TORCH DATA 100i-400i 164 Manual 0560956430

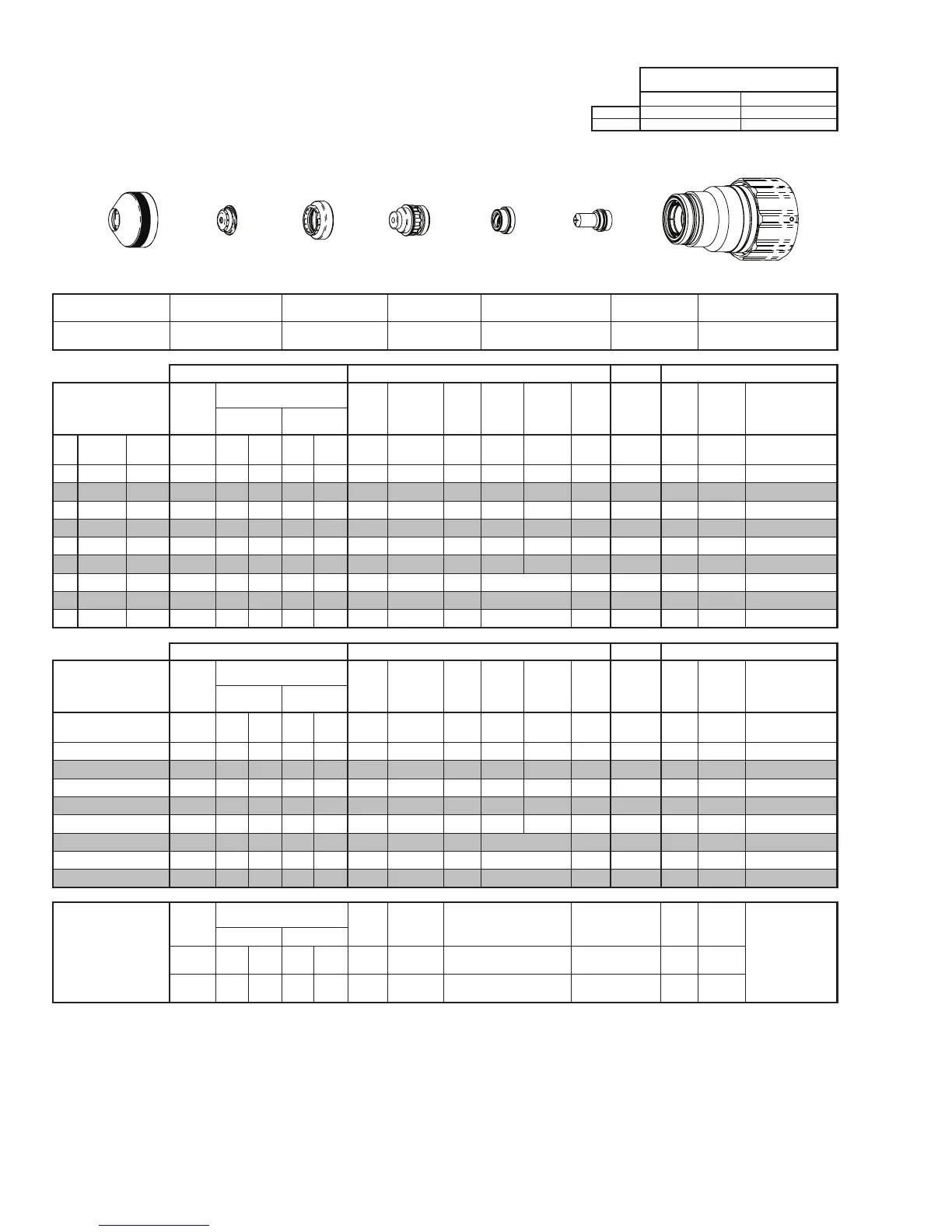

Aluminum

Flow Rates

200A

N₂ (SLPM / SCFH) H₂O (GPH / LPH)

