DSG-423 ENGINE

02-18

Valve Tappet - Replacement

CAUTION: During engine repair procedures,

cleanliness is extremely important. Any foreign

material, including any material created while

cleaning gasket surfaces, that enters the oil

passages, coolant passages or the oil pan can

cause engine failure.

NOTE: Valve tappets are select fit and the valve

clearance must be checked before removing the

tappets -- Refer to“Valve Clearance Check” on page 45

of this section.

1. Remove camshafts -- Refer to“Camshafts -

Removal” on page 18 of this section.

CAUTION: If the camshafts and valve tappets are to

be reused, mark the location of the valve tappets to

make sure they are assembled in their original

positions.

NOTE: The number on the valve tappets only reflects

the digits that follow the decimal. For example, a tappet

with the number 0.650 has the thickness of 3.650 mm.

2. Remove and inspect valve tappets.

3. Reverse procedure to install.

NOTE: Coat valve tappets with clean engine oil prior to

installation.

Camshafts - Removal

CAUTION: The crankshaft, the crankshaft sprocket

and the pulley are fitted together by friction, with

diamond washers between the flange faces on each

part. For that reason, the crankshaft sprocket is

also unfastened if you loosen the pulley. Therefore,

the engine must be retimed each time the damper is

removed. Otherwise severe damage can occur.

1. Remove and/or disconnect components to allow

access and removal of the timing drive components.

Label if necessary to allow for correct reinstallation.

2. Remove timing chain and sprockets -- Refer

to“Timing Drive Components - Removal” on page 14

of this section.

CAUTION: Failure to follow the camshaft loosening

procedure can result in damage to the camshafts.

NOTE: Note the position of the lobes on the No. 1

cylinder before removing the camshafts for assembly

reference.

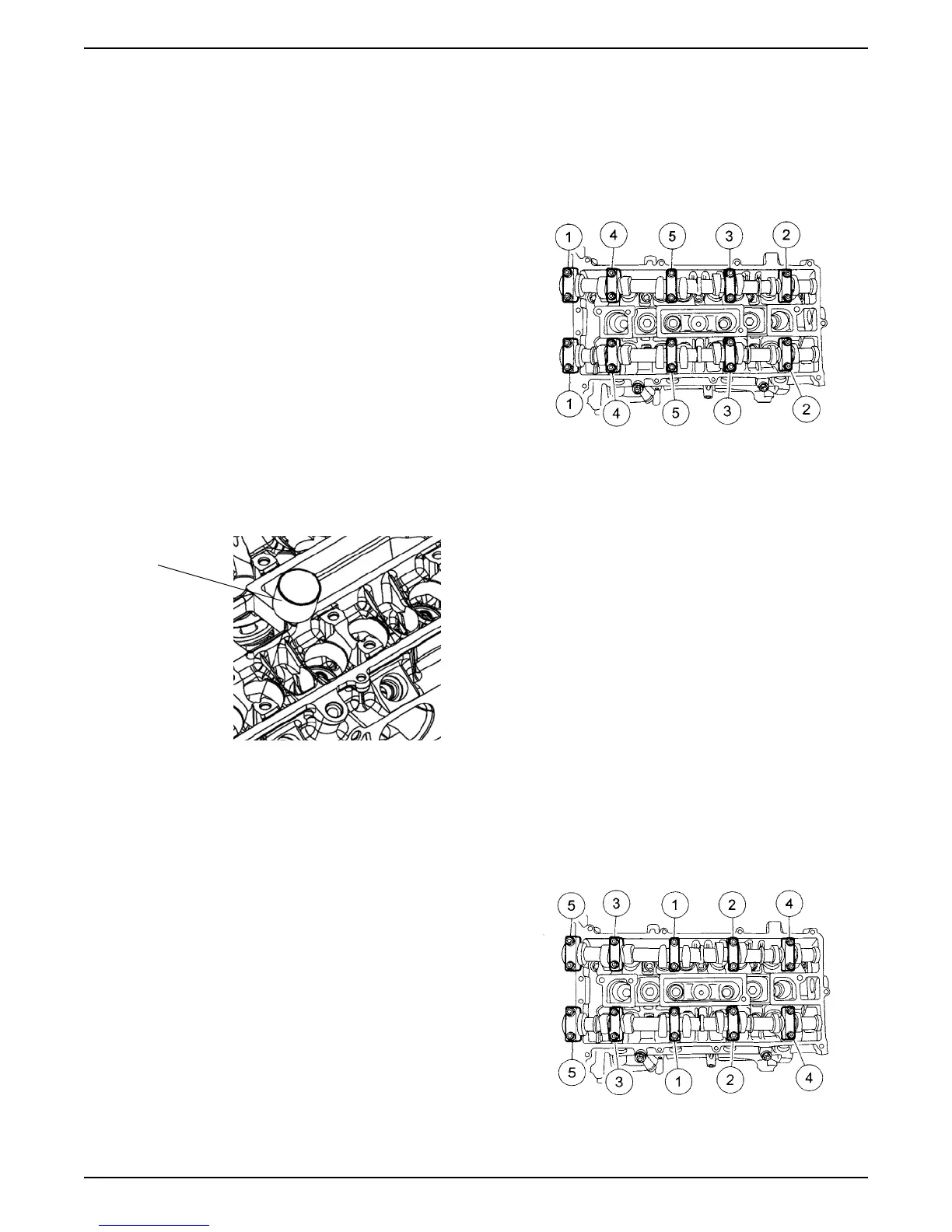

3. Loosen the camshaft bearing cap bolts, in sequence

shown, one turn at a time.

