System integration Proline Prowirl F 200 PROFIBUS PA

66 Endress+Hauser

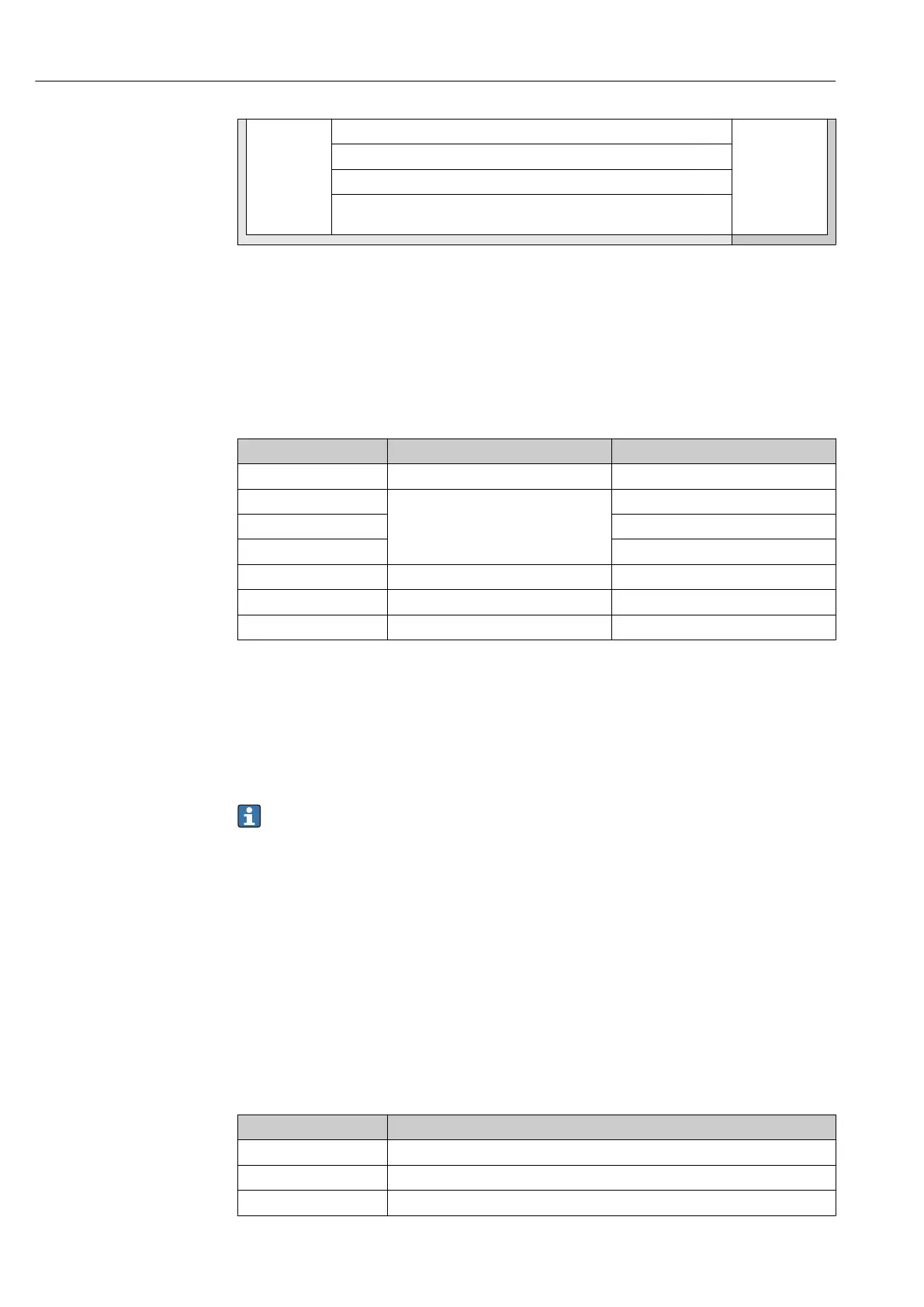

Configuration MODETOT ←

Analog Output block 1 → 69 Input values AO ←

Discrete Input block 1 to 2 → 70 Output values DI →

Discrete Output block 1 to

3

→ 70 Input values DO ←

Defined order of modules

The measuring device works as a modular PROFIBUS slave. In contrast to a compact slave,

a modular slave has a variable design and consists of several individual modules. The

device master file (GSD) contains a description of the individual modules (input and output

data) along with their individual properties.

The modules are permanently assigned to the slots, i.e. when configuring the modules, the

order and the arrangement of the modules must be respected.

Slot Module Function block

1…4 AI Analog Input block 1 to 4

5

TOTAL or

SETTOT_TOTAL or

SETOT_MODETOT_TOTAL

Totalizer block 1

6 Totalizer block 2

7 Totalizer block 3

8 AO Analog Output block 1

9…10 DI Discrete Input block 1 to 2

11…13 DO Discrete Output block 1 to 3

To optimize the data throughput rate of the PROFIBUS network, it is advisable to only

configure modules that are processed in the PROFIBUS master system. If this results in

gaps between the configured modules, these gaps must be assigned to the

EMPTY_MODULE.

9.3.2 Description of the modules

The data structure is described from the perspective of the PROFIBUS master:

• Input data: Are sent from the measuring device to the PROFIBUS master.

• Output data: Are sent from the PROFIBUS master to the measuring device.

AI module (Analog Input)

Transmit an input variable from the measuring device to the PROFIBUS master (Class 1).

The selected input variable, along with the status, is cyclically transmitted to the

PROFIBUS Master (Class 1) via the AI module. The input variable is depicted in the first

four bytes in the form of a floating point number as per the IEEE 754 standard. The fifth

byte contains standardized status information pertaining to the input variable.

Four Analog Input blocks are available (slot 1 to 4).

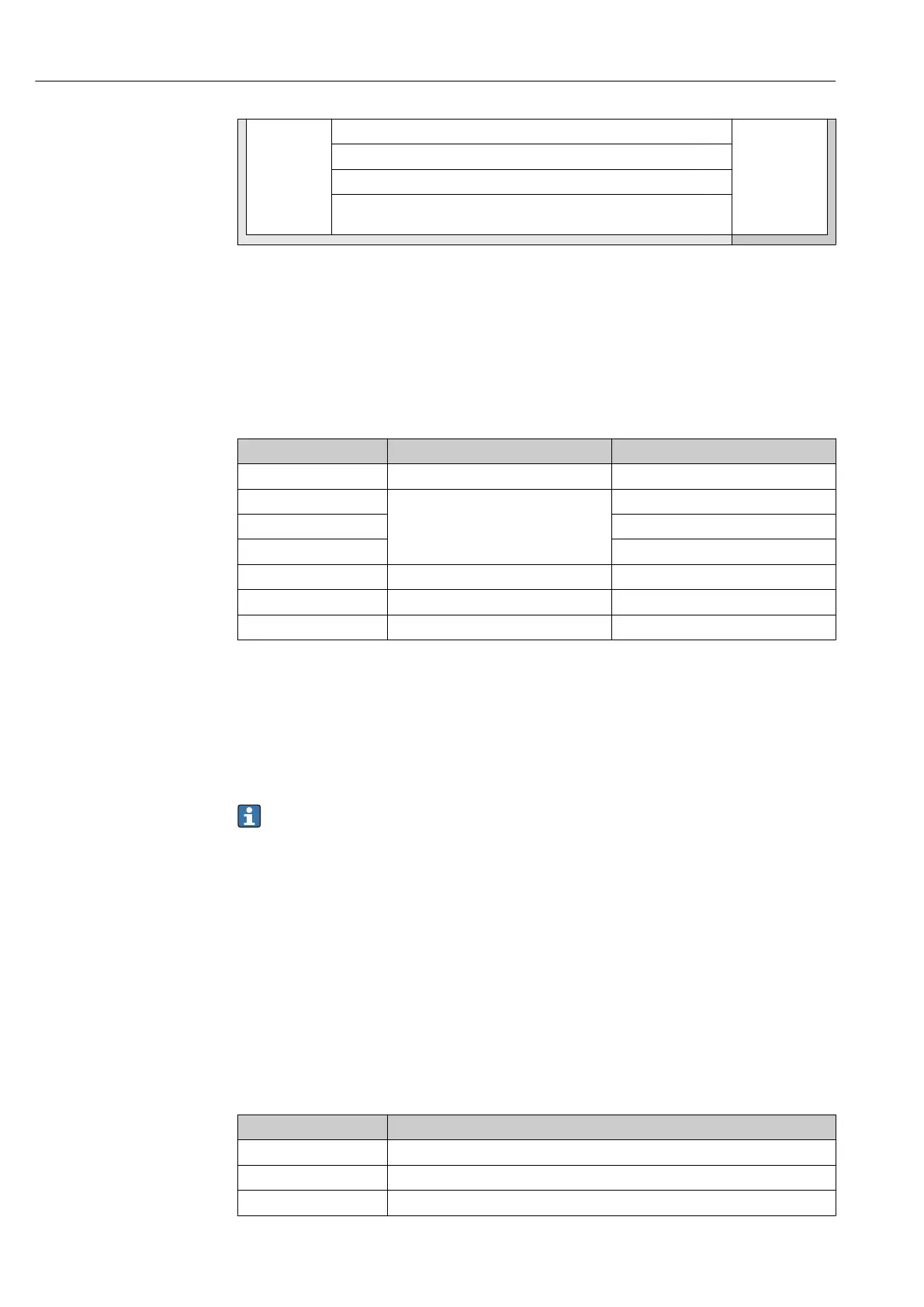

Selection: input variable

The input variable can be specified using the CHANNEL parameter.

CHANNEL Input variable

33122 Volume flow

32961 Mass flow

33093 Corrected volume flow

Loading...

Loading...