DSG-423 GENERAL INFORMATION

01-28

Piston Ring-to-Groove Clearance

1. Inspect for a stop in the grooves.

2. Measure the piston-to-groove clearance.

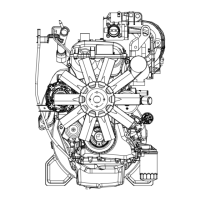

Crankshaft Connecting Rod Journal

Diameter

• Measure the crankshaft connecting rod journal

diameters in at least two directions perpendicular to

one another. The difference between the

measurements is the out-of-round. Verify the journal

is within the wear limit specification.

Crankshaft Connecting Rod Journal Taper

• Measure the crankshaft rod journal diameters in two

directions perpendicular to one another at each end

of the connecting rod journal. The difference in the

measurements from one end to the other is the

taper. Verify measurement is within the wear limit.

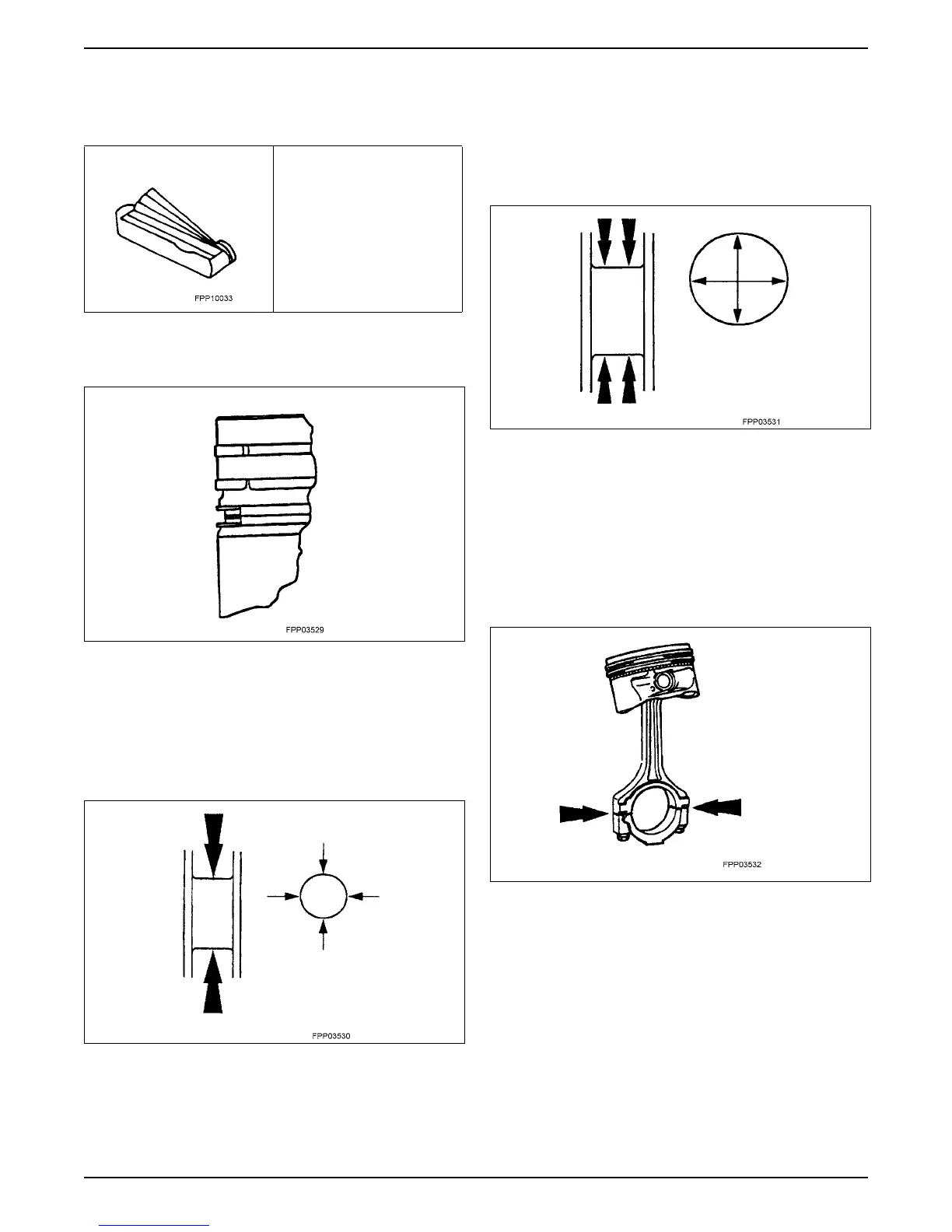

Connecting Rod Cleaning

CAUTION: Do not use a caustic cleaning solution or

damage to connecting rods can occur.

NOTE: The connecting rod large end is mechanically

split or cracked to produce a unique parting face. This

produces a locking joint. Parts are not interchangeable.

• Mark and separate the parts and clean with solvent.

Clean the oil passages.

Special Tool(s)

Feeler Gauge

D81L-4201-A or Equivalent

Special Service Tools called for

by the procedures can be

obtained by calling:

1-800-ROTUNDA

(1-800-768-8632)

Loading...

Loading...