Functional characteristics

MIG/MAG welding

Item No.: 099-004833-EWM01 39

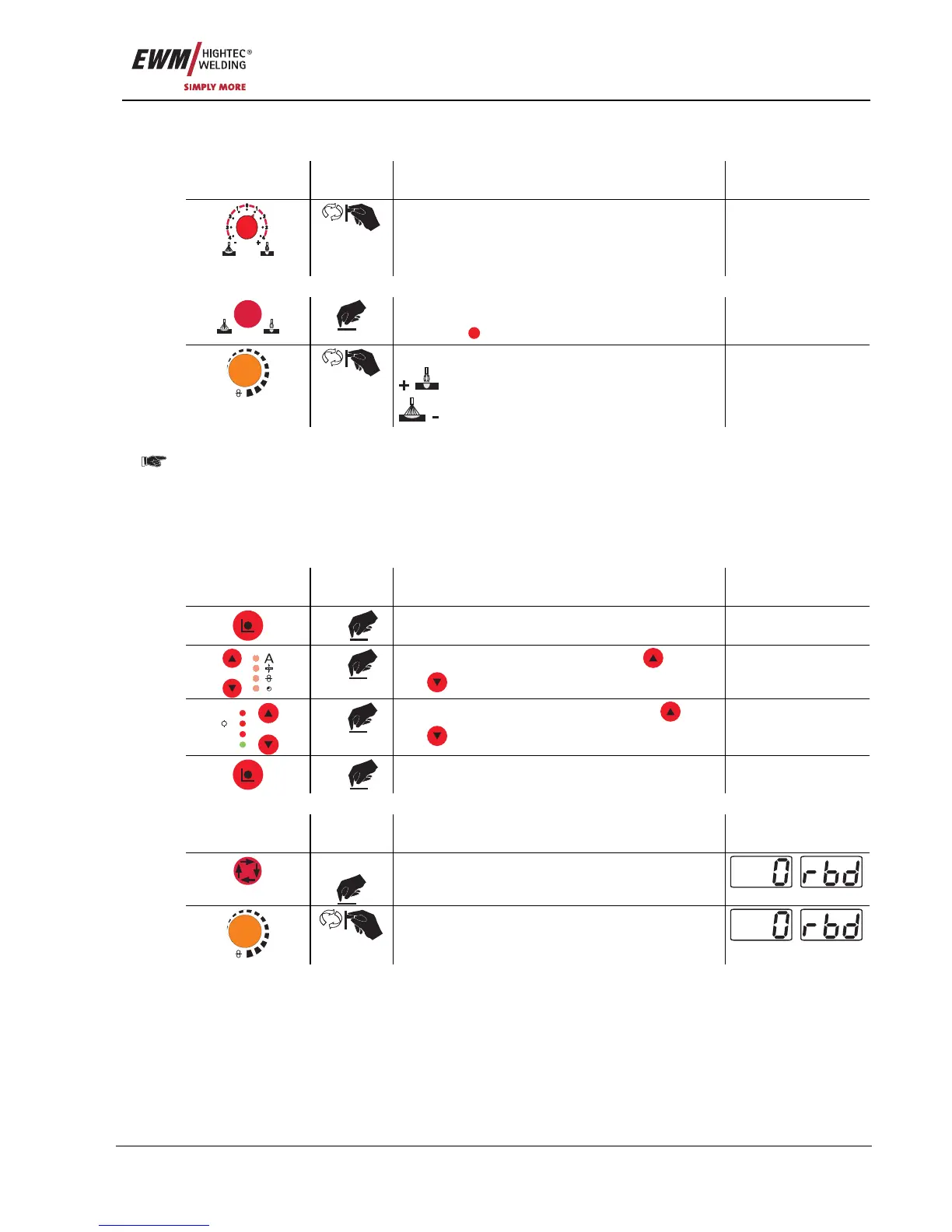

5.2.3.4 Choke effect / dynamics

PHOENIX DRIVE 4 M3.00

Operating

element

Action Result Display

"Dynamic correction/choke effect" rotary

switch

Dynamic correction or choke effect setting in 9

stages (hard, narrow to soft, wide arc)

No change

PHOENIX DRIVE 4 M3.7x

DYN

- +

Select Dynamics welding parameter

Dynamic"

DYN

comes on.

-40 to +40

m/min

Dynamics setting

Arc harder and narrower

Arc softer and wider

-40 to +40

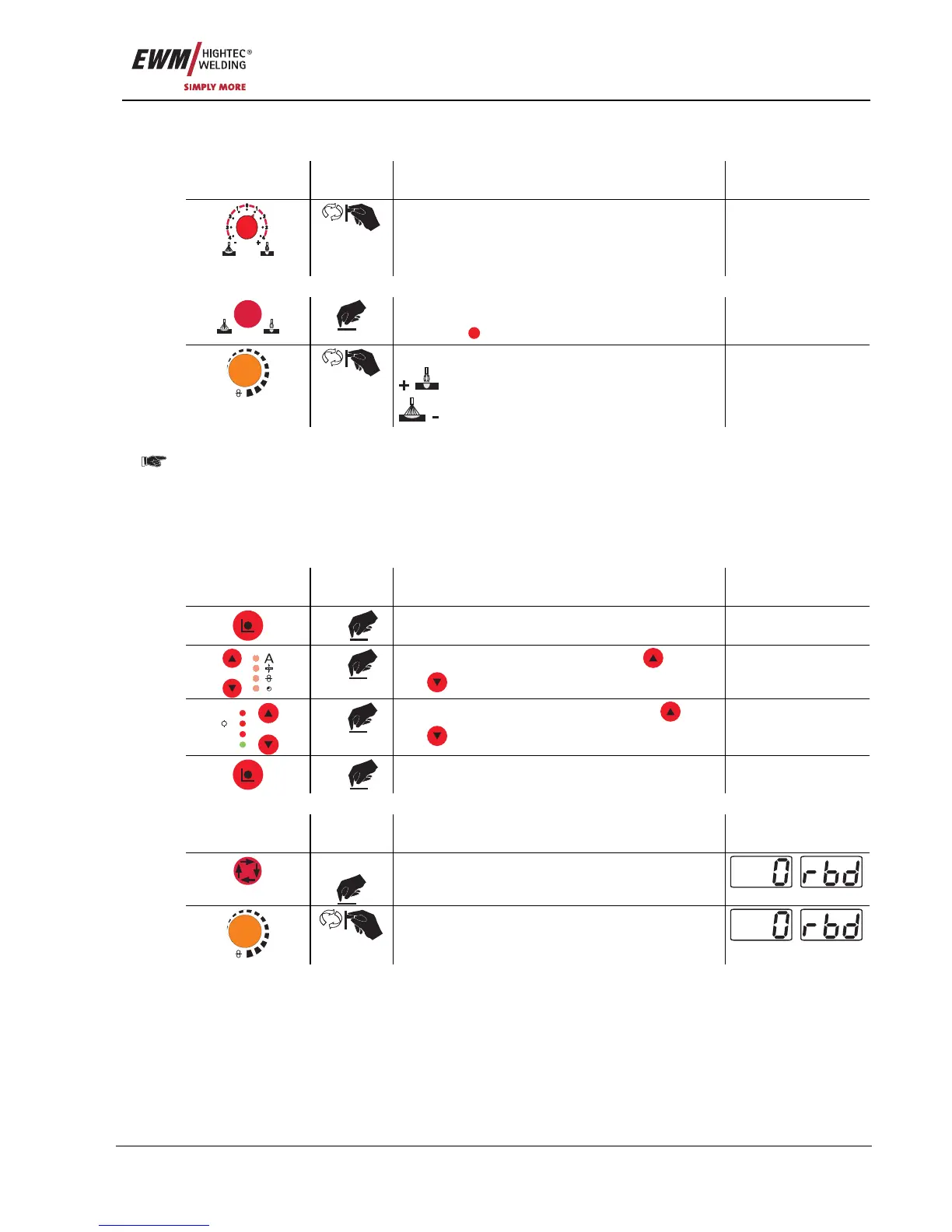

5.2.3.5 Wire burn-back

PHOENIX DRIVE 4 with M3.00 control:

• The settings for superpulses and wire burn-back are made on the M3.10 welding machine control

PHOENIX DRIVE 4 with M3.70 control:

• The settings for superpulses and wire burn-back are made either on the M3.10 welding machine

control or on the M3.71 wire feed unit control

M3.10:

Operating

element

Action Result Display

1 x

Select program sequence mode Program steps

x x

Select "RUECK" parameter using the

"Up"

and

"Down" buttons (left)

RUECK 2-500

V

Job Nr

Hold

A

M

x x

Adjust the selected parameter using the

"Up"

and

"Down" buttons (right)

RUECK 2-500

3 x

Machine returns to Display mode

M3.70:

Operating

element

Action Result Display

3 sec.

Selects wire burn-back

m/min

Parameter setting

(setting range 0 to 499)

Loading...

Loading...