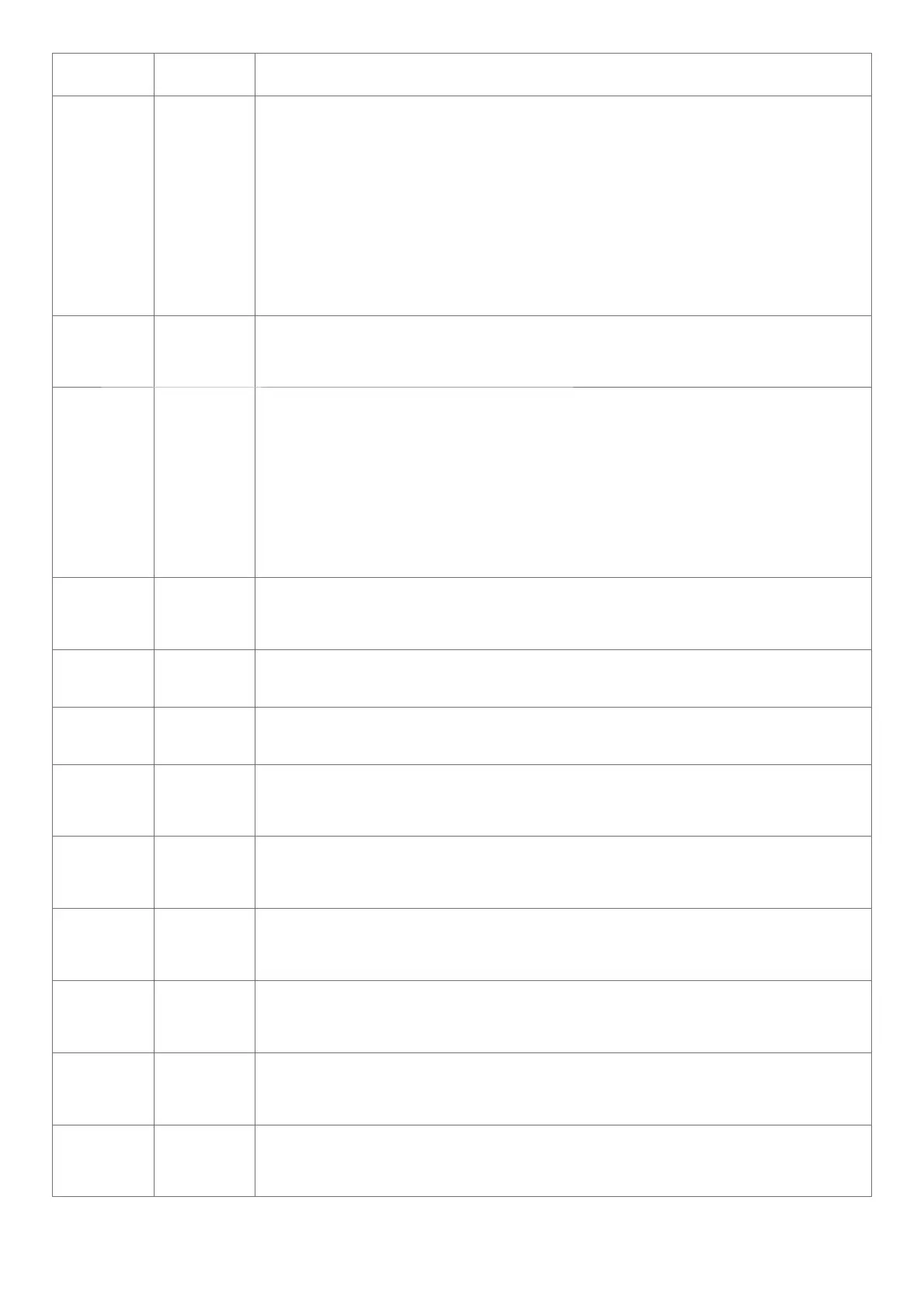

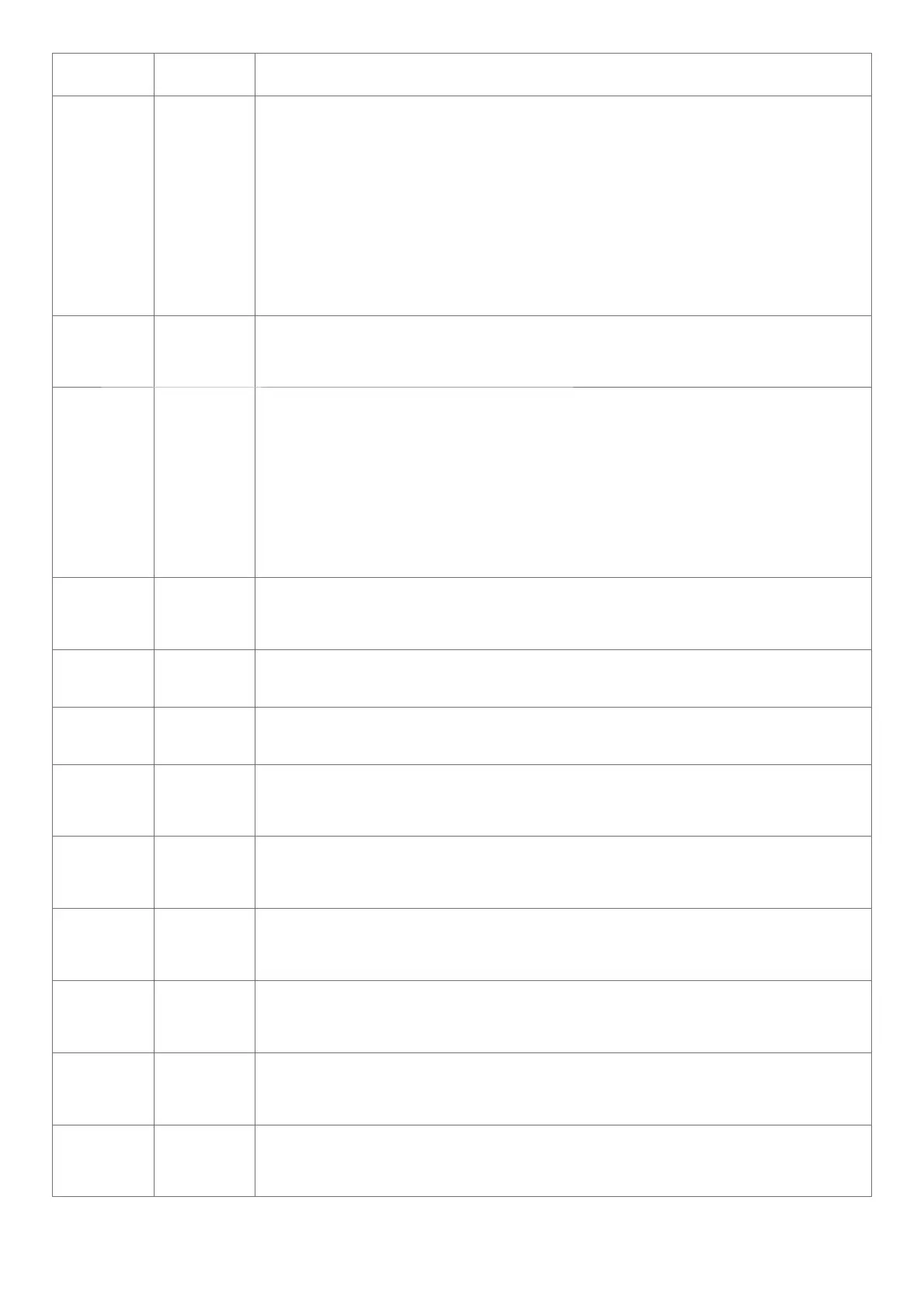

64

Error

condition

Error code Error description and possible diagnosis

Err E0.6

WATER COOLER MISSING

NON automatic reset error.

Check that the WATER COOLER SYSTEM - OBLIGATORY function is included within the

ADVANCED SETUP Menu / EQUIPMENT LAYOUT.

After this initial check you need to know that this error can only occur in the following cases:

• Water cooler system not connected to the welding machine.

• The welding machine does not recognise the water cooler system, even though it is connected

correctly.

• Water cooler system disconnected when the machine is operating normally.

Once the water cooler system has been reactivated, this error condition resets itself

automatically!

If the alarm occurs even when the WATER COOLER SYSTEM - OPTIONAL function is included in

the ADVANCED SETUP Menu / EQUIPMENT LAYOUT, call Technical Assistance Department

immediately.

Err E0.7

MOTOR FAULT

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on VISION S

CREEN ONLY in the event of a fault and NOT in the ERROR LOG Menu.

Err E0.8

WIRE FEEDER MISSING

NON automatic reset error.

Check that the WIRE FEEDER - OBLIGATORY function is included within the ADVANCED SETUP

Menu / EQUIPMENT LAYOUT.

After this initial check you need to know that this error can only occur in the following cases:

• Wire feeder not connected to the welding machine.

• The welding machine does not recognise the wire feeder, even though it is connected correctly.

• Wire feeder disconnected when the machine is operating normally.

