Functional characteristics

TIG welding

70 Item No.: 099-004833-EWM01

5.3 TIG welding

5.3.1 TIG welding task selection

Control element Action Result Display

X x

The various welding processes are run through

until the signal light for the required welding

process comes on.

The nominal values

for the welding

current and welding

voltage are

displayed.

5.3.2 TIG welding current setting

The welding current is normally set using the “Wire speed” rotary dial.

Welding current is set The welding current

and voltage change

depending on the

setting

5.3.3 TIG welding data display

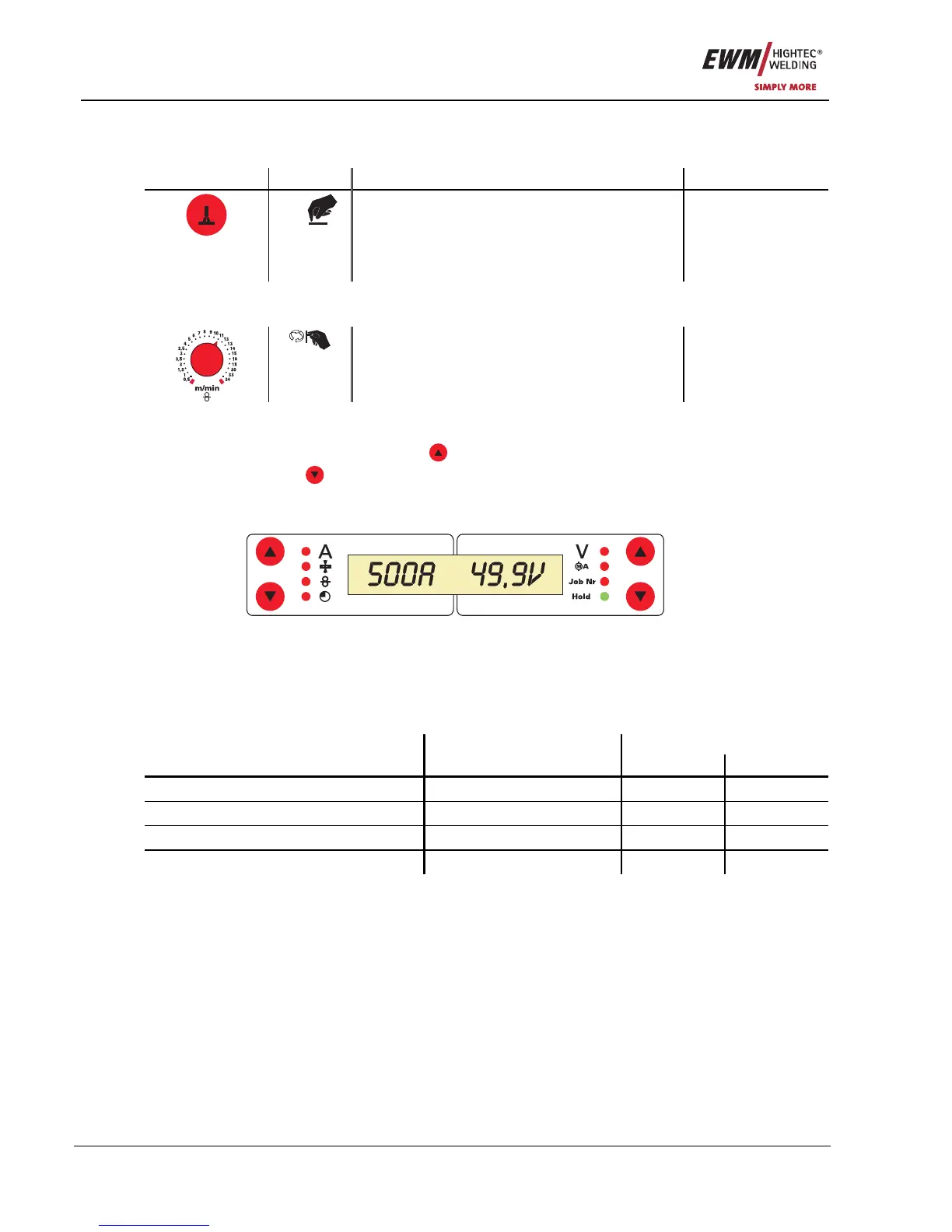

To the left and right of the LCD display on the control there are 2 “arrow keys” on each side for selecting

the welding parameter to be displayed. The

button is used to scroll through the parameters from the

bottom upwards and the

button is used to scroll downwards from the top.

As soon as changes have been made to the settings after welding (display on hold values), the display

switches back to the nominal values.

Figure 5-30

Four welding parameters can be selected in the TIG welding process:

Welding current and tungsten electrode diameter (left-hand side) and welding voltage and JOB no. (right-

hand side).

The parameters can be displayed before (nominal values), during (actual values) welding.

Parameter Before welding During welding

Nominal value Actual value Nominal value

Welding current

z z

Tungsten electrode diameter

z

z

Welding voltage

z z

JOB no.

z

Loading...

Loading...