DSG-423 ENGINE

02-37

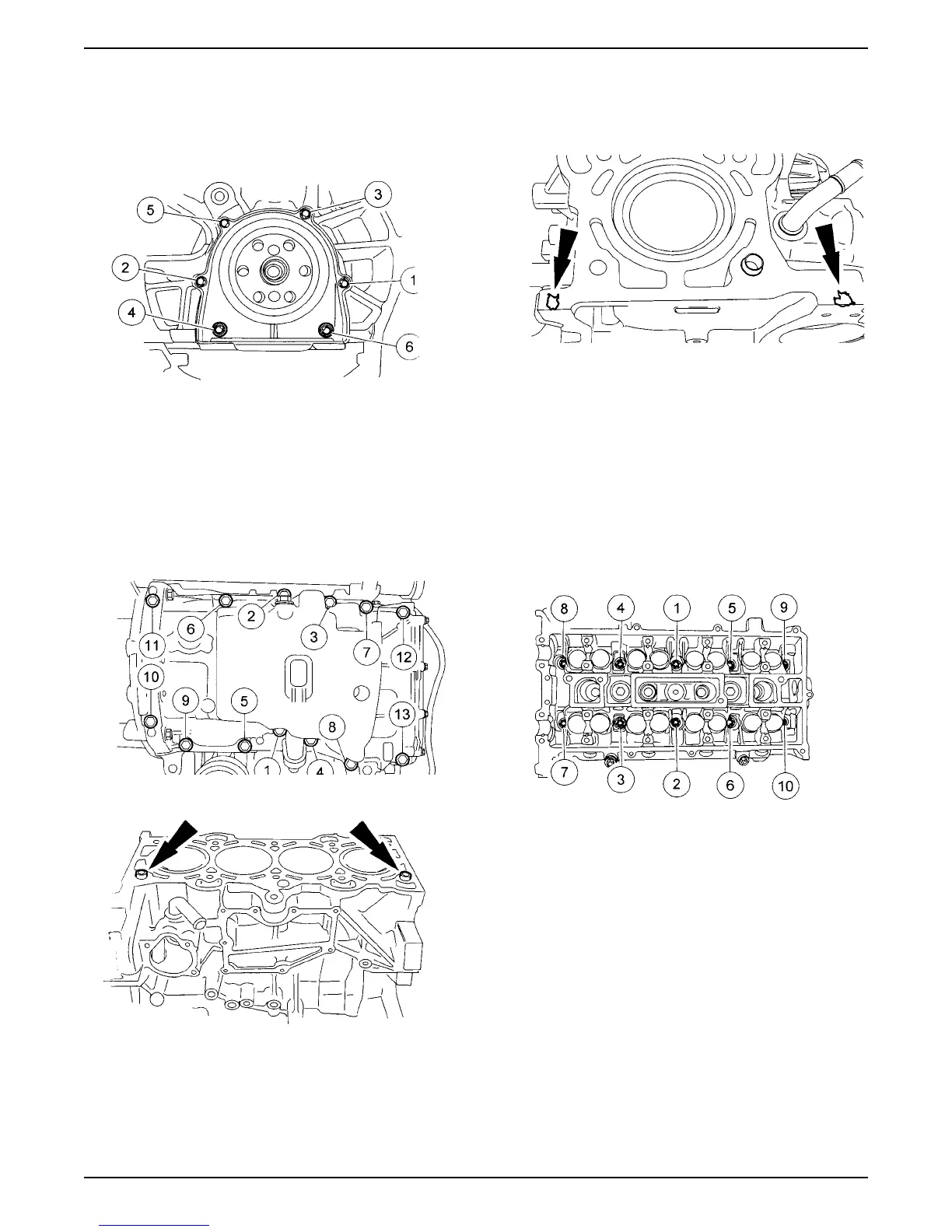

6. Using special tool 303-328, install a new crankshaft

rear seal and retainer plate assembly. Tighten bolts

in the sequence shown:

• Tighten to 10 Nm (89 lb-in).

NOTE: If oil pan is not secured within 4 minutes, the

sealant must be removed and the sealing area

recleaned -- Refer to“Engine Cleaning” on page 34 of

this section.

7. Apply a 2.5 mm (0.1 in) bead of silicone gasket and

sealant to the oil pan. Install the oil pan and bolts.

Tighten in the sequence shown:

• Tighten to 25 Nm (18 lb-ft).

8. Install cylinder head alignment dowels until fully

seated in block.

NOTE: If cylinder head is not secured within 4 minutes,

the sealant must be removed and the sealing area

recleaned -- Refer to“Engine Cleaning” on page 34 of

this section.

9. Apply silicone gasket and sealant to the locations

shown.

