DSG-423 FUEL SYSTEM

04-30

DIAGNOSIS AND TESTING - GASOLINE

NOTE: For diagnosis of Electronic Engine Control -

refer to Section 08.

Visual Inspection

Check for dirt or water in the fuel tank. Water and dirt

that accumulate in the fuel tank can cause a restricted

fuel line, filter or a malfunction of the fuel pump.

Condensation, which is the greatest source of water

entering the fuel tank, is formed by moisture in the air

when it strikes the cold interior walls of the fuel tank.

Check the fuel filter. If the accumulation of dirt and water

in the filter is excessive, the fuel tank should be

removed and flushed, and the line from the fuel pump to

the tank should be blown out.

Check fuel lines for damage. Air leakage in the fuel inlet

line can cause low fuel pump pressure and volume.

Check fuel tank vent. A restricted fuel tank vent can

cause low fuel pump pressure and volume and can

result in collapsed inlet hoses or a collapsed fuel tank.

High or low pressure are the two most likely fuel pump

troubles that will affect engine performance. Low

pressure will cause a lean mixture and fuel starvation at

high speeds, and excessive pressure will cause high

fuel consumption and possible flooding.

Fuel Pressure Check

WARNING: REFER TO WARNINGS AT THE

BEGINNING OF THIS SECTION.

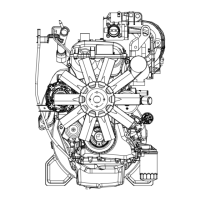

1. Remove the Schrader valve cap and attach a fuel

pressure gauge.

2. Bleed air from guage line into a suitable container.

3. Fuel pressure should be as follows:

• Key on, Engine off: 414-448 kPa (60-65 psi)

• Engine running: 414-448 kPa (60-65 psi)

If fuel pressure is insufficient, check for a clogged pump

filter, screen or fuel filter. Also check for a break or

restriction in the fuel lines. If fuel pump is inoperative,

check for damaged or loose ground or improper wiring.

Make sure fuel lines connections area tight and not

leaking.

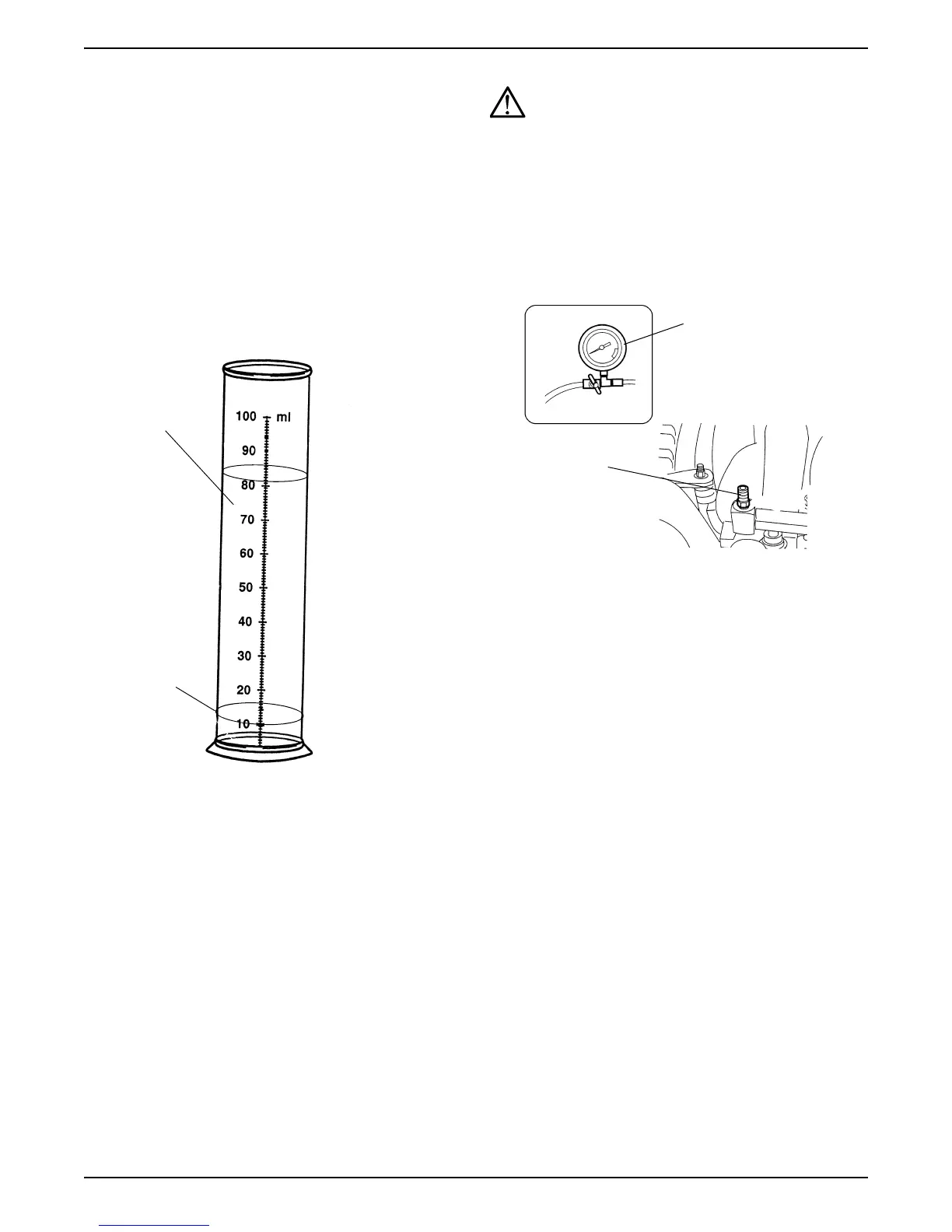

Fuel

Sample

Water Falls

to Bottom

Fuel Pressure

Gauge 310-012

Schrader

Valve

Loading...

Loading...