DSG-423 FUEL SYSTEM

04-24

The pinpoint tests below should be performed after the preliminary tests and “Engine Cranks but Will Not Start”

chart Steps 1-3. Any electrical diagnostics should have been performed to eliminate any sensor, GCP or solenoid

valve problems before proceeding.

Diagnostic Aids

Regulator Assembly (Converter & FCV): If no other problems have been identified, replace the fuel management

assembly with a known good part of the same pressure range. Retest.

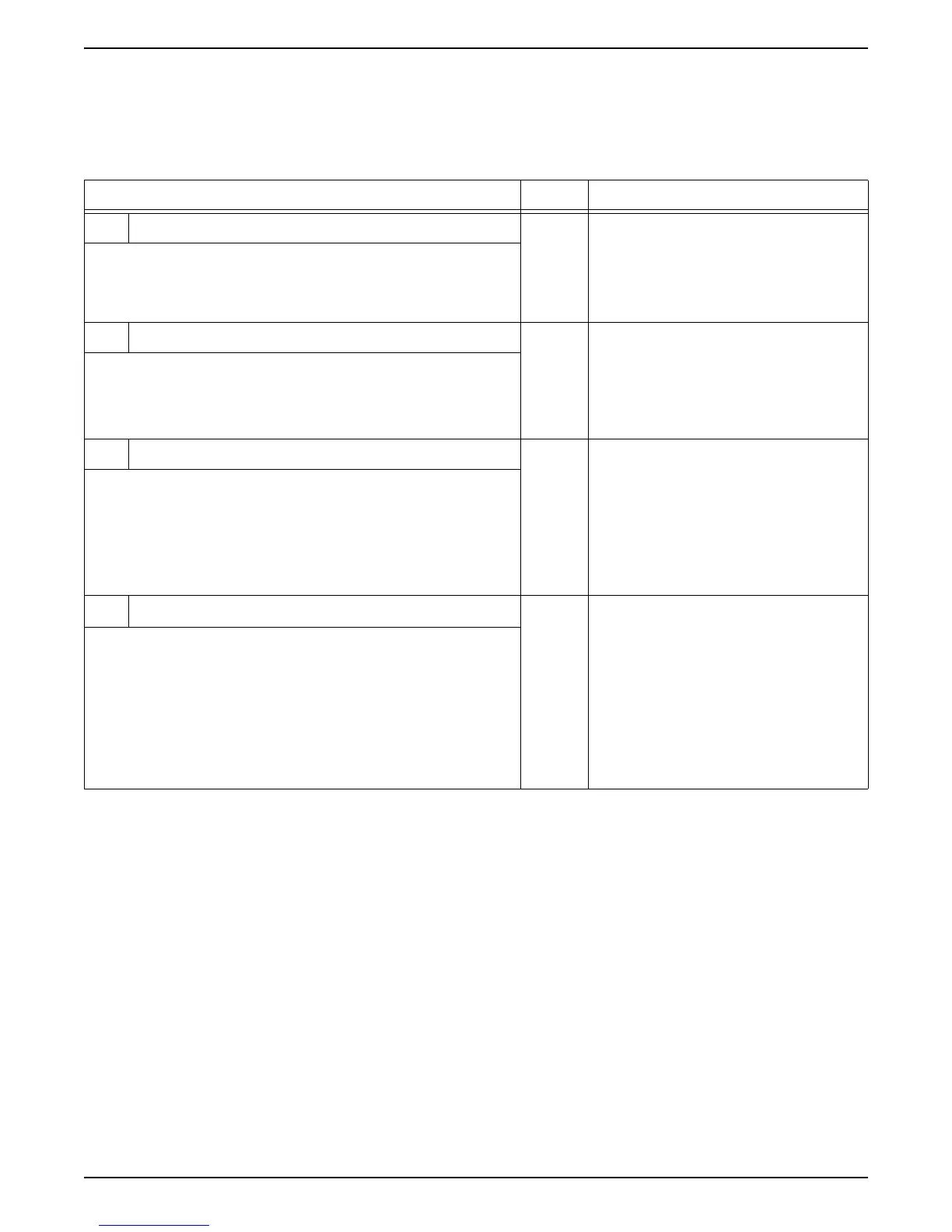

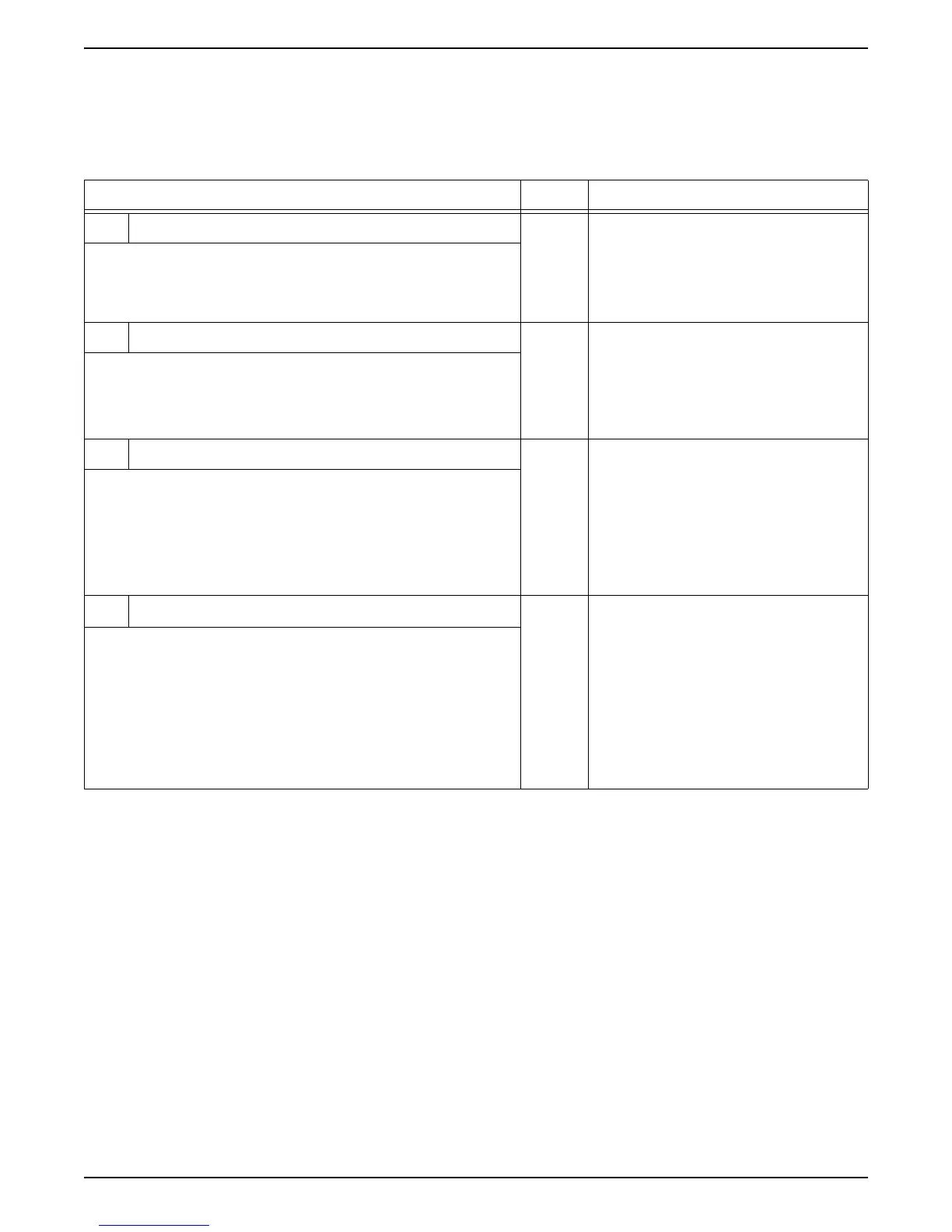

Emission Failure - Rich Mixture

Test Step Result Action to Take

1 Check for clogged or restricted air filter. Yes

No

This would indicate a clogged air

cleaner as the cause. Replace as

necessary.

Go to Step 2.

• Remove the air filter.

• Start the engine and re-check emission levels.

Has the (rich) emission failure been eliminated?

2 Check carburetor air valve for binding. Yes

No

Refer to section 475-1 for servicing the

carburetor.

Go to Step 3.

• With the air cleaner removed, pull the air valve piston

upwards to ensure free movement of the carburetor air

valve.

Is the air valve binding?

3 Check air valve operation. Yes

No

Refer to section 475-1 for servicing the

carburetor.

Go to Step 4.

• Using the WTK-1 test kit, connect the vacuum gauge

between the carburetor and the FCV valve to measure the

carburetor air valve vacuum (AVV).

• With the engine at idle and accelerating observe the

amount of measured vacuum.

Is the measured vacuum outside the specifications?

4 Check regulator operation. Yes

No

The Regulator is functioning properly

and the problem is with the FCV valve

or vacuum hoses. Inspect the vacuum

hoses and fittings, replace as

necessary. Replace the FCV valve

and retest.

The Regulator is malfunctioning. See

section 475R-1 for service of the

regulator.

• Using a secondary pressure gauge described in section

475G-1. (note: the secondary spring color and pressure

range)

• Start the engine.

Is the pressure constant and at -1.5 inches of w.c. as

specified?

Loading...

Loading...