DSG-423 ENGINE

02-45

64.Install oil level indicator tube:

• Tighten to 10 Nm (89 lb-in).

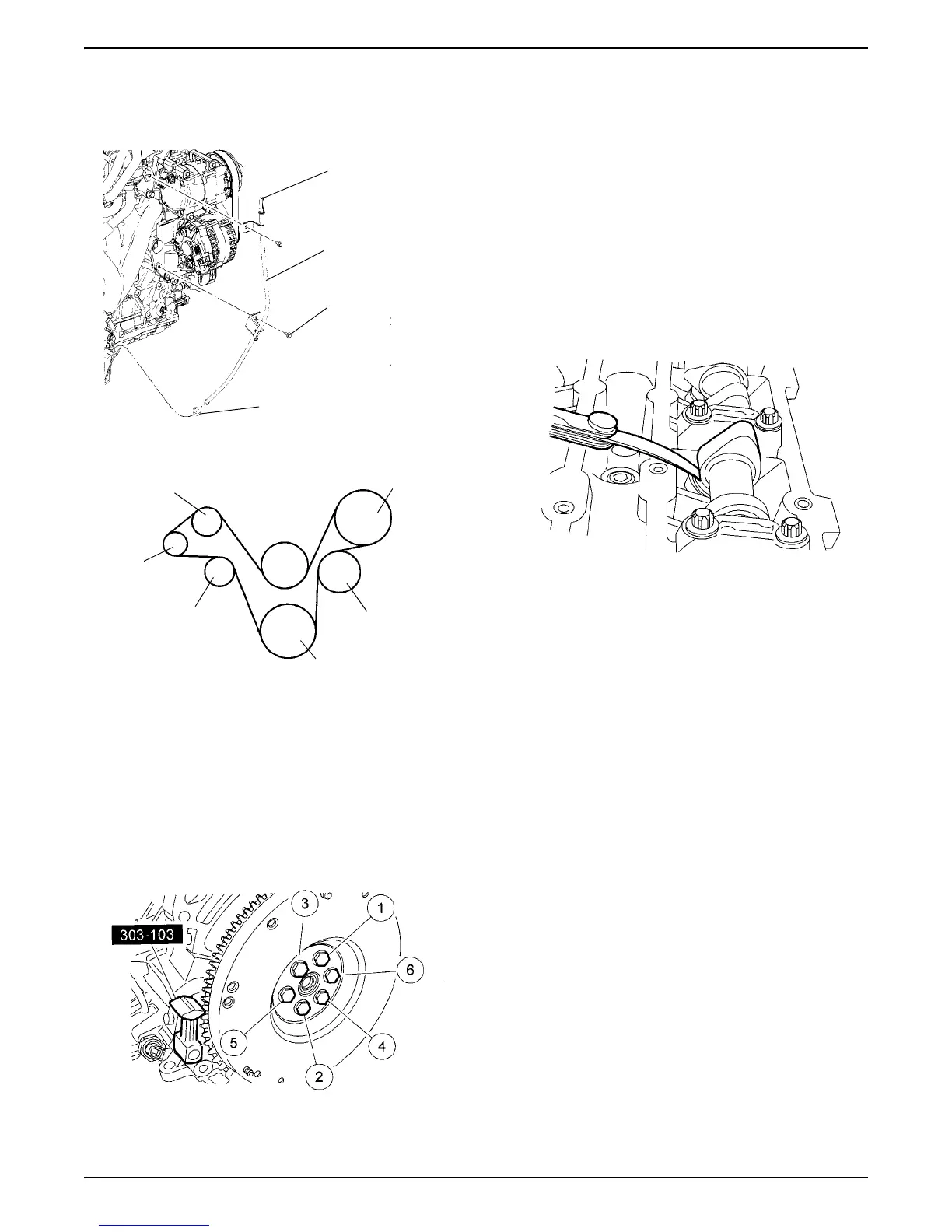

65.Install accessory drive belt.

66.Install any tubes, hoses or components removed or

disconnected.

