Commissioning Proline Prowirl F 200 PROFIBUS PA

102 Endress+Hauser

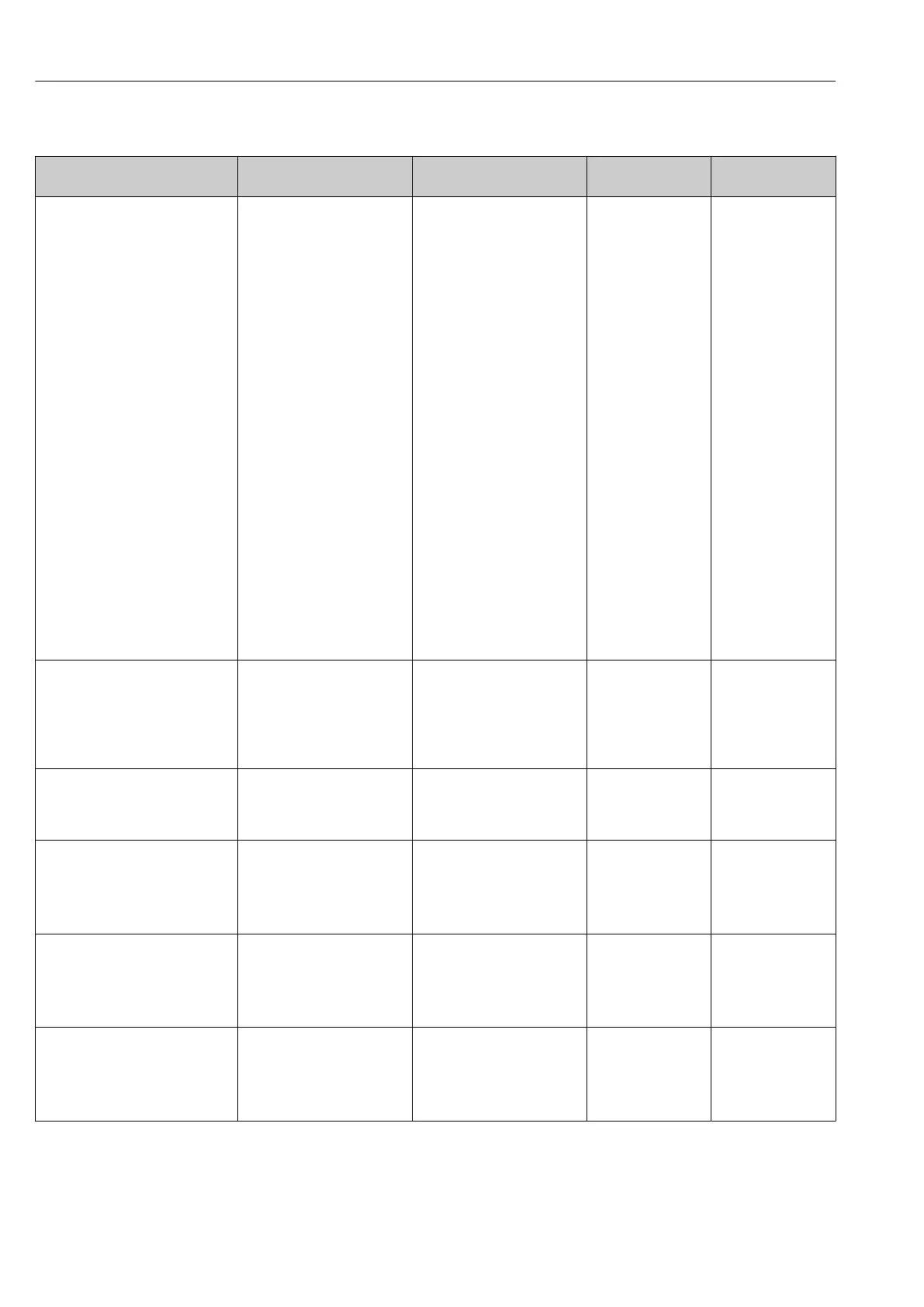

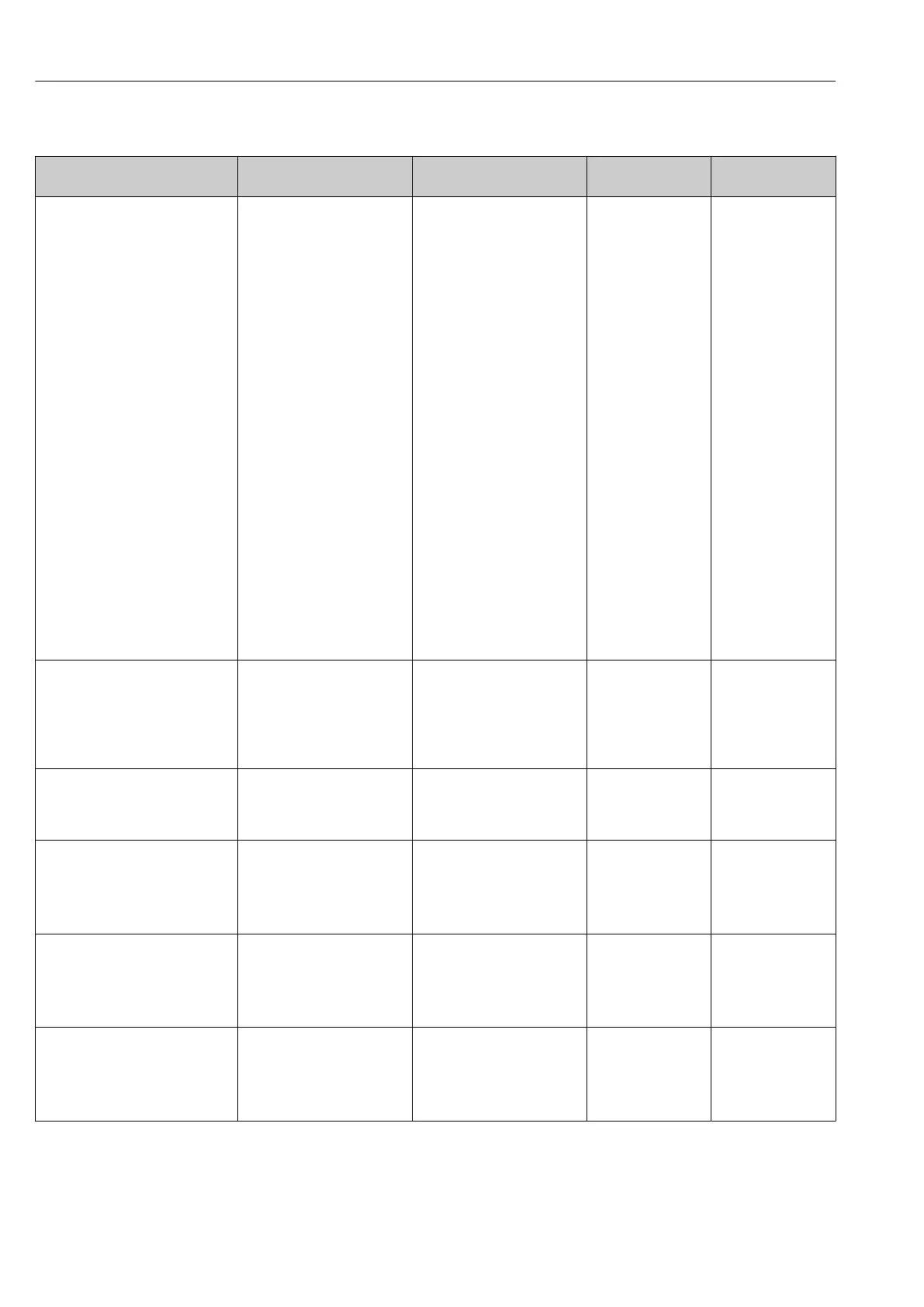

Parameter overview with brief description

Parameter Prerequisite Description Selection / User

entry

Factory setting

External value For the following order code:

"Sensor version", option "Mass

flow"

Assign variable from external

device to process variable.

Selection

NOTE!

If the pressure option is

selected, the pressure is read

in externally via a pressure

transmitter.

The pressure must be read in

with the Pascal unit so that

pressure compensation can be

read in correctly.

▸ Select the Pa option in the

Pressure unit parameter.

For detailed information

on the calculation of the

measured variables with

steam: → 186

For detailed information

on setting the parameter

in steam applications,

see the Special

Documentation for the

Wet Steam Detection

and Wet Steam

Measurement

→ 212 application

package.

• Off

• Pressure

• Relative pressure

• Density

• Temperature

• 2nd temperature

delta heat

Off

Atmospheric pressure In the External value

parameter, the Relative

pressure option is selected.

Enter atmospheric pressure

value to be used for pressure

correction.

Dependency

The unit is taken from the

Pressure unit parameter

0 to 250 bar 1.01325 bar

Delta heat calculation The Delta heat calculation

parameter is visible.

Calculates the transferred heat

of a heat exchanger (= delta

heat).

• Off

• Device on cold side

• Device on warm

side

Device on warm side

Fixed density For the following order code:

"Sensor version", option

"Volume flow"

Enter fixed value for medium

density.

Dependency

The unit is taken from the

Density unit parameter.

0.01 to 15 000 kg/m³ 1 000 kg/m³

Fixed temperature – Enter a fixed value for process

temperature.

Dependency

The unit is taken from the

Temperature unit parameter

–200 to 450 °C 20 °C

2nd temperature delta heat The 2nd temperature delta

heat parameter is visible.

Enter 2nd temperature value

to calculate the delta heat.

Dependency

The unit is taken from the

Temperature unit parameter

–200 to 450 °C 20 °C

Loading...

Loading...