Setting the drive

28

Service Instructions 967 - 02.0 - 12/2015

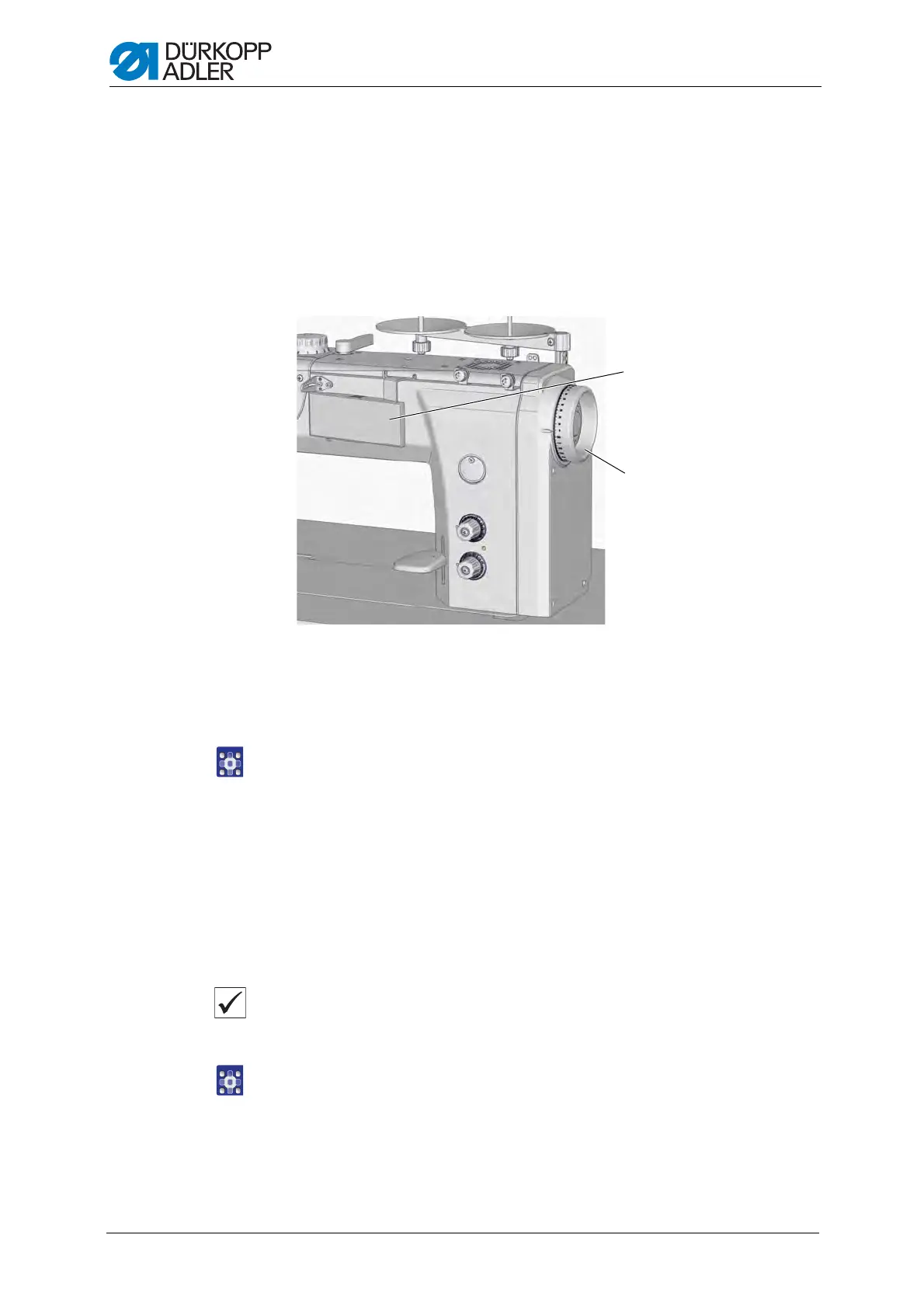

6.2 Adjusting the positioning of the machine

The machine will stop automatically at two angular positions on the main

shaft (of the handwheel). To ensure that the machine will properly stop at

these positions, you need to set the reference position of the handwheel.

The proper setting of the reference position requires that the drive ratio be-

tween motor and main shaft be input properly into the control program of

t

he machine.

Fig. 19: Adjusting the positioning of the machine

6.2.1 Determining the drive ratio in the control program

Setting steps

1. Select parameter setting mode on the OP1000 control panel (1) and set

th

e parameter t 08 19 ( DAC basic/classic Service Instructions).

2. Manually rotate the handwheel (2) by at least 2 turns.

The display on the control panel will show a new value for the drive

ratio.

3. Press the OK key to acknowledge this new parameter value.

6.2.2 Adjusting the reference position of the handwheel

Proper setting

The reference position is at 105° on the handwheel scale (2).

Setting steps

1. Select parameter setting mode on the OP1000 control panel (1) and set

the parameter t 08 10 ( DAC basic/classic Service Instructions).

(1) - OP1000 control panel (2) - Handwheel

①

②

Loading...

Loading...