STP-iS2207 Series Turbomolecular Pump

MT-89E-001-C

Page 147

MAINTENANCE AND INSPECTION

8

8.4 Maintenance

8.4.1 Recommended overhaul intervals

Regular overhaul (the cost of overhaul will be at your own charge) is required for safety and proper

use of STP pump.

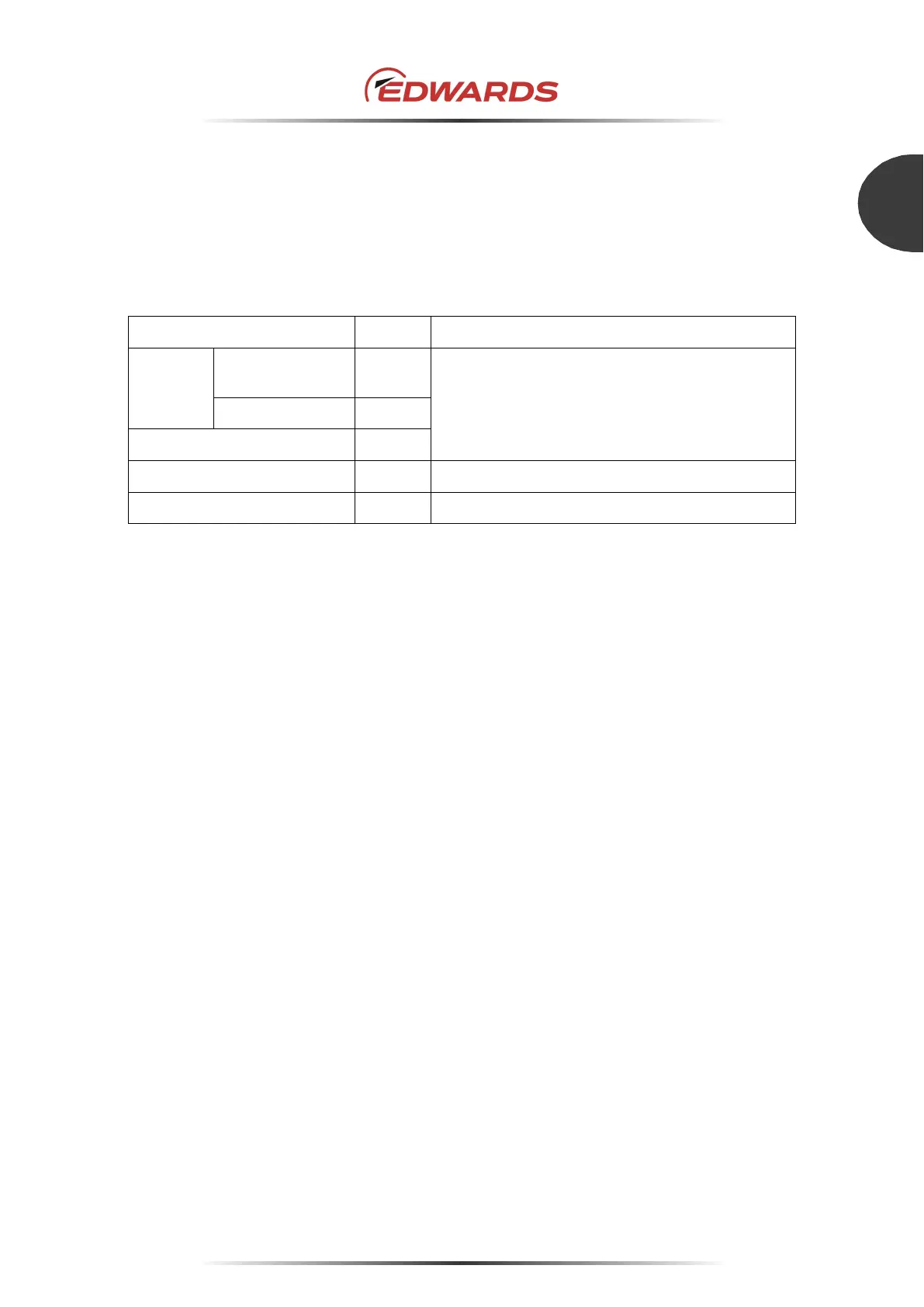

The recommended intervals for different process applications are tabulated below:

Process Intervals

Remarks

Etching

*1

Metal etch process

(deposition)

1 year Processes resulting in large amount of deposits in

the pump will require more frequent service

(includes non-etching process).

Other etch process

2 years

Other semiconductor process 2 years

Clean application 5 years

No gases used (only vacuum pumping)

Other use 2 years

Dependent on application, contact Edwards.

*1

"Etching" includes semiconductor etching and LCD etching.

Note: When "First Damage Limit" warning or "Second Damage Limit" warning is detected, it is

essential to have the touch down bearings replaced regardless of the recommended

overhaul intervals. Warning detection is indicated by flashing of "FAILURE" LED (3 flashes in

orange), a message on the display unit iDT-001 (optional accessory) or the STP-Link

(optional accessory).

8.4.2 Standard replacement parts

When overhauling pumps, upper and lower touch down bearing, O-rings will be replaced as standard

replacement parts.

Loading...

Loading...