Preow

13 / 28 5 / 19

N₂ Plasma / H₂O Shield

Culow

28 / 59 5 / 19

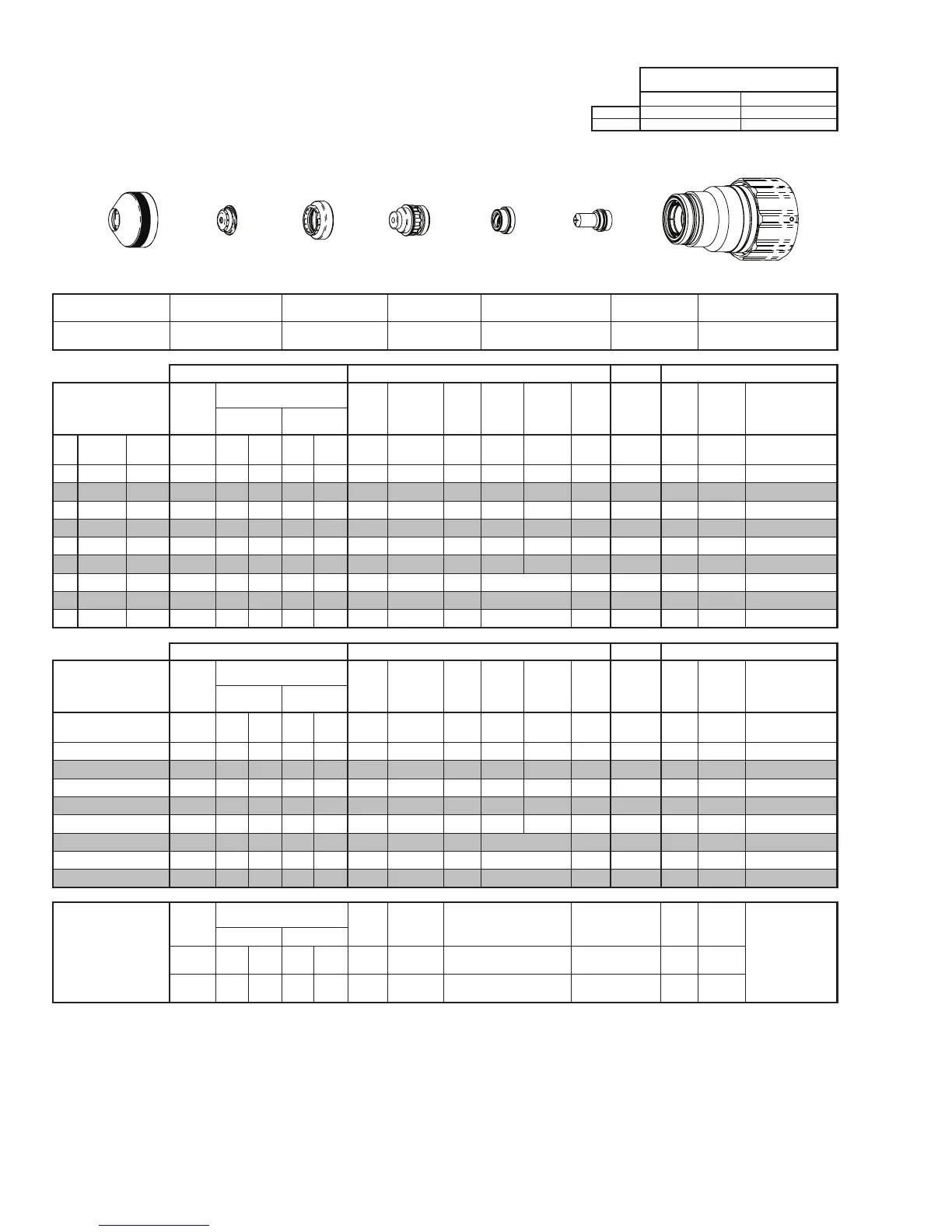

Cartridge

Electrode

Shield

Shield Gas

Distributor

Tip

Plasma Gas

Distributor

Shield Retainer

Art # A-07917_AC

This Art Is For Reference ONLY

Shield Retainer Shield Cap

Shield Gas

Distributor

Tip Plasma Gas Distributor Electrode Cartridge

0559211211 0559210150 0559210082 0559210129 0559210063 0559210107 0559211300

Manual Gas Control Advanced Torch Height Control (THC) Basic THC CNC Control

Material

Thickness

Pre Flow

Pressure

(N₂)

Cut Flow Rates / Pressures

Arc

Voltage

Cut Height

THC

Pierce

Delay

Pierce

Ignion

Height

Elevaon

Height

Control

Delay

Pierce

Height

without

Elevaon

Travel

Speed

CNC

Moon

Delay

Max Kerf Width

@ Rec. Speed

Plasma (N₂) Shield (H₂O)

ga (in) inch (psi) Ball (psi) Ball (psi)* (Volts) (in) ±0.005 (sec) (in) (in) (sec) (in) (ipm) (sec) (in)