4. Repeat until all tension is released from the

camshaft bearing caps.

5. Remove bearing caps and camshafts.

Camshafts - Installation

CAUTION: Install the camshafts with the alignment

slots in the camshafts lined up so the camshaft

alignment plate can be installed without rotating the

camshafts. Make sure the lobes on the No. 1

cylinder are in the same position as noted in the

removal procedure. Rotating the camshafts when

the timing chain is removed, or installing the

camshafts 180 degrees out of position, can cause

severe damage to the valves and pistons.

NOTE: Lubricate the camshaft journals and bearing

caps with clean engine oil prior to installation.

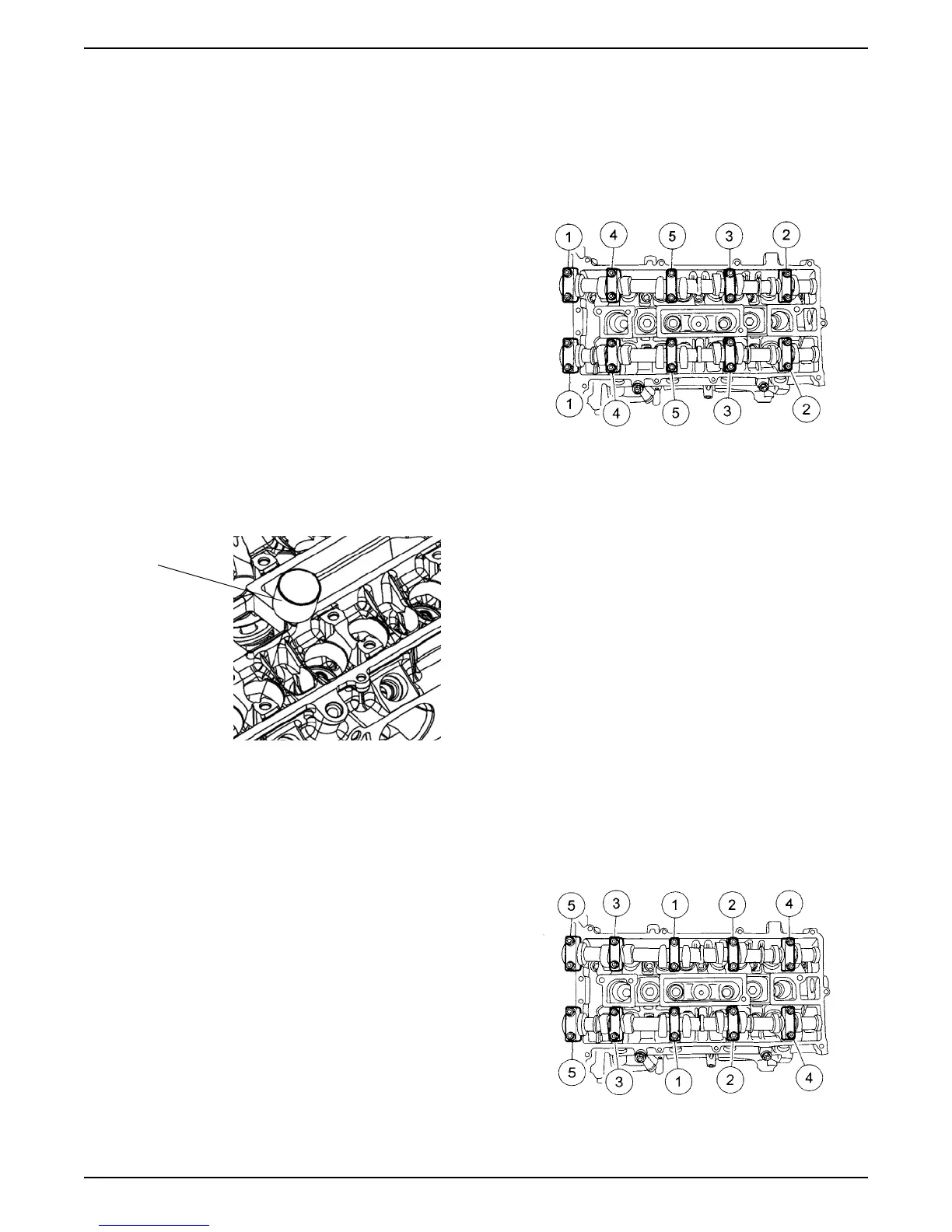

1. Install the camshafts and bearing caps. Tighten bolts

in the sequence shown in 3 stages:

• Stage 1: Tighten one turn at a time until tight

• Stage 2: Tighten bolts to 7 Nm (62 lb-in)

• Stage 3: Tighten bolts to 16 Nm (12 lb-ft).

Valve

Tappet

Loading...

Loading...