Position of the hook and needle

Service Instructions 967 - 02.0 - 12/2015

51

10 Position of the hook and needle

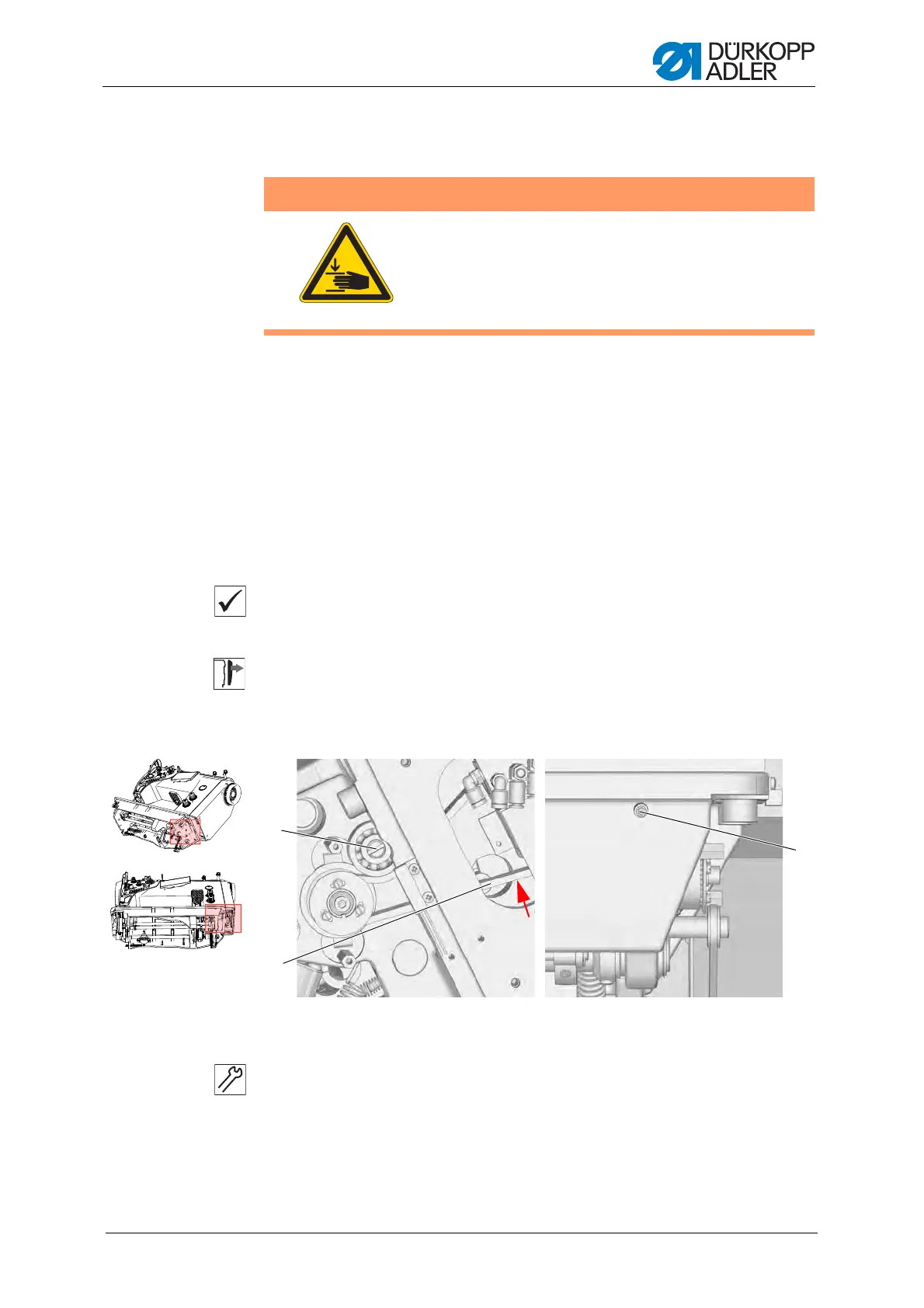

10.1 Tensioning the hook drive belt

A special measurement tool is required to achieve the necessary setting.

If you have to guess at the setting for the belt tension, bear the following

points in mind:

• If the tension is too high, the service life of the belt and ball bearings is

re

duced.

• If the tension is too low, the belt may slip off the pulleys.

Proper setting

When the toothed belt (2) is pressed in the direction of the arrow, about

midway betwee

n the pulleys, the belt should deflect about 3 mm.

Cover

•Belt cover (

p. 13).

• Tilt the machine head ( p. 10).

Fig. 34: Tensioning the hook drive belt

Setting steps

1. Loosen the adjusting screw (3).

2

. Turn the eccentric pin (1) with the tensioning pulley, and tension the

toothed belt (2).

3. Tighten the adjusting screw (3).

WARNING

Risk of injury!

Crushing injuries from moving parts.

Switch the machine off before checking and setting

th

e hook and the needle bar.

(1) - Eccentric pin

(2) - Toothed belt

(3) - Adjusting screw

①

②

③

Loading...

Loading...