- 1/2 0.500 20 100 90 5 55 168 0.250 0.3 0.200 0.150 0.2 0.300 110 0.3 0.120

- 5/8 0.625 20 80 100 5 55 170 0.300 0.7 0.250 0.200 0.2 0.350 105 0.5 0.126

- 3/4 0.750 20 80 100 5 55 175 0.300 0.9 0.250 0.200 0.2 0.350 90 0.6 0.127

- 7/8 0.875 20 80 100 5 55 180 0.300 1.2 0.250 0.200 0.2 0.350 75 0.8 0.133

- 1 1.000 20 80 100 5 55 194 0.350 1.6 0.300 0.250 0.2 0.400 50 1.0 0.144

- 1 1/4 1.250 20 80 100 5 55 208 0.400 3.4 0.350 0.300 0.2 0.450 25 2.0 0.180

- 1 1/2 1.500 20 80 100 5 55 210 0.400 0.8 Edge Start 0.2 Edge 20 0.8 0.197

- 1 3/4 1.750 20 80 100 5 55 212 0.400 0.8 Edge Start 0.2 Edge 18 0.8 0.201

- 2 2.000 20 80 100 5 55 215 0.400 0.8 Edge Start 0.2 Edge 12 0.8 0.204

Manual Gas Control Advanced Torch Height Control (THC) Basic THC CNC Control

Material

Thickness

Pre Flow

Pressure

(N₂)

Cut Flow Rates / Pressures

Arc

Voltage

Cut Height

THC

Pierce

Delay

Pierce

Ignion

Height

Elevaon

Height

Control

Delay

Pierce

Height

without

Elevaon

Travel

Speed

CNC

Moon

Delay

Max Kerf Width

@ Rec. Speed

Plasma (N₂) Shield (H₂O)

(mm) (Bar) Ball (Bar) Ball (Bar)* (Volts) (mm) ±0.1 (sec) (mm) (mm) (sec) (mm)

(mm/

min)

(sec) (mm)

12 1.4 100 6.1 5 3.8 168 6.1 0.2 4.8 3.5 0.2 7.3 2820 0.3 3.0

15 1.4 85 6.7 5 3.8 169 7.3 0.6 6.0 4.7 0.2 8.5 2700 0.4 3.2

20 1.4 80 6.9 5 3.8 176 7.6 1.0 6.4 5.1 0.2 8.9 2170 0.7 3.3

25 1.4 80 6.9 5 3.8 192 8.7 1.5 7.5 6.2 0.2 10.0 1350 1.0 3.6

30 1.4 80 6.9 5 3.8 204 9.8 2.9 8.5 7.3 0.2 11.1 810 1.7 4.3

35 1.4 80 6.9 5 3.8 209 10.2 0.8 Edge Start 0.2 Edge 530 0.8 5.0

40 1.4 80 6.9 5 3.8 211 10.2 0.8 Edge Start 0.2 Edge 490 0.8 5.0

50 1.4 80 6.9 5 3.8 215 10.2 0.8 Edge Start 0.2 Edge 320 0.8 5.2

Marking

Pre Flow

Pressure

(N₂)

Marking Flow Rates /

Pressures

Arc

Voltage

Marking

Height

Pierce Ignion Height

THC and CNC

Delay

Control

Delay

Travel

Speed

Marking quality

degrades as

thickness

decreases.

20A Arc Current

Plasma (N₂) Shield (N₂)

Burn-through may

happen for thicknesses

< 1/16” (0.063”) /

1.6 mm.

(psi) /

(Bar)

Ball

(psi) /

(Bar)

Ball

(psi) /

(Bar)

(Volts)

(in) ±0.005 /

(mm) ±0.1

(in) ±0.005 / (mm) ±0.1 (sec) (sec)

(ipm) /

(mm/ min)

15 / 1.0 80

60 /

4.1

NA

80 /

5.5

140 0.120 / 3.0 0.120 / 3.0 0 0.4

300 /

7620

BOLD TYPE indicates maximum piercing parameters. BOLD ITALIC indicates edge starts only.

* Pressure of the water supply line should be regulated by customer pressure regulator.

Note 1: Ohmic height sensing is not recommended with water shield. Water on the plate interferes electrically with the ohmic sensing circuit.

Note 2: Water source used for shield must be demineralized.

Loading...

Loading...