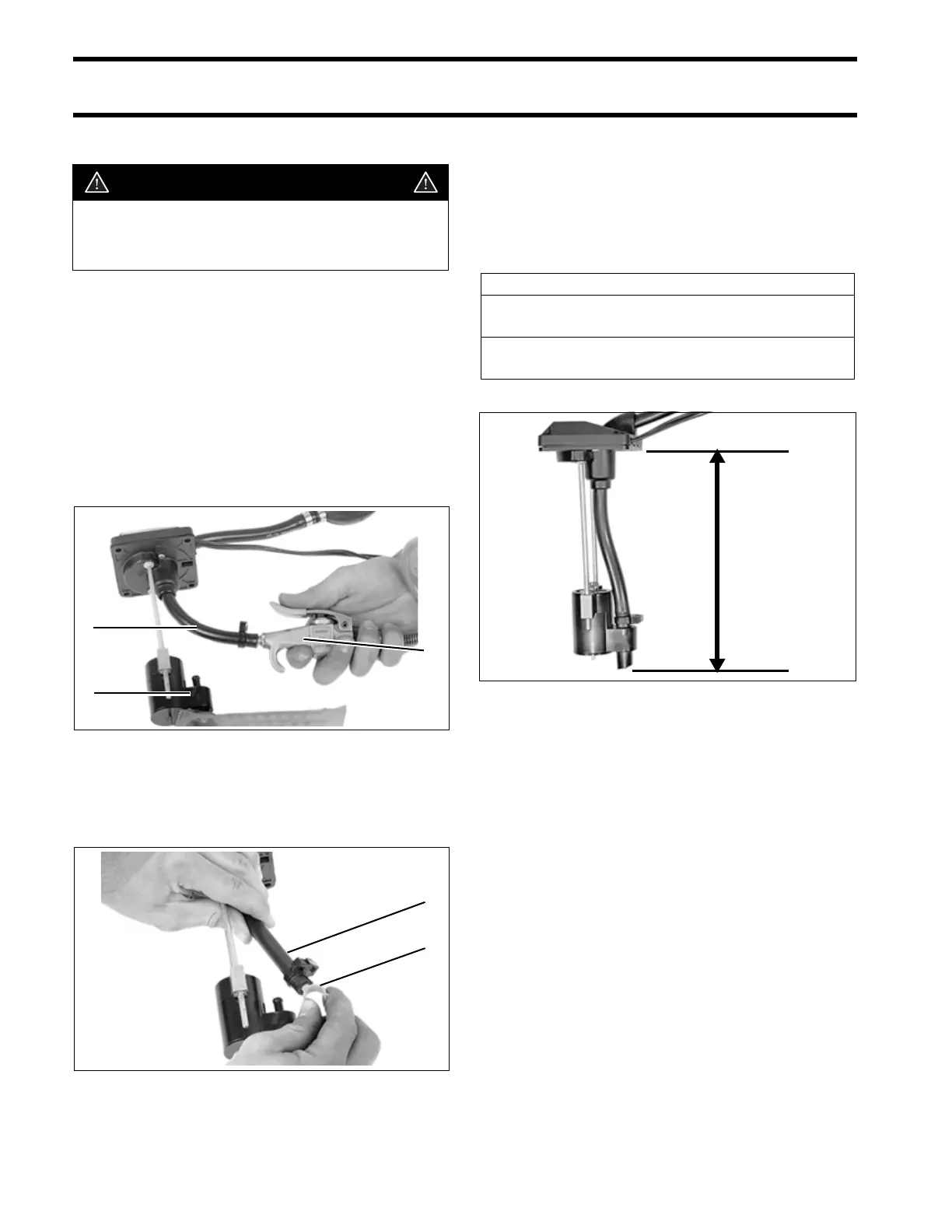

WARNING

Wear safety glasses to avoid personal

injury, and set compressed air pressure to

less than 25 psi (172 kPa).

1. Oil hose

2. Oil pickup

3. Low pressure air

12306

1. Plug/holder

2. Oil hose

12307

3

1

2

2

1

Pickup Assembly Height

1.8 gallon tank

6.84 to 6.96 in.

(174 to 177 mm)

3.0 gallon tank

8.74 to 8.86 in.

(222 to 225 mm)

Height of Oil Pickup Assembly COB5657A

Loading...

Loading...