Once the wire feeder has been reactivated, this error condition resets itself automatically!

If the alarm occurs even when the WIRE FEEDER - OPTIONAL function is included in the

ADVANCED SETUP Menu / EQUIPMENT LAYOUT, call Technical Assistance Department

immediately.

Err E0.9

CAN INTERNAL ERROR

Faulty communication between the generator and the feeder.

NON automatic reset error.

Error visible on VISION S

CREEN ONLY in the event of a fault and NOT in the ERROR LOG Menu.

Err T°C

THERMAL PROTECTION

The welding stops due to an excessively high temperature (thermostat activated).

Automatic reset error.

Err H20

COOLER PRESSURE

The fluid in the cooling system is at low pressure.

NON automatic reset error.

Err E1.0

CONFIG. FILE MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on VISION S

CREEN ONLY in the event of a fault and NOT in the ERROR LOG Menu.

Err E1.1

USER FILE MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on VISION S

CREEN ONLY in the event of a fault and NOT in the ERROR LOG Menu.

Err E1.2

TORCH FILE MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on VISION S

CREEN ONLY in the event of a fault and NOT in the ERROR LOG Menu.

Err E1.3

CALIBRATION FILE MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on VISION S

CREEN ONLY in the event of a fault and NOT in the ERROR LOG Menu.

Err E1.6

MMA DEFAULTS MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on VISION S

CREEN ONLY in the event of a fault and NOT in the ERROR LOG Menu.

Err E1.7

TIG DEFAULTS MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on VISION S

CREEN ONLY in the event of a fault and NOT in the ERROR LOG Menu.

(continued)

Loading...

Loading...