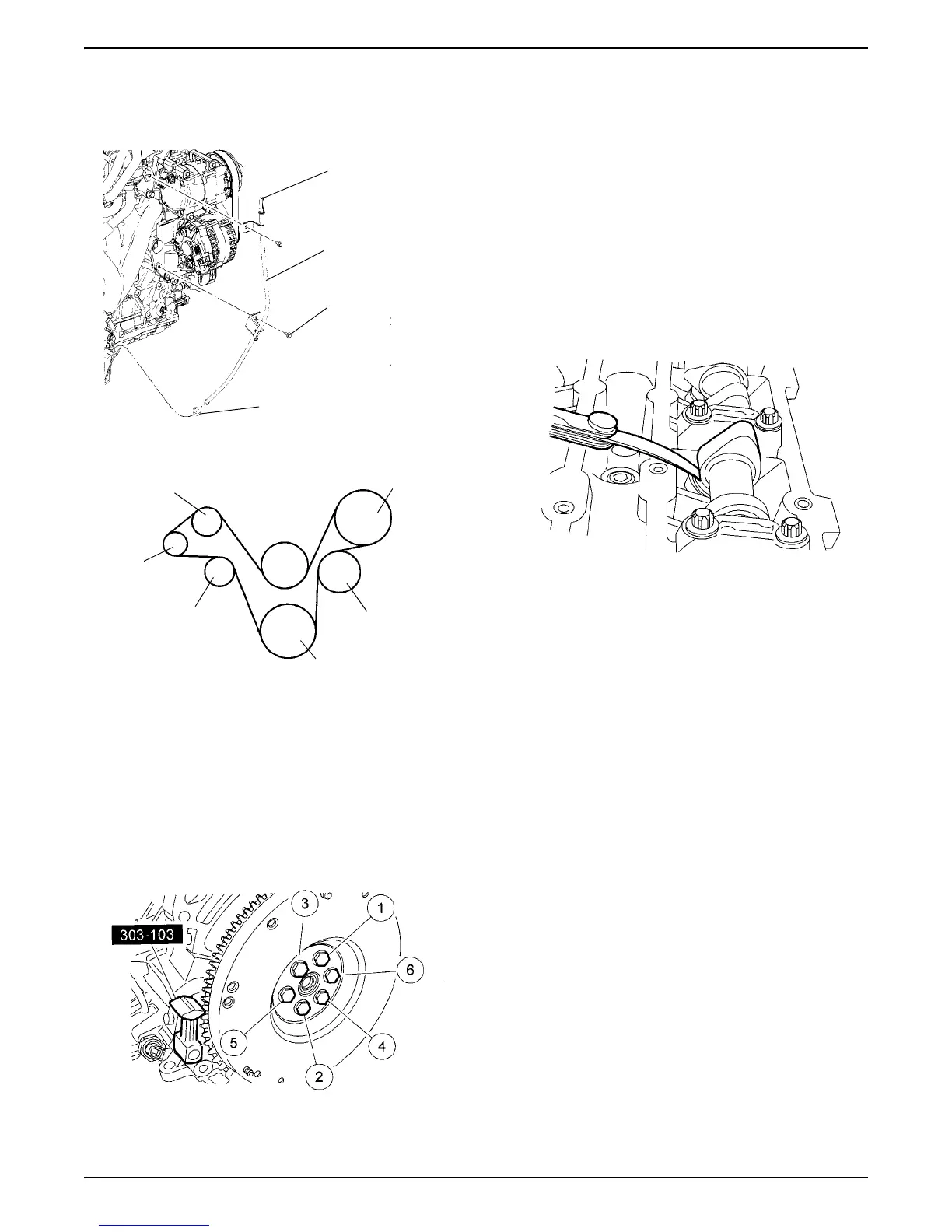

67.Remove engine from engine stand and install

flywheel or flexplate.

68.Using special tool, tighten bolts in the sequence

shown in 3 stages:

• Stage 1: Tighten to 50 Nm (37 lb-ft)

• Stage 2: Tighten to 80 Nm (59 lb-ft)

• Stage 3: Tighten to 112 Nm (83 lb-ft).

69.Lubricate transmission input shaft pilot bearing with

grease.

ADJUSTMENTS

Valve Clearance Check

1. Remove camshaft cover -- Refer to“Camshaft Cover

- Removal” on page 6 of this section.

CAUTION: Turn the engine clockwise only, and use

the crankshaft bolt only.

2. Use a feeler gauge to measure each valve’s

clearance and record its location. A mid range

clearance is most desirable:

• Intake: 0.22-0.28 mm (0.008-0.011 inch)

• Exhaust: 0.27-0.33 mm (0.010-0.013 inch)

NOTE: Measure each valve’s clearance at base circle

with lobe pointed away from the tappet, before

removing camshafts. Failure to measure all clearances

prior to removing camshafts will necessitate repeated

removal and installation and wasted labor time.

3. Select tappets and mark location using the following

formula:

• tappet thickness = measured clearance, plus

base tappet thickness, minus most desirable

thickness.

NOTE: If any tappets do not measure within

specifications, install new tappets in those locations --

Refer to“Valve Tappet - Replacement” on page 18 of

this section.

Oil Level

Indicator

Tube

Bolt

O-ring

Power Steering

Crankshaft

Coolant Pump

Fan

Tensioner

Idler

Generator

Loading...

Loading...