Functional characteristics

MIG/MAG welding

Item No.: 099-004833-EWM01 67

5.2.11 MIG/MAG Push/Pull welding torch

The most important requirement for the greatest degree of efficiency and weld seam quality is the smooth

conveyance of the wire electrode. This is particularly problematic when:

• Longer tube packages are used,

• Wire electrodes have poor sliding properties,

• Wire electrodes have poor bending strength and

• An especially even wire outlet speed is required.

In this process, additional conveying aids in the torch produce significant improvements in comparison

with pure feed wire conveyors. In addition to a pushing wire feed (PUSH) in the power source / wire feed

case, a pulling wire feed (PULL) is used in the torch.

The two feed motors are synchronised by a current regulator.

Welding torches without potentiometers

Operating elements Functions

1 torch trigger Welding On/Off

Push/Pull torch with one potentiometer

Infinitely adjustable setting of welding performance (Up/Down function)

Changeover switch in WF unit to "Up / Down" (see "Internal operating elements" chapter)

Operating elements Functions

1 torch trigger Welding On/Off

1 rotary dial Infinite adjustment of the wire speed

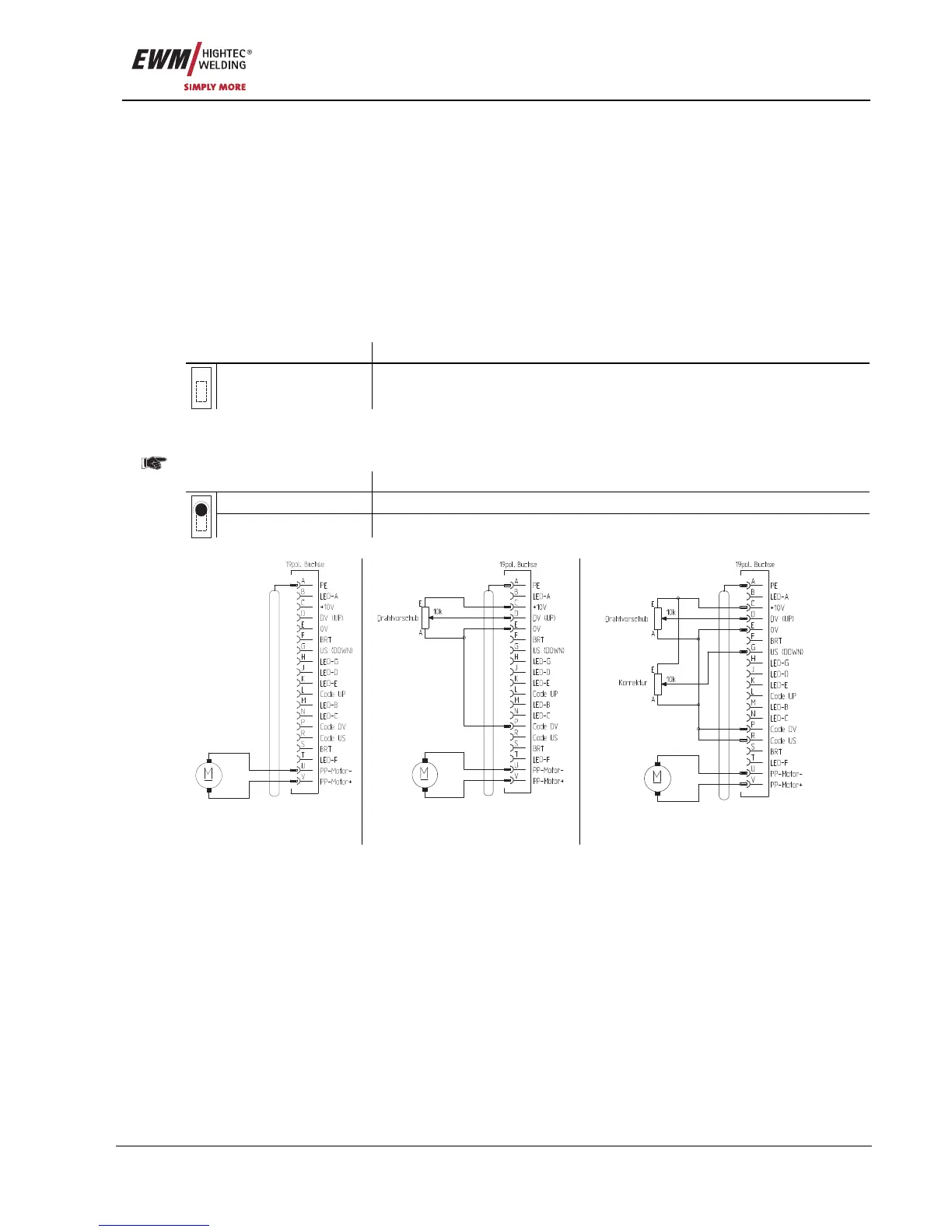

5.2.11.1 Pin assignments

No potentiometers

With potentiometer for wire

feeding speed

With potentiometers for wire feeding

speed and arc length correction

Figure 5-29

Loading...

Loading...