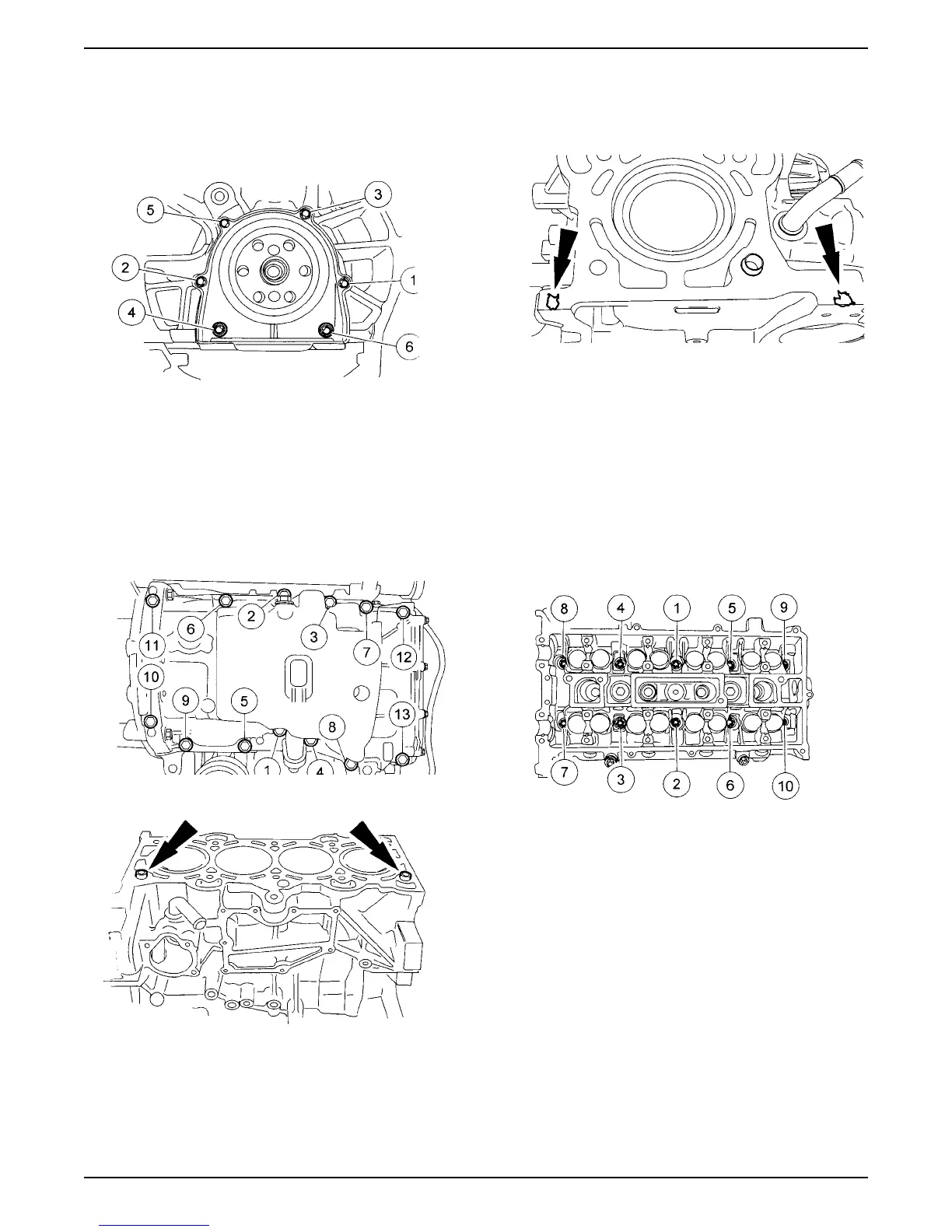

10.Install a new gasket and position cylinder head.

CAUTION: Do not reuse cylinder head bolts.

11.Lubricate new bolts and install in the sequence

shown in 5 stages:

• Stage 1: Tighten to 5 Nm (44 lb-in)

• Stage 2: Tighten to 15 Nm (11 lb-ft)

• Stage 3: Tighten to 45 Nm (33 lb-ft)

• Stage 4: Tighten an additional 90 degrees (1/4

turn)

• Stage 5: Tighten an additional 90 degrees (1/4

turn).

CAUTION: Install the camshafts with alignment

slots in the camshaft lined up so the camshaft

alignment plate can be installed without rotating the

camshafts. Make sure the lobes on the No.1

cylinder are in the same position as noted in the

disassembly procedure. Rotating the camshafts or

installing the camshafts 180 degrees out of position

can cause severe damage to the valves and pistons.

NOTE: Lubricate camshaft journals and bearing caps

with clean engine oil.

Loading...

Loading...