Proline Prowirl F 200 PROFIBUS PA System integration

Endress+Hauser 67

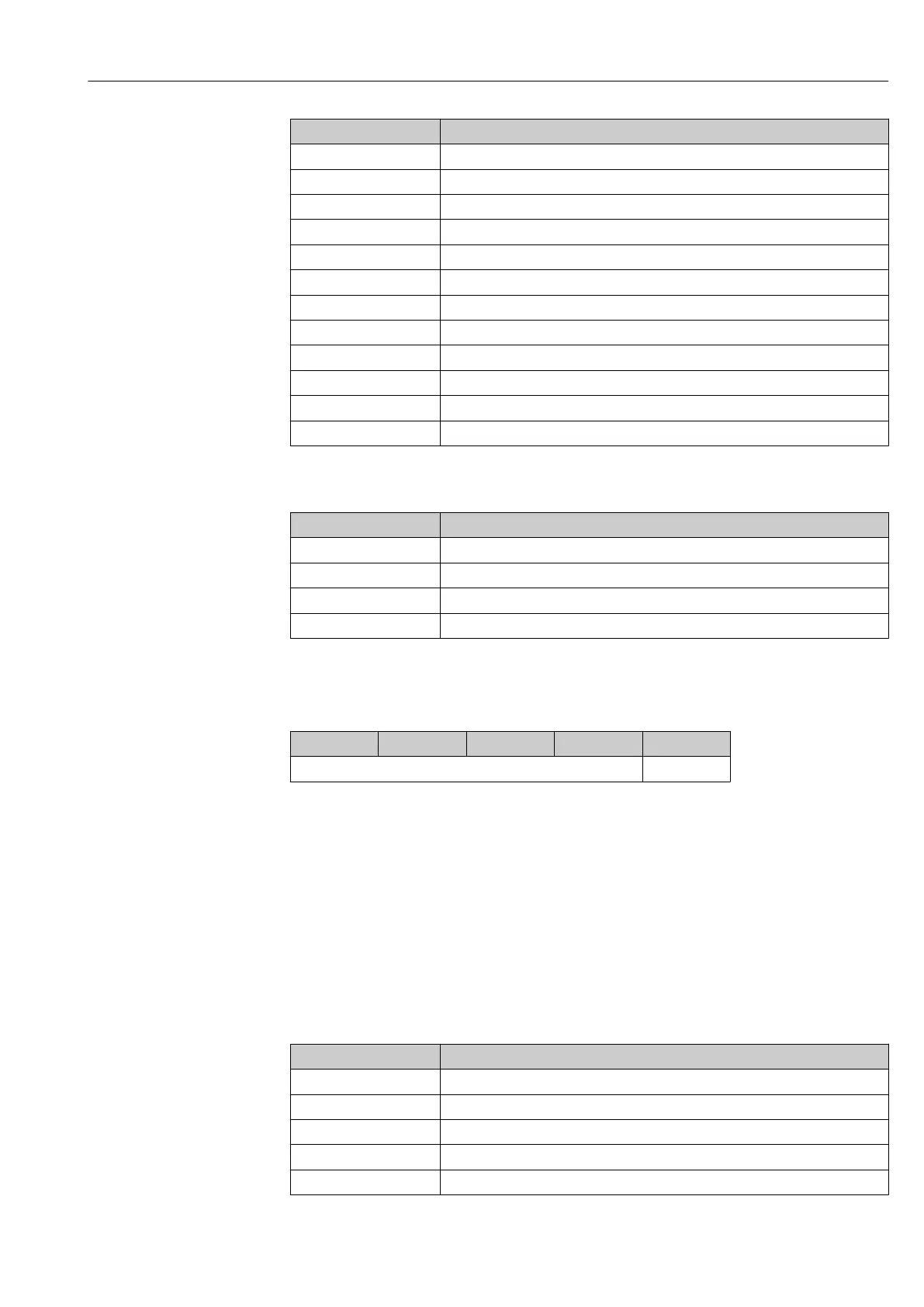

CHANNEL Input variable

708 Flow velocity

33101 Temperature

709 Calculated saturated steam pressure

710 Steam quality

466 Total mass flow

69 Energy flow

465 Heat flow difference

711 Reynolds number

32850 Density

1159 Pressure

2006 Specific volume

1305 Degree of overheating

Factory setting

Function block Factory setting

AI 1 Volume flow

AI 2 Mass flow

AI 3 Corrected volume flow

AI 4 Density

Data structure

Input data of Analog Input

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5

Measured value: floating point number (IEEE 754) Status

TOTAL module

Transmit a totalizer value from the measuring device to the PROFIBUS master (Class 1).

A selected totalizer value, along with the status, is cyclically transmitted to a PROFIBUS

Master (Class 1) via the TOTAL module. The totalizer value is depicted in the first four

bytes in the form of a floating point number as per the IEEE 754 standard. The fifth byte

contains standardized status information pertaining to the totalizer value.

Three Totalizer blocks are available (slot 5 to 7).

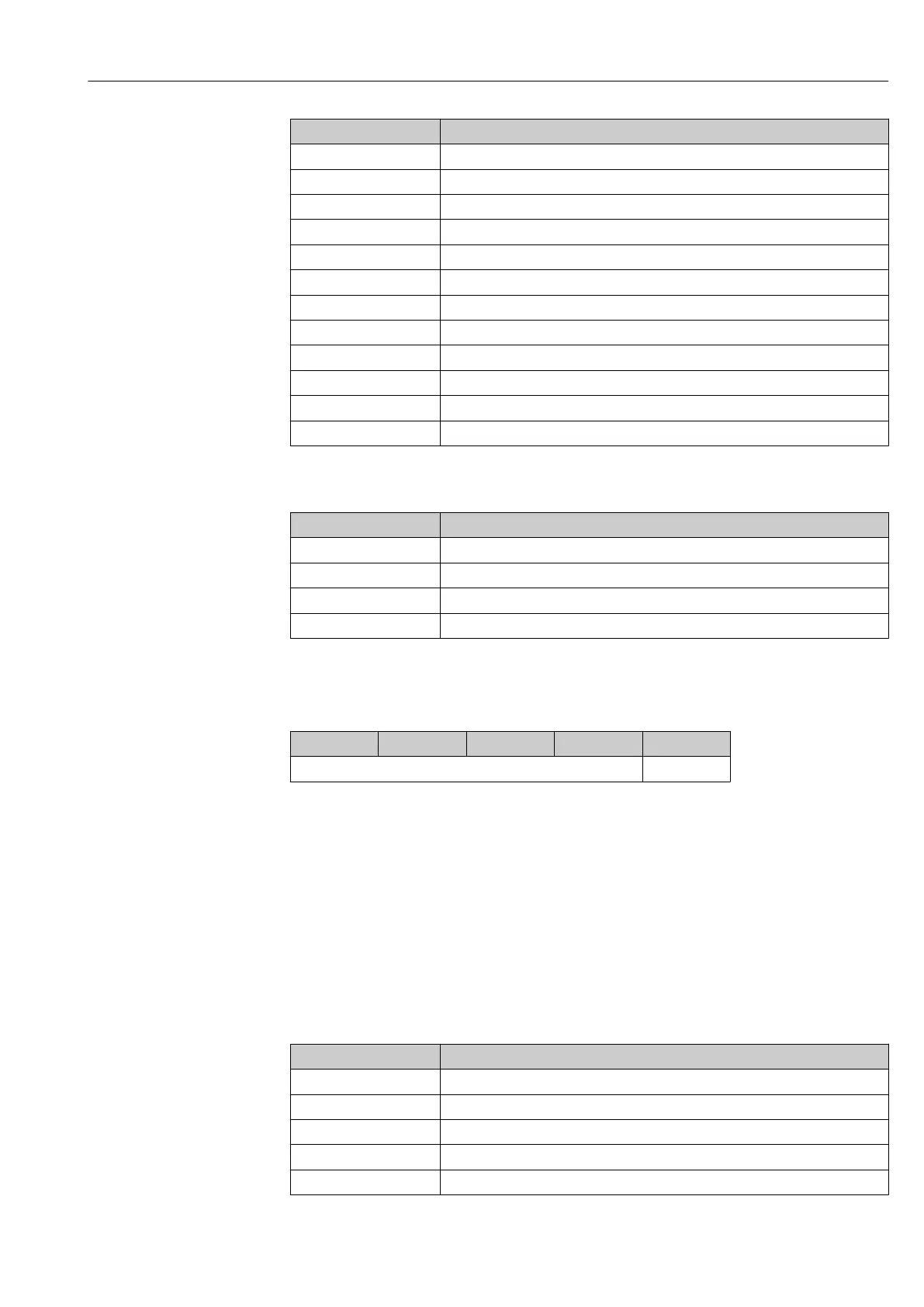

Selection: totalizer value

The totalizer value can be specified using the CHANNEL parameter.

CHANNEL Input variable

33122 Volume flow

32961 Mass flow

33093 Corrected volume flow

466 Total mass flow

467 Condensate mass flow

Loading...

Loading...