Page 58 FF6300 Operating Manual

Before starting the machine, always check the following:

• All energy supplies are OFF and the system reset button is released.

• Check that the machine is securely mounted to the work piece.

• Check that all the lines,

cables, and hoses are prop-

erly connected and secured

away from moving parts.

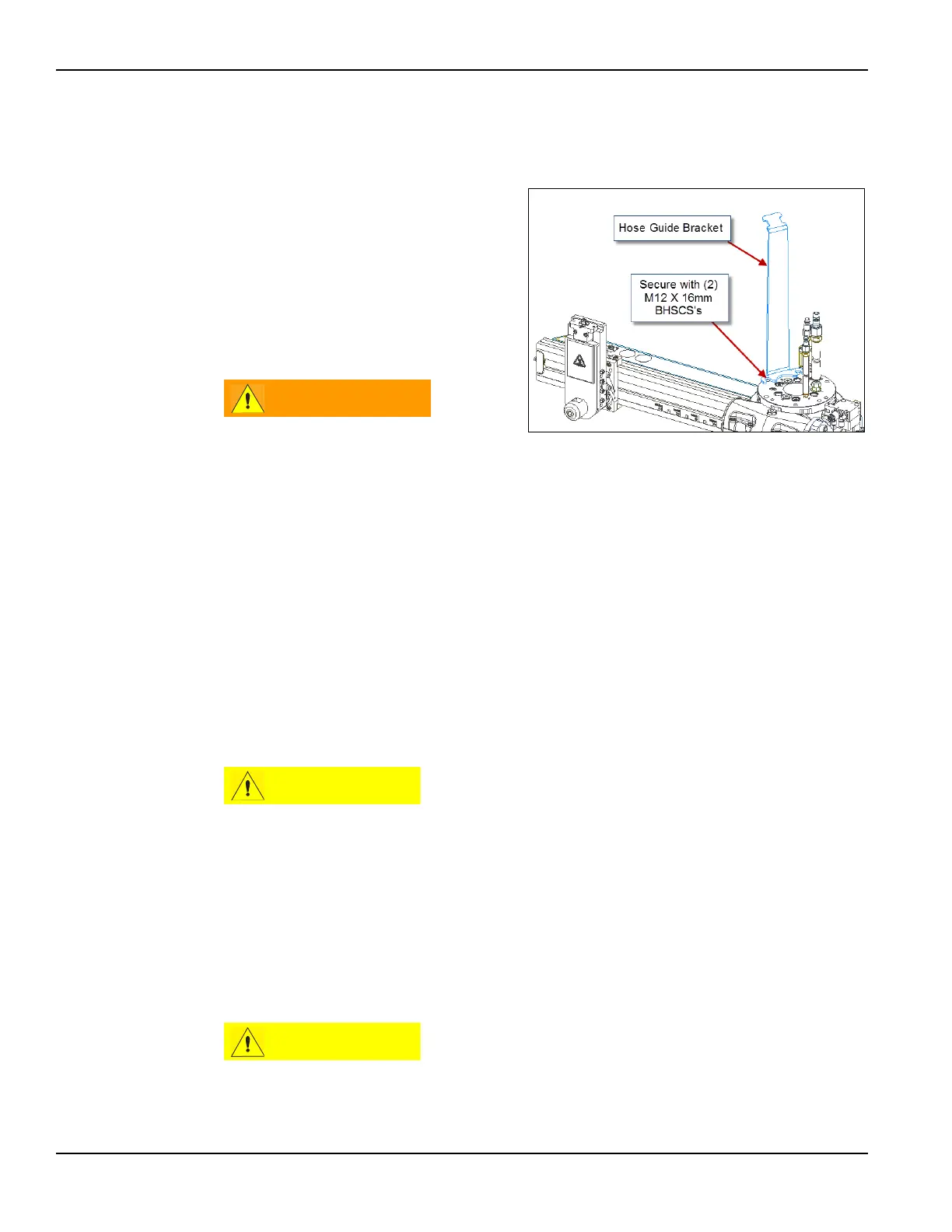

A lightweight bracket is

supplied in the tool kit for

securing the hoses as

shown in Figure 4-1.

Broken air or hydraulic lines

can whip around, striking the

operator or bystanders. Always

check that the supply lines to

the machine are secure and cannot be hit by moving parts.

• For hydraulically driven machines check that all hoses and fittings are leak

free. Hydraulic oil leaks could contaminate the environment or cause a

slipping hazard. Clean up any spills, and repair any leaks before operating

this machine.

• Check that all the machine parts are secure, including the tool head, tool

bit, chucks, and clamps.

• Check that the tool head is set at the desired angle and is tight.

• Check that the feed direction and rate are set correctly (Section 3.12 on

page 48).

Check that the turning arm is securely clamped to the main body and that it

will not hit any obstructions around the workpiece. Check that there is

clearance by manually rotating the machine one full revolution.

• Check that all handles and tools are removed from the machine.

• Check that all preventative maintenance is complete (Section 5) and the

drip rate is set correctly on the pneumatic conditioning unit (PCU). Refer to

Section 5.3.1 on page 64.

• Check that the emergency stop button is reset.

Metal chips and other debris can damage the machine and degrade its

performance. Ensure all metal chips and other debris are removed from the

machine before and after each use.

FIGURE 4-1. DETAIL OF HOSE GUIDE BRACKET

Loading...

Loading...