DSG-423 ENGINE CONTROLS

08-9

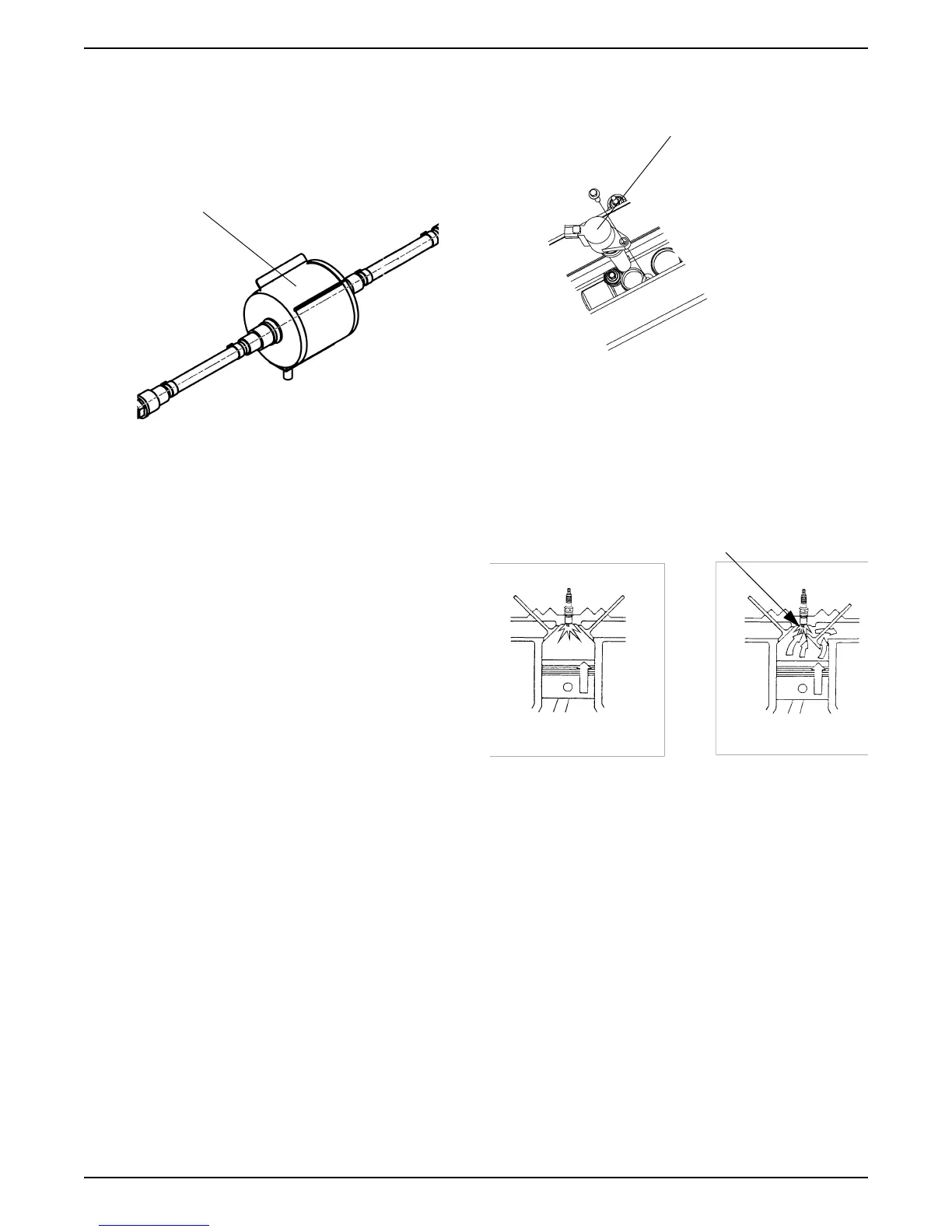

Fuel Filter

The fuel filter is an inline filter assembly. Refer to

Section 4 for information on relieving fuel pressure,

disconnecting fuel lines and fuel filter replacement.

Fuel Pump Electrical Circuit

When the key is first turned “ON”, the GCP energizes

the fuel pump relay for two seconds to build up the fuel

pressure quickly. If the engine is not started within two

seconds, the GCP shuts the fuel pump off and waits

until the engine is cranked. When the engine is cranked

and crankshaft position signal has been detected by the

GCP, the GCP supplies 12 volts to the fuel pump relay

to energize the electric fuel pump.

An inoperative fuel pump will cause a “no-start”

condition. A fuel pump which does not provide enough

pressure will result in poor performance.

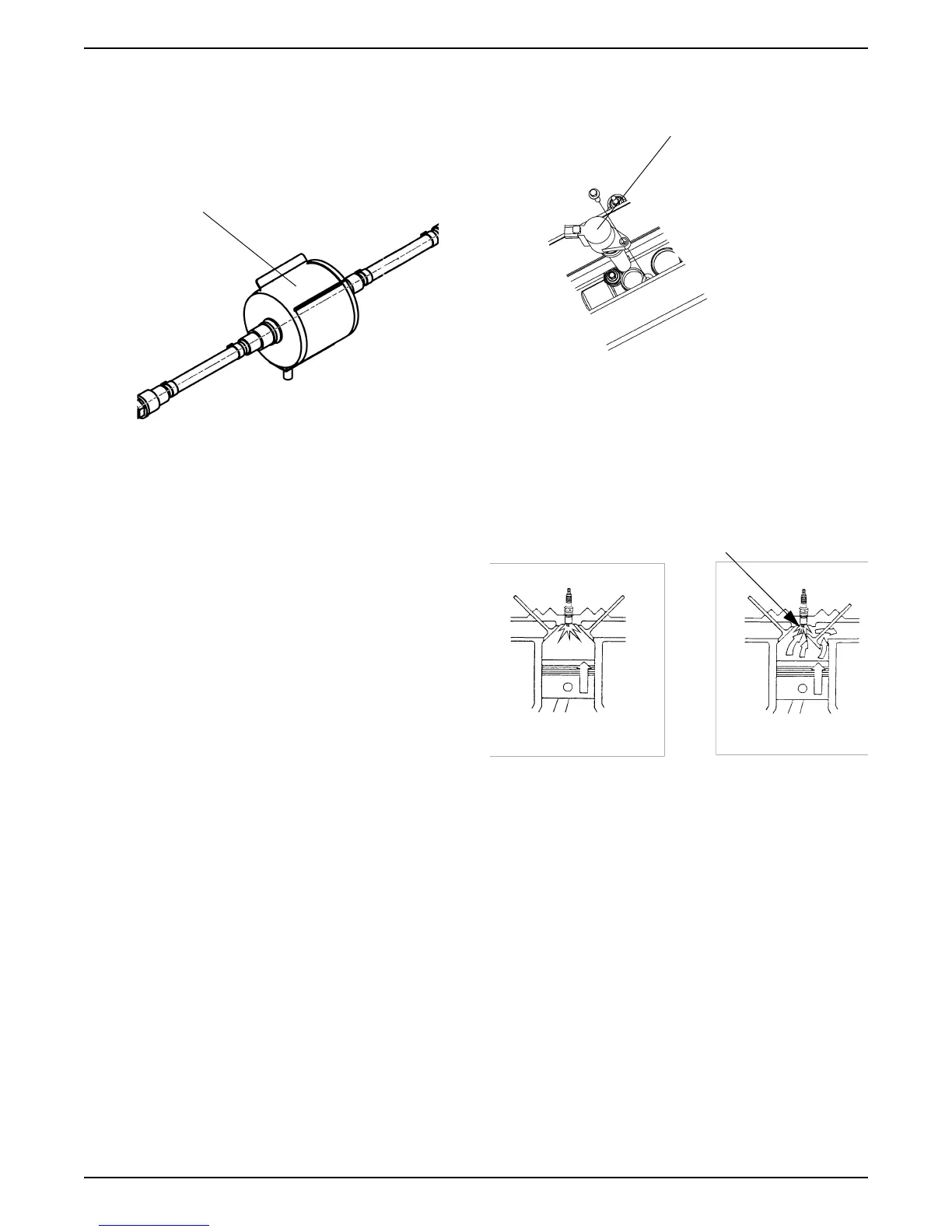

Coil-on-plug Ignition

The coil-on-plug ignition system controls fuel

combustion by providing a spark to ignite the

compressed air/fuel mixture at the correct time. To

provide optimum engine performance, fuel economy,

and control of exhaust emissions, the GCP controls the

spark advance of the ignition system. Coil-on-plug

ignition has the following advantages over a mechanical

distributor system:

• No moving parts

• Less maintenance

• Remote mounting capability

• No mechanical load on the engine

• More coil cooldown time between firing events

• Elimination of mechanical timing adjustments

• Increased available ignition coil saturation time

• Elimination of high tension wires

The coil-on-plug design has individual coils mounted

directly over each spark plug. Each cylinder is paired

with its opposing cylinder in the firing order, so that one

cylinder on compression fires simultaneously with the

opposing cylinder on exhaust. The spark that occurs in

the cylinder on the exhaust stroke is referred to as a

“waste spark”.

The primary coils in the coil pack are triggered by the

“ignition coil feed#1” and ignition coil feed #2” signals

from the GCP.

Ignition Coil

(coil-on-plug)

Power Stroke Exhaust Stroke

(waste spark)

Loading...